Vacuum glass with real-time detectable vacuum performance

A real-time detection and vacuum glass technology, applied in vacuum gauges using ionization effects, vacuum gauges that measure medium pressure by measuring changes in medium thermal conductivity, etc., to ensure the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The accompanying drawings disclose the specific structures of the embodiments of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

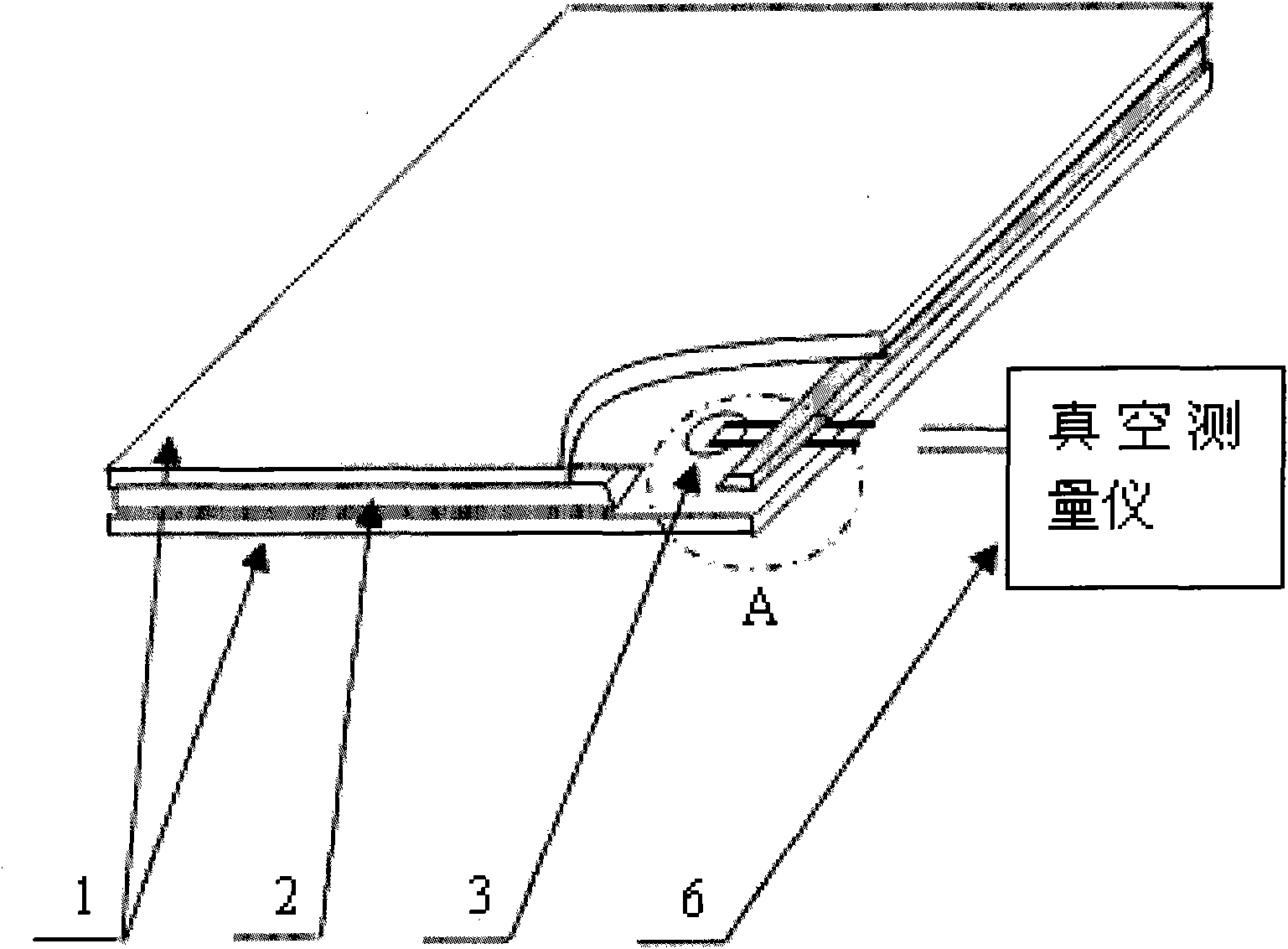

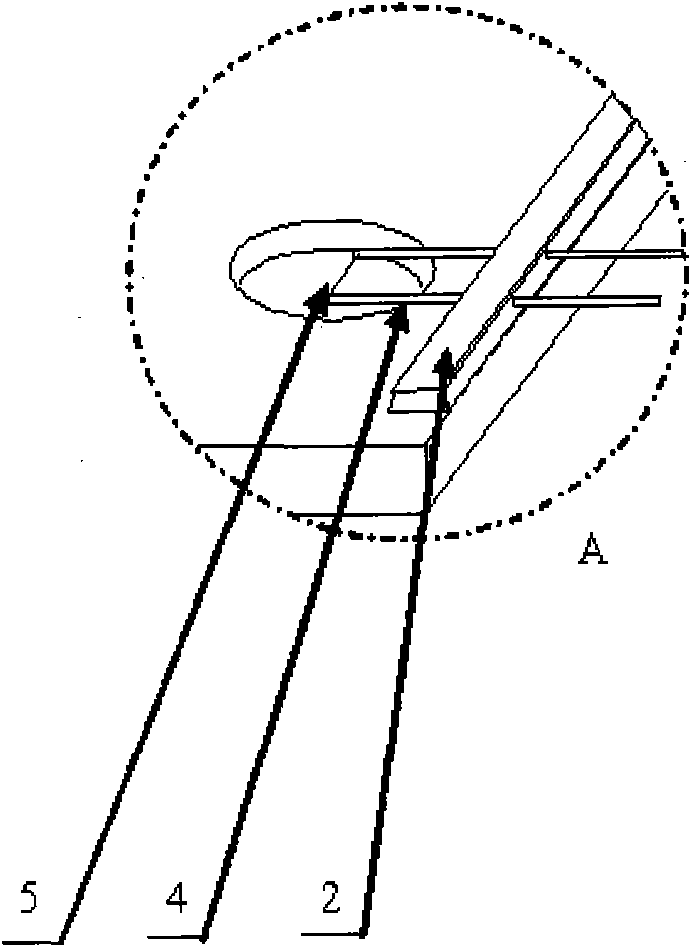

[0027] Depend on figure 1 figure 2 It can be seen that the present invention is a vacuum-sealed cavity formed by two layers of glass 1 and a