Method for over-speed protection of turbine under load shedding working condition

A technology of overspeed protection and steam turbine, which is applied to mechanical equipment, engine components, machines/engines, etc. It can solve the problems of many OPC actions and high secondary speed, so as to ensure safe and stable operation, stable speed as soon as possible, and ensure grid power supply safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

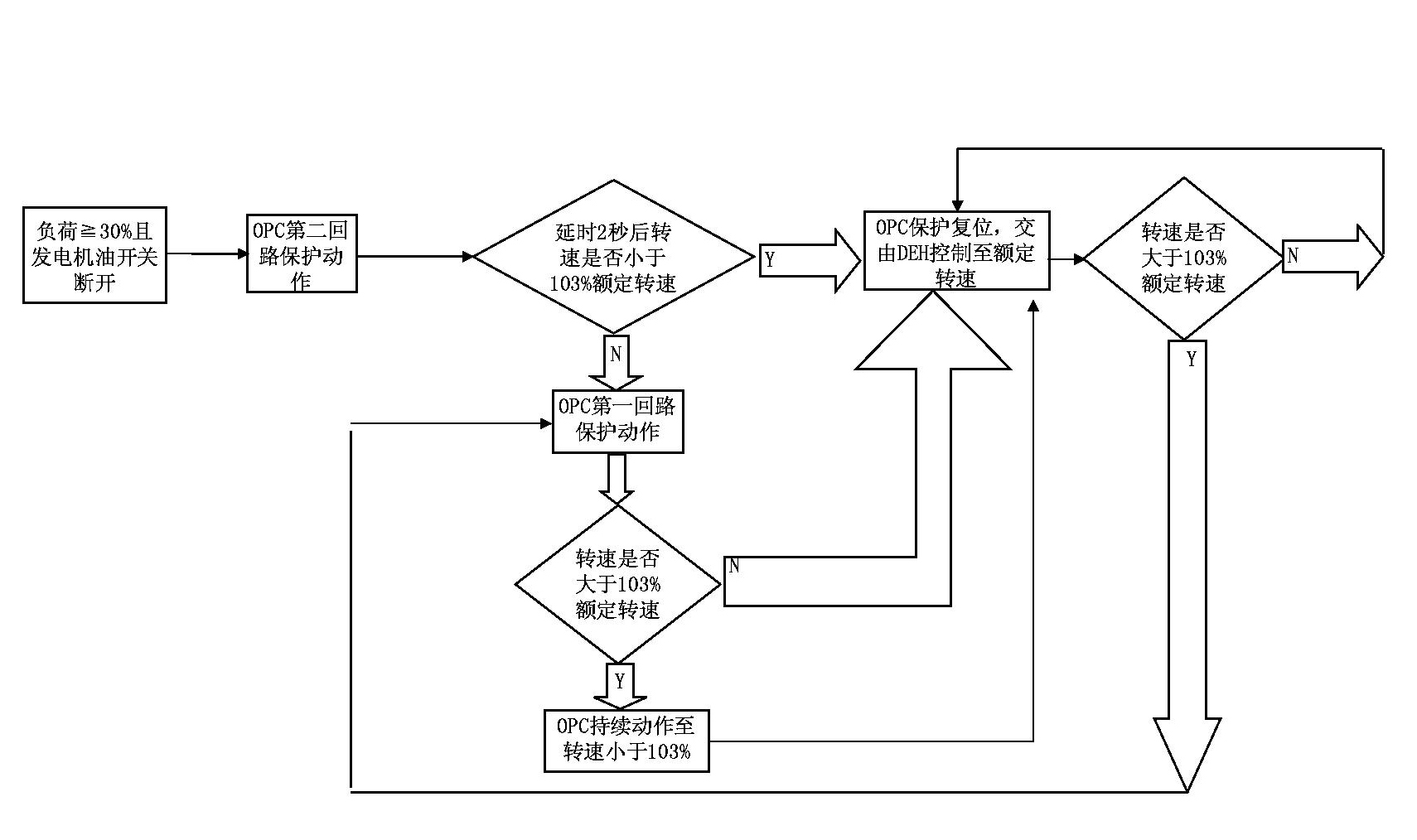

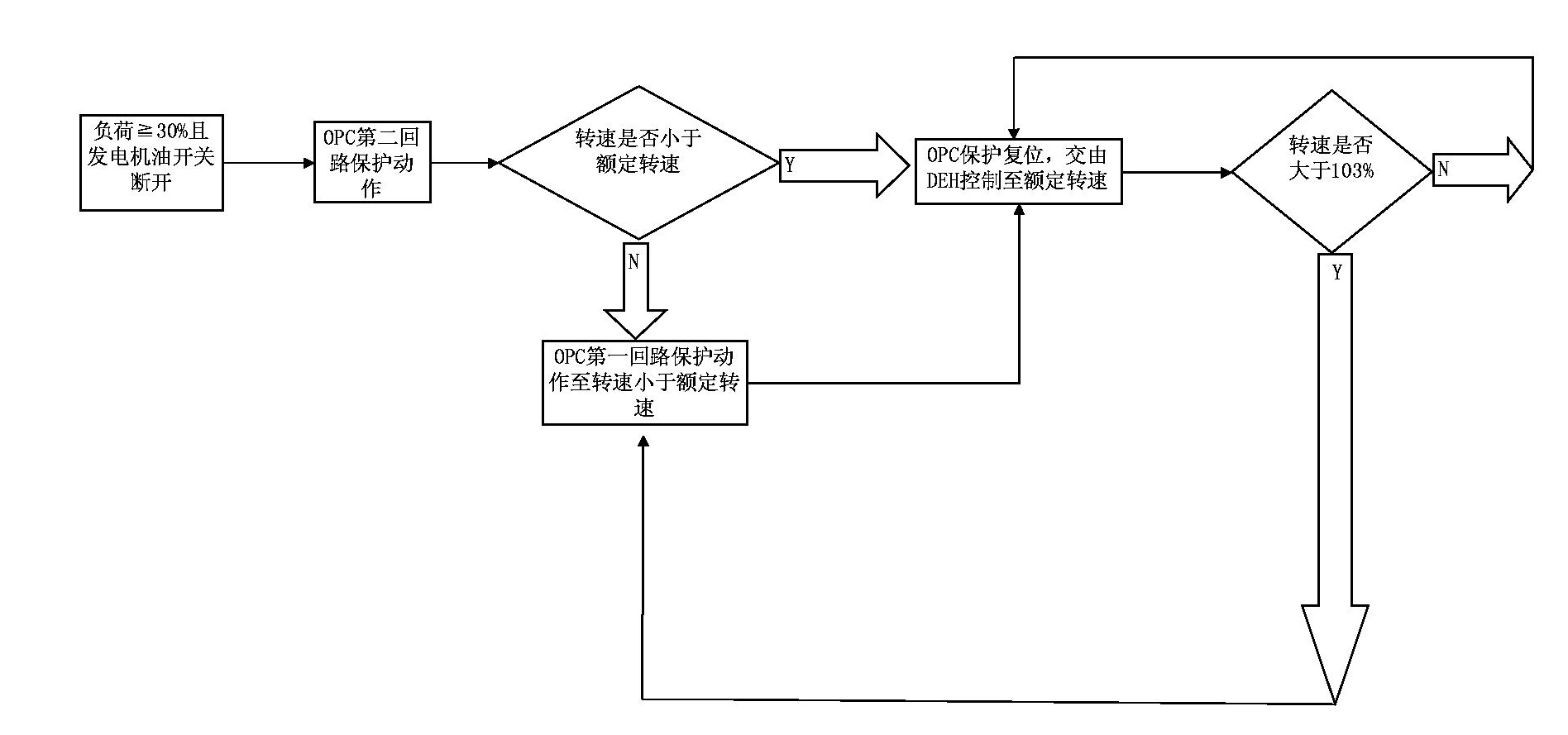

