Portable hoisting device

A hoisting device and lightweight technology, applied in the directions of portable hoisting devices, hoisting devices, cranes, etc., can solve the problems of inconvenient assembly and transportation, cumbersome equipment, etc., and achieve the effects of simple structure, strong lifting ability and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

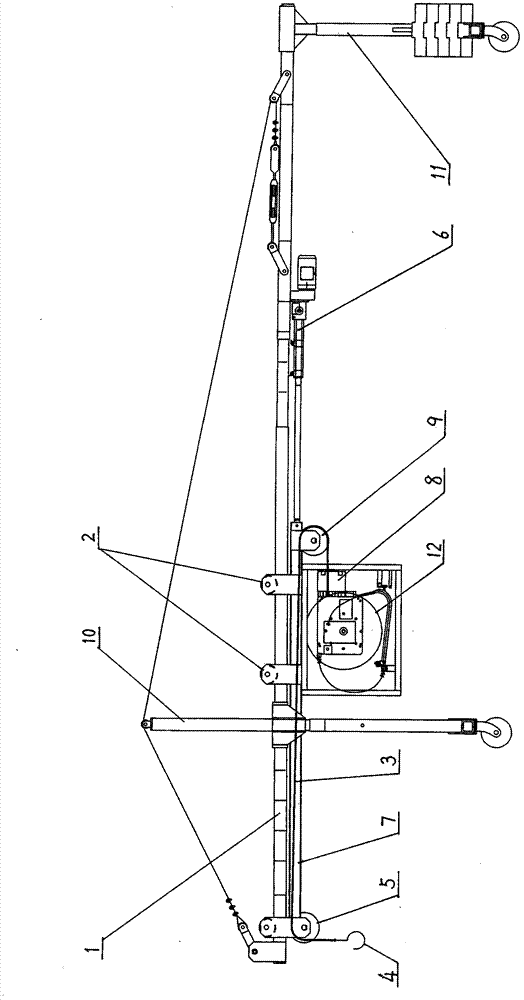

[0039] Such as figure 1 A kind of portable lifting device shown, comprises the suspension beam 1 that is horizontally arranged on the front bracket 10 and the rear bracket 11 and the hoisting mechanism that is arranged on the suspension beam 1, and described hoisting mechanism comprises steel wire rope 3, and described hoisting mechanism also includes A boom 7 that is arranged below the suspension beam 1 and is rollingly connected with the suspension beam 1 through the roller 2, fixed pulley 1 5 is installed on the front end of the boom 7, and fixed pulley 2 9 is installed on the rear end of the boom 7. The boom 7 between the first pulley 5 and the second fixed pulley 9 is fixedly provided with a hoist 8 through the frame, and the front end of the wire rope 3 bypasses the second fixed pulley 9 and the first fixed pulley 5 to connect with the hook 4 successively. The rear end is connected to the cable take-up mechanism 12 installed on the frame by a hoist 8, and the suspension ...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is that the cable receiving mechanism 12 is a dynamic cable receiving mechanism, and other structures are the same as in embodiment 1.

