Filter belt self balance deviation rectifying device

A deviation correcting device and self-balancing technology, which is applied in dehydration/drying/thickened sludge treatment, etc., to avoid edge bending, improve service life, and reduce the number of actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

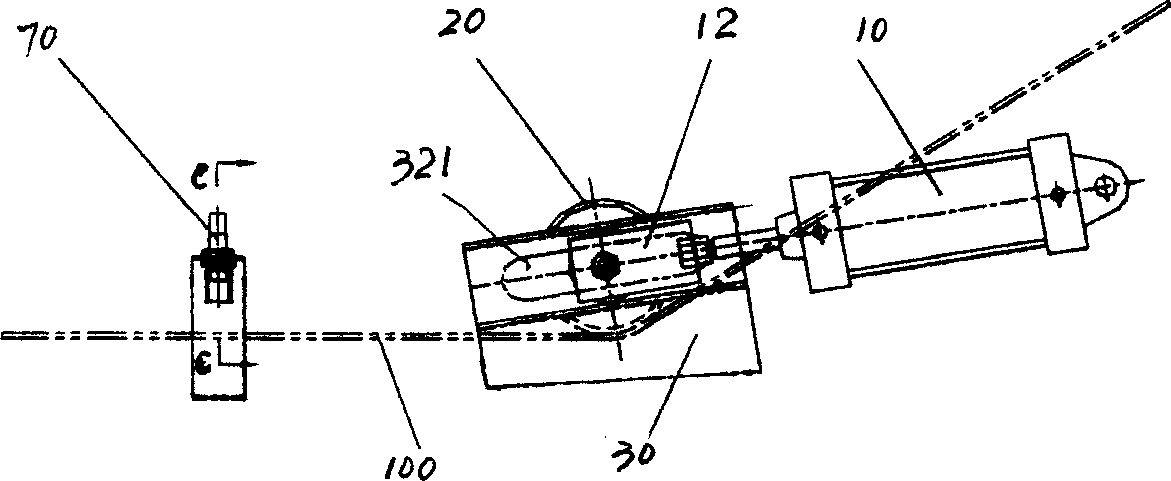

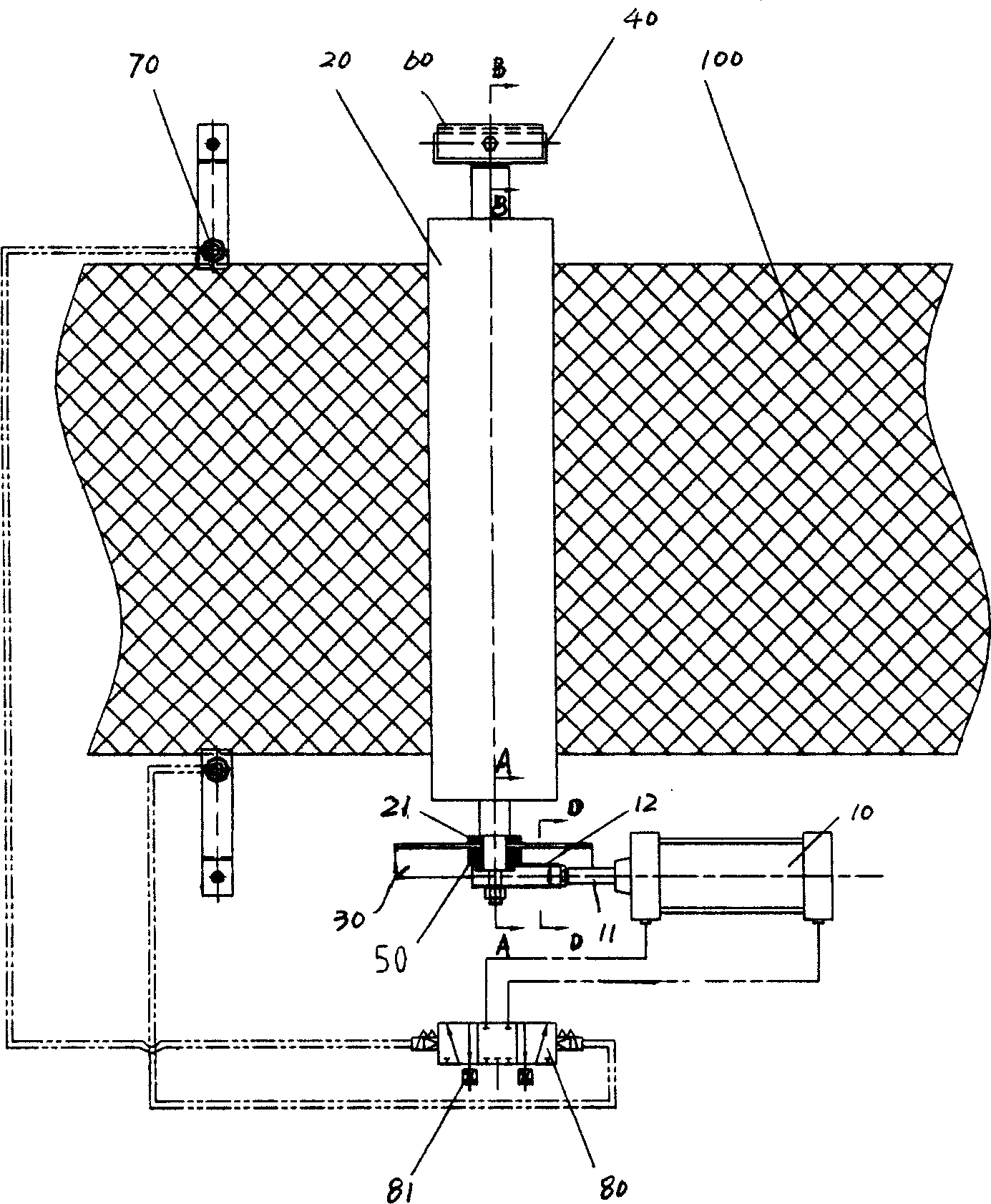

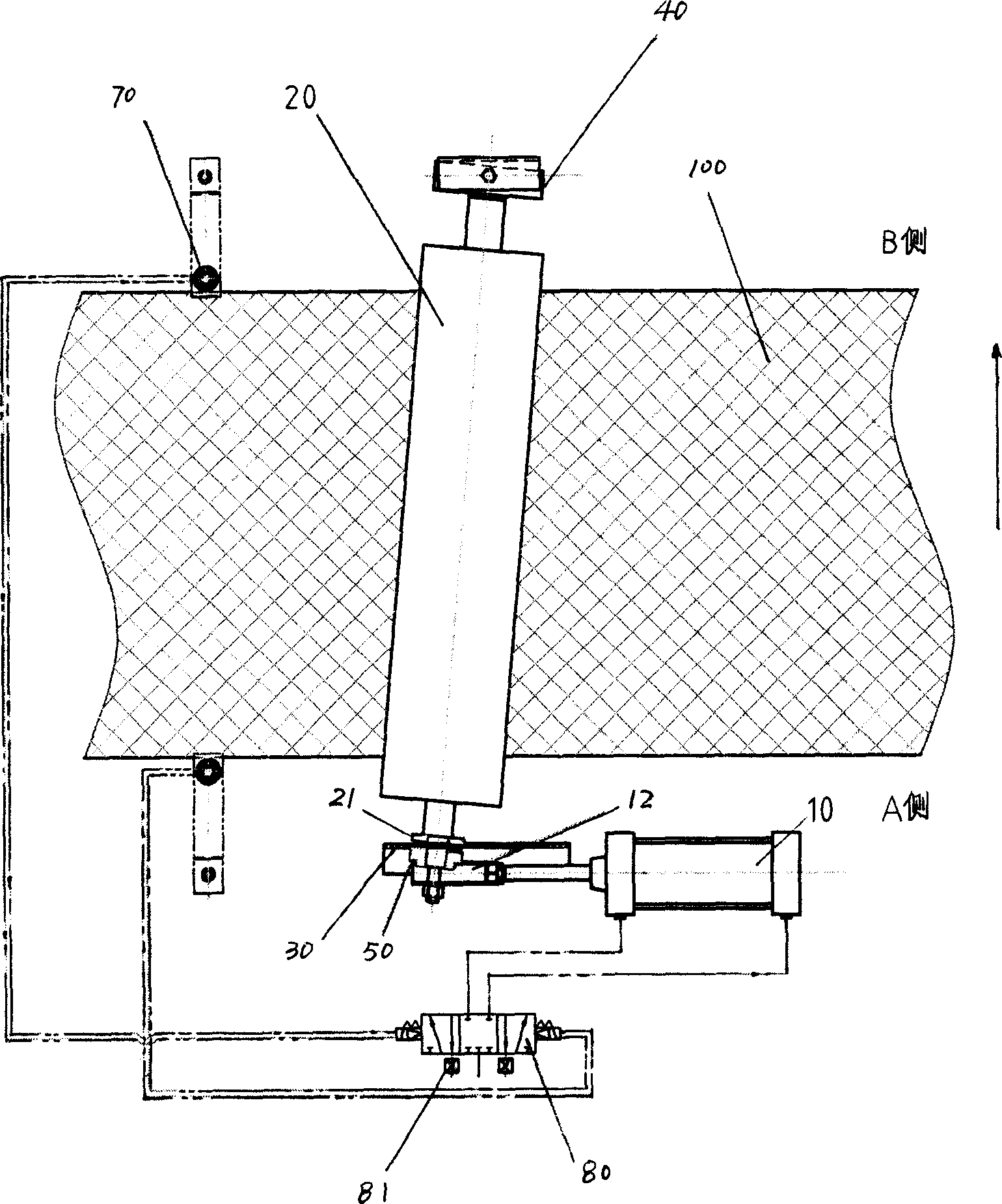

[0027] Such as figure 1 , 2 , 3, the filter belt self-balancing correction device disclosed by the present invention includes a correction actuator and a correction signal device, the electromagnetic reversing valve 80 of the correction signal device is connected with the cylinder 10 of the correction actuator through a gas pipe, and the cylinder 10 is arranged in the filter On the side of the belt, the deviation-correcting roller 20 is placed horizontally on the filter belt 100, and one end shaft head of the deviation-correcting roller 20 is connected with a roller 50, and the roller 50 rolls back and forth along the rail frame 30 fixed on the frame, and the deviation-correcting roller 20 The other end is arranged on the fixed support 60 through the sliding bearing 40 .

[0028] Such as Figure 4 , 8 , 9, the cross-section of the guide rail frame 30 is F-shaped, and the two parallel strips 31, 32 on its top constitute the guide rail portion for the roller 50 to roll, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com