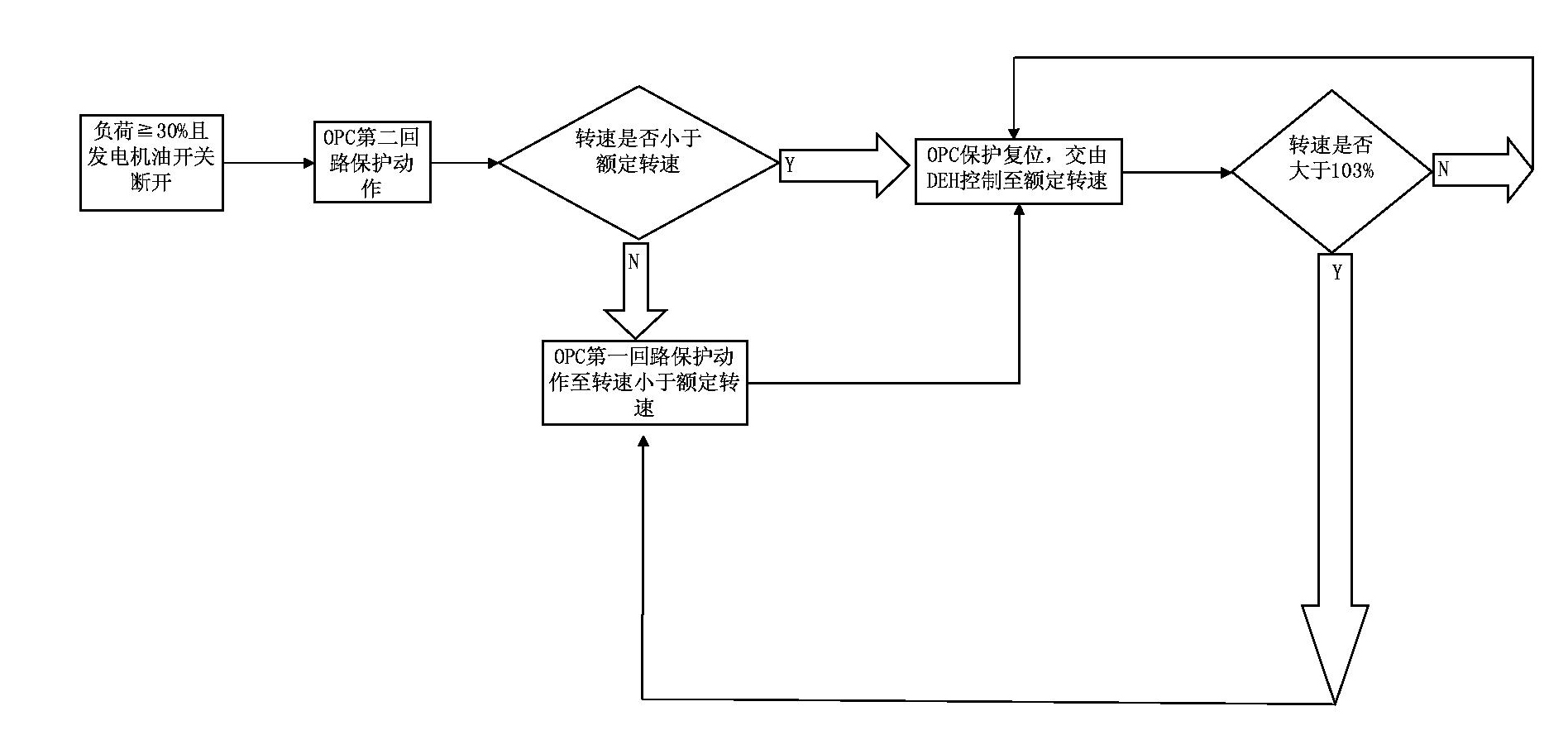

[0017] Such as figure 2 As shown, the method for the overspeed protection of the steam turbine under load shedding condition of the present invention utilizes the existing DEH system and OPC system. OPC has two circuits: the second circuit, when the load of the unit is ≥30% of the rated load and the generator oil switch is disconnected, DEH triggers the OPC action, and the OPC forcibly closes the regulating valve quickly to prevent the excessive increase of the speed. <Rated speed, DEH triggers OPC to reset, and the turbine speed is controlled by DEH to rated speed. In the first circuit, when the speed of the steam turbine is ≥103% of the rated speed, the OPC acts, and the OPC forcibly closes the regulating valve quickly to prevent the excessive rise of the speed. When the speed of the steam turbine is less than the rated speed, DEH triggers the OPC to reset, and the speed of the steam turbine is handed over to DEH Control to rated speed.

[0018]It can be seen that the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com