heat-insulating sealing material 2 along the periphery of the glass 1. Evenly distributed equal-height heat-insulating support columns are arranged between the two layers of glass 1, and a vacuum degree is set in the vacuum-sealed cavity. Measuring point 3, the vacuum degree measuring point 3 is fixedly installed with a vacuum degree measuring probe 5, and the lead wire 4 of the vacuum degree measuring probe 5 passes through the heat insulating sealing material 2. During detection, the lead wire 4 is connected with the vacuum measuring instrument 6 .

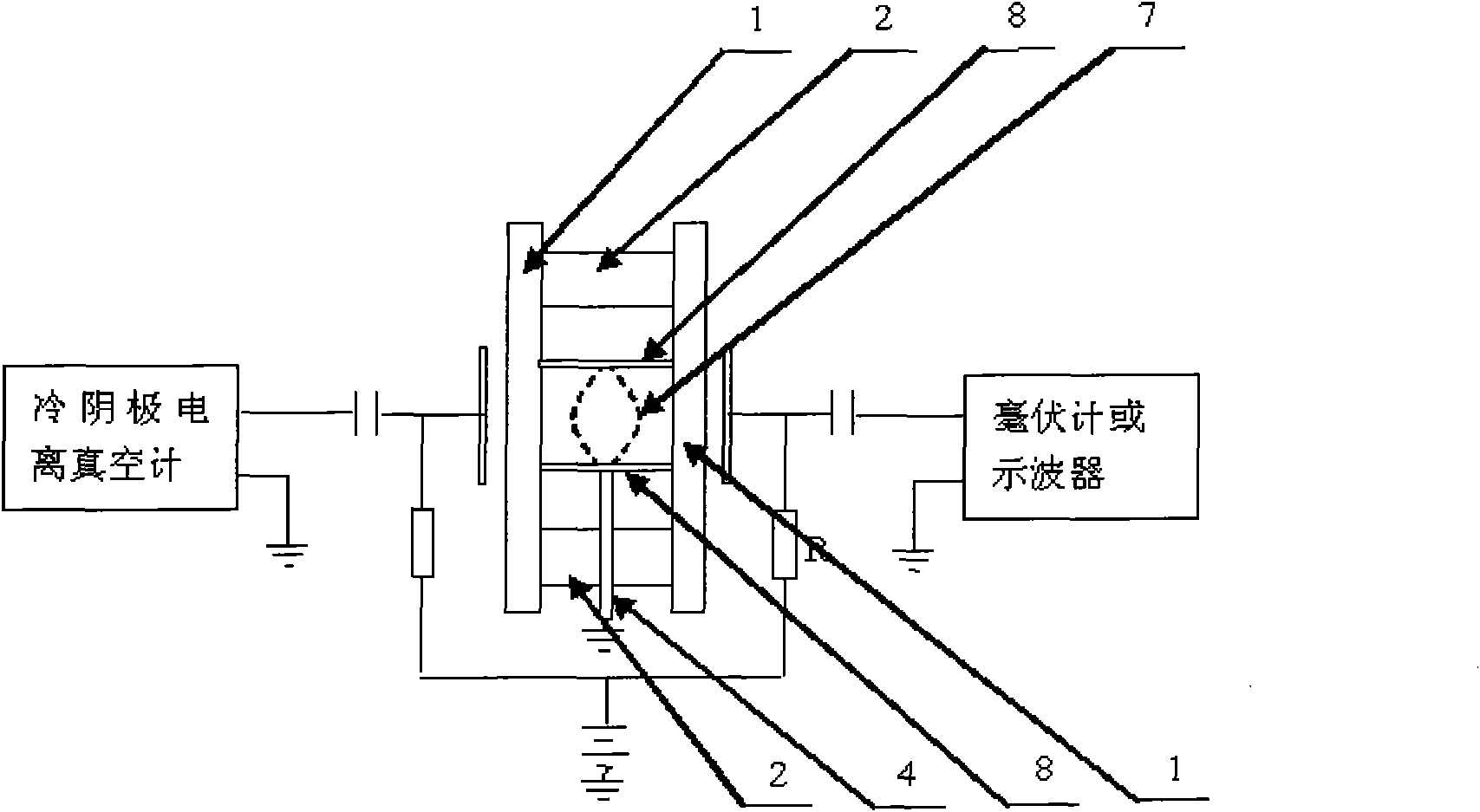

[0028] Depend on image 3 It can be seen that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com