Complementary slurry distributor of headbox

A pulp distributing device, complementary technology, applied in the direction of textiles and papermaking, paper machine, paper machine wet end, etc., can solve the problem of uneven distribution of pulp, and achieve the effect of simple structure, uniform pulp distribution and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

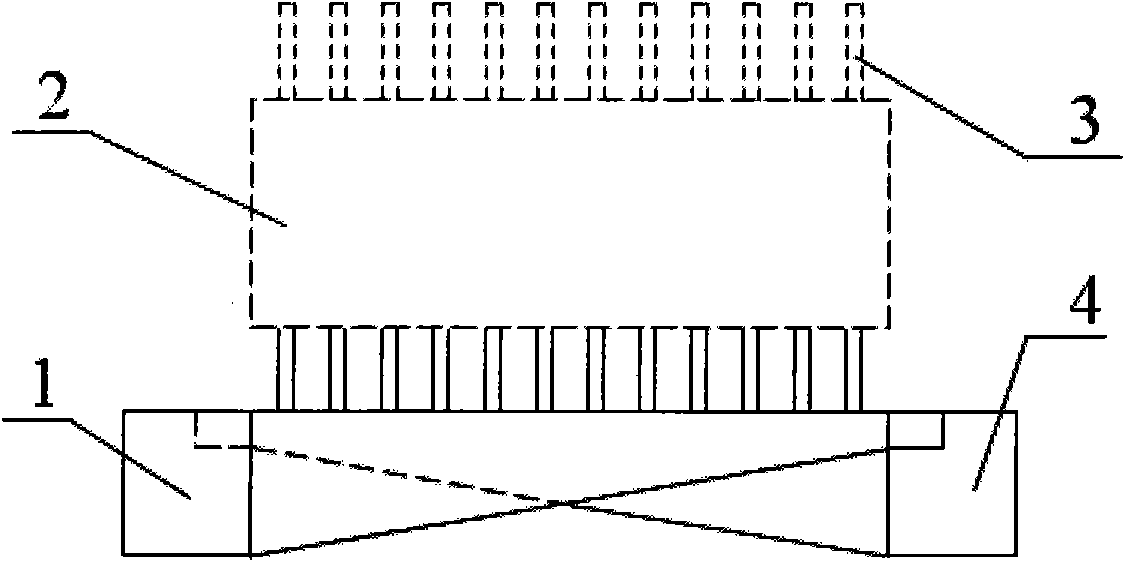

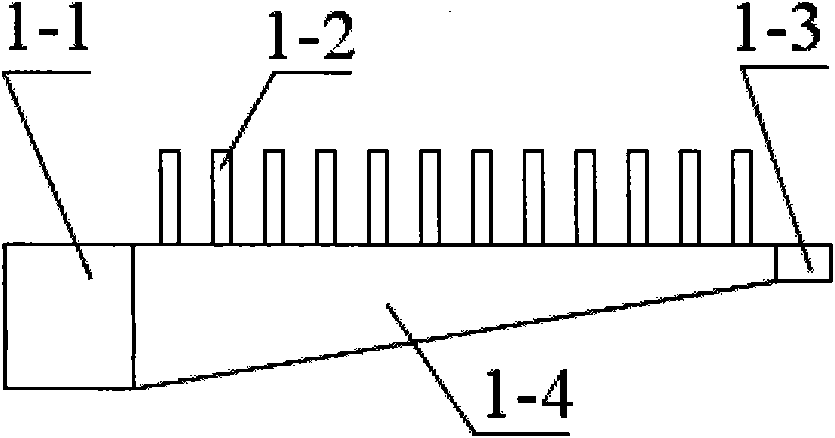

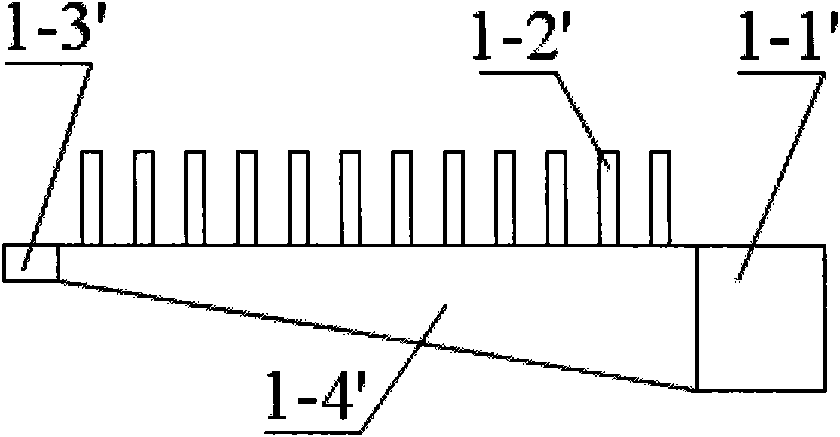

[0015] Such as figure 1 As shown, during installation, the transition pipe 1-1, square cone pipe 14, return pipe 1-3 and branch pipe bundle 1-2 are first assembled into a square cone pipe slurry distributor 1, and the transition pipe 1-1', square cone The pipe 1-4', the return pipe 1-3' and the branch pipe bundle 1-2' are assembled into a square cone tube slurry distributor 4, and then, the square cone tube slurry distributor 1 and 4 are stacked together up and down, left and right symmetrical, They are not connected to each other and are installed at the entrance of the headbox. When working, the pulp passes through the transition pipes 1-1 and 1-1' of the two square cone main pipes arranged symmetrically, and enters into the square cone main pipe 1-4 and 1-4' from the tapered pipe inlet, and the return pulp is fed by two The return port flows out in the opposite direction and enters the stock tank, and the rest of the pulp flows out from the branch tube bundles 1-2 and 1-2'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com