Acid pump

A technology for acid pumps and pump shafts, which is applied in the field of special acid pumps, can solve the problems that affect the working safety and service life of acid pumps, cannot prevent the escape of acid gas, and the harsh working environment, etc., and achieve outstanding substantive features, sealing The effect of good performance, ensuring work safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

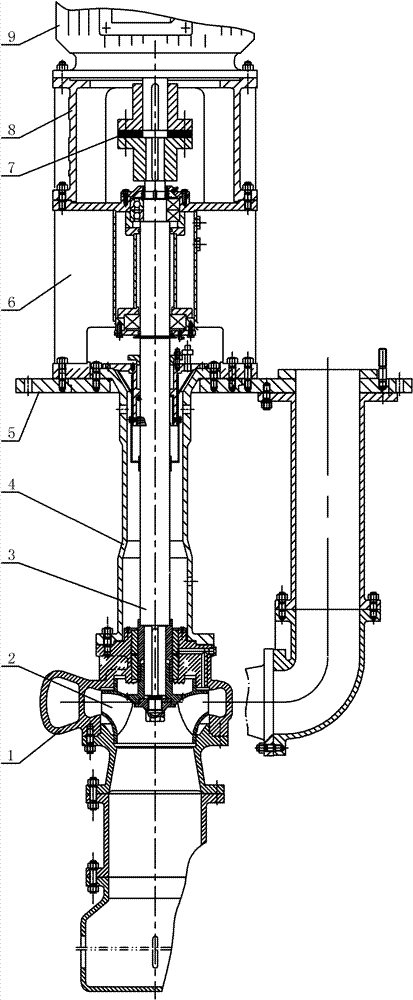

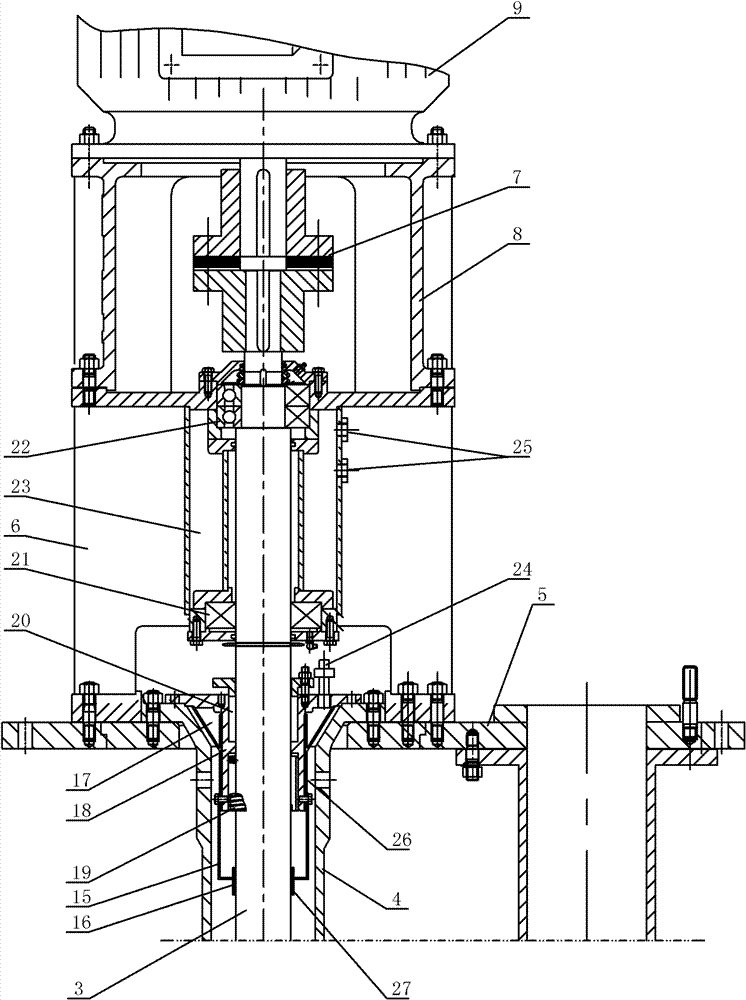

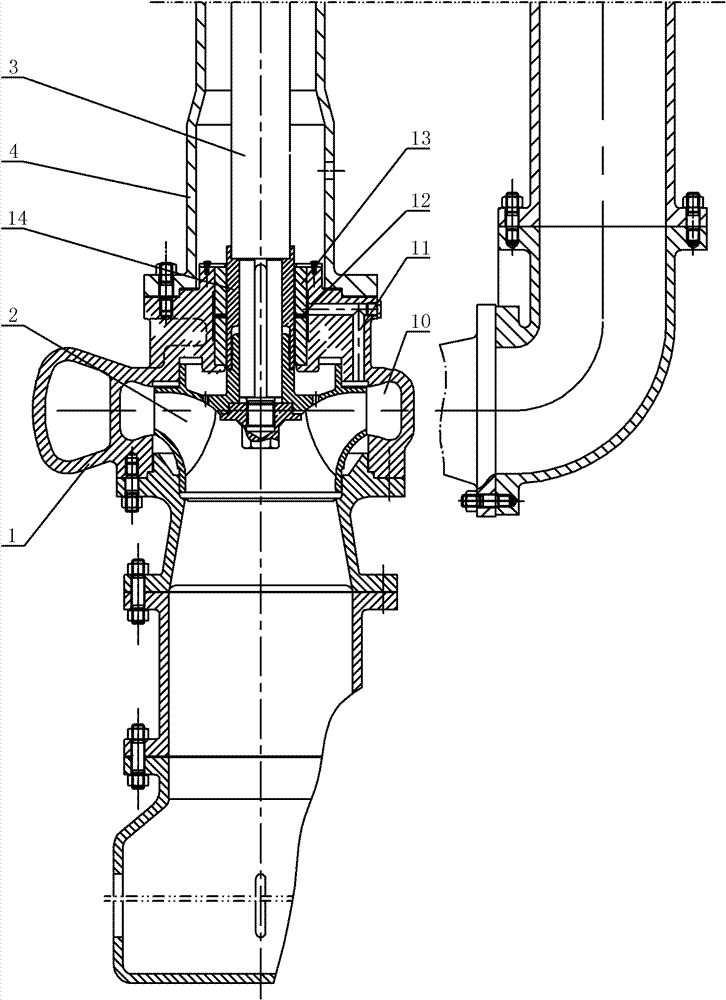

[0015] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] Refer to attached figure 1 , 2 , 3, the acid pump of the present invention is a special pump in the acid low temperature recovery system, including the pump shaft 3 connected to the acid pump impeller 2, the impeller 2 is arranged in the pump body 1, and the pump shaft 3 passes through the pump body 1 A bushing 13 and a bushing 14 are provided. The inner hole of the bushing 13 and the outer circle of the bushing 14 are rotating mating surfaces. The bushing 13 is fixed on the pump body 1, and the bushing 14 is fixed on the pump shaft 3. The bushing The outer circle of the inner hole of 13 is provided with a through hole 12, and the through hole 12 is connected to the outlet 10 of the acid pump through the guide hole 11 provided on the pump body 1; the pump shaft 3 passes through the overhanging part of the pump body A casing 4 is set, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com