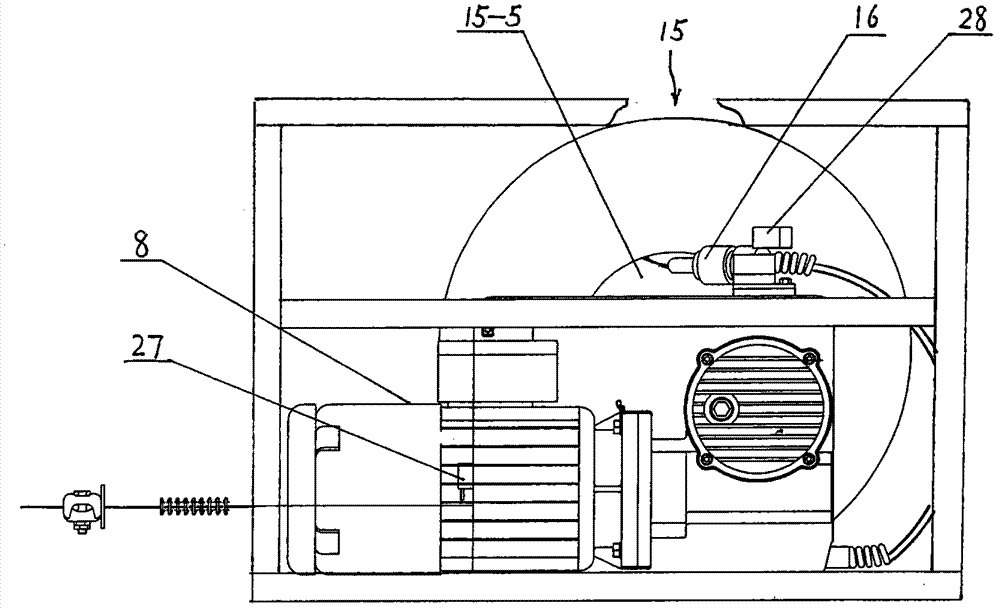

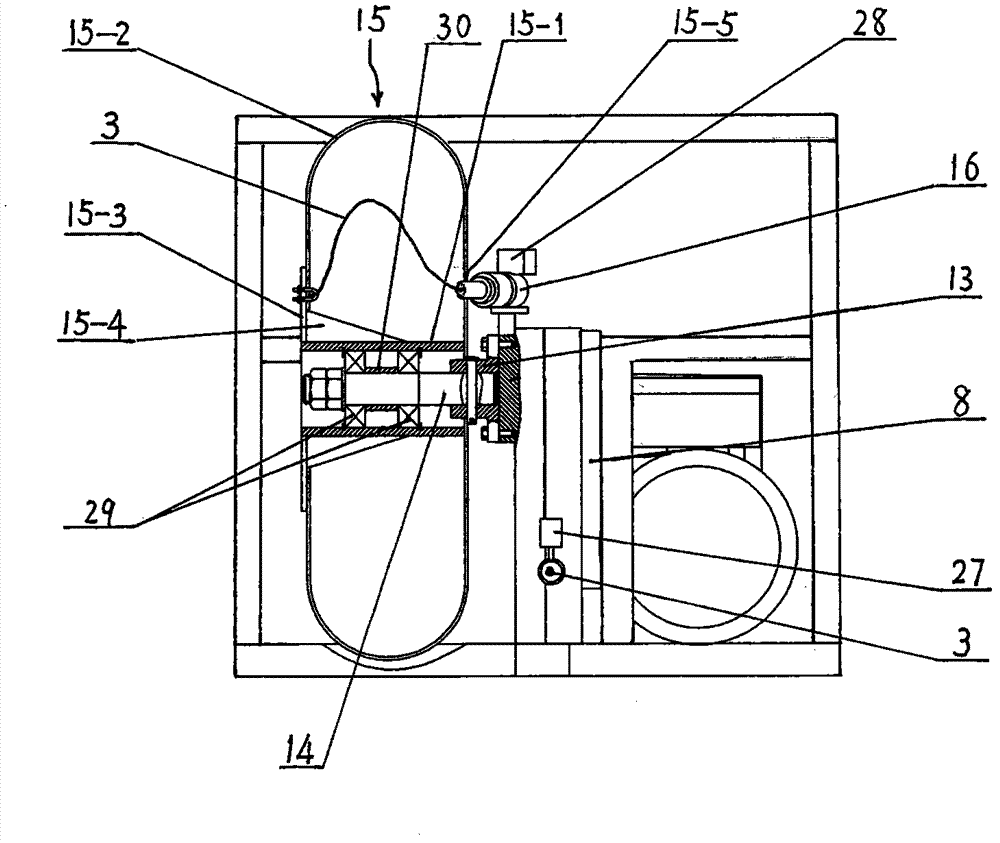

[0046] Figure 4 and Figure 5 Shown is a dynamic cable take-up mechanism, comprising a rotating shaft 18 driven by a hoist 8 and an open cable reel 19 arranged on the rotating shaft 18. One end of the rotating shaft 18 is connected to the hoisting machine 8, and the other end of the rotating shaft 18 passes through a bearing 20 Connected with the frame, the middle part of the rotating shaft 18 is provided with a cable reel connection mechanism 21, the open cable reel 19 is connected with the rotating shaft 18 through the cable reel connection mechanism 21, the open cable reel 19 is provided with a brake 22, the hoist 8 and A guide tube 17 with a wire rope guide head 16 at one end is arranged between the open cable reels 19, one end of the guide tube 17 is rotated on the frame thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com