Dam grout stopping body and arranging method thereof

A layout method and grouting technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of long construction work, time lapse, and short contact grouting construction work, so as to facilitate concrete vibration compaction, The effect of improving concrete quality and shortening the straight-line construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

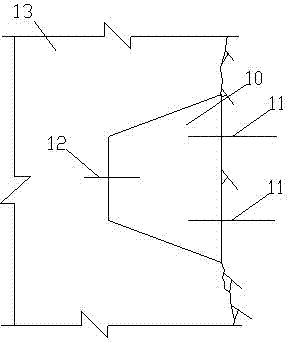

[0031] Such as Figure 6 As shown, a specific structure of a grout-stop body, according to the size and longitudinal section in the figure, a shaped steel formwork is made in sections of every 1.5m for pouring the grout-stop concrete structure 10, when the concrete reaches a certain strength (generally 2~3d age period) to remove the formwork; the dimensions of the trapezoidal concrete structure 10 of the grout stop: height A=400mm, upper bottom width B=300mm, lower bottom width C=500mm, the size and width of the grout stop middle groove 16 D= 30mm, depth E=25mm, the length of the grout stop is determined according to the site area division requirements, and 2~3 coats of asphalt are applied to the top and both sides of the trapezoidal concrete structure 10 of the grout stop to form a 2~3mm thick asphalt layer 18.

[0032] Such as Figure 5 As shown, a water-swellable rubber 17 with a width of 30mm and a thickness of 50mm is embedded in the groove 16, and the water-swellable r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com