Device and method for detecting product pipeline leakage condition

A product pipeline and detection device technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of undetectable, poor effect, and abnormal operation of equipment, and solve the problem of poor sealing , Simple and clear operation, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

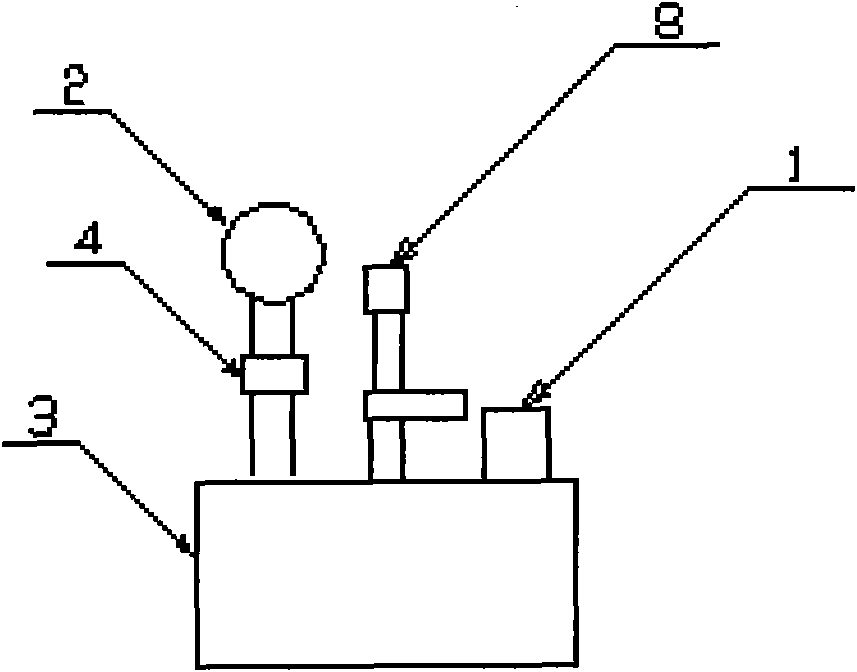

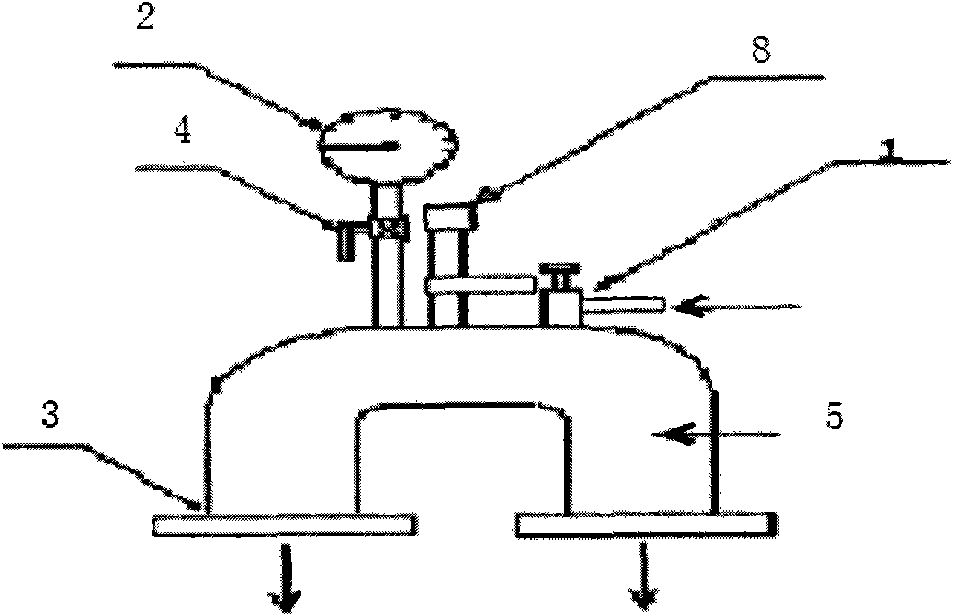

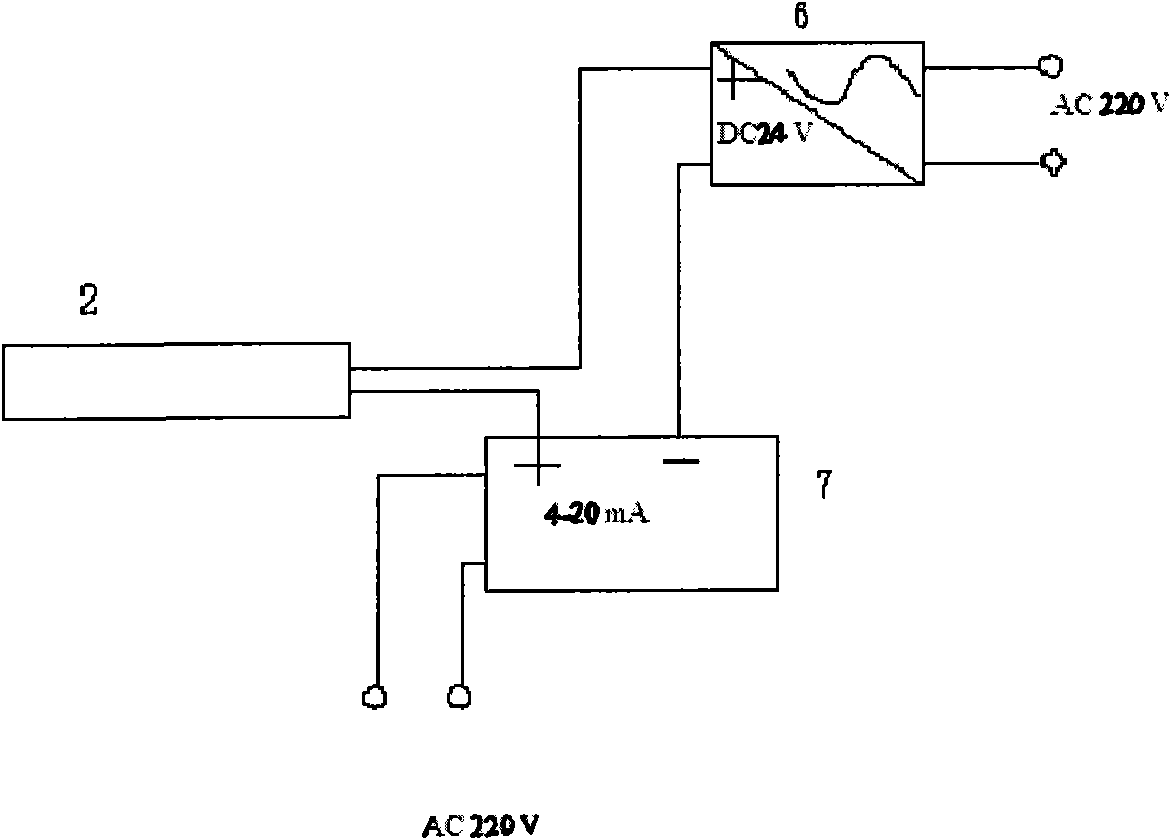

[0036] like figure 1 , 2 As shown, the present invention includes a throttle valve 1, a pressure transmitter 2, a connection assembly 3, a ball valve 4, a tubular body 5, a pressure transmitter power supply 6, a recorder 7, a safety valve 8 and a blind plate assembly 9, wherein the ball valve 4 is set between the pressure transmitter 2 and the tubular body 5, such as image 3 As shown, the pressure transmitter 2 is connected to the pressure transmitter power supply 6 and the recorder 7; wherein the blind plate assembly includes a blind plate, a gasket, a pipe clamp or a joint, such as Figure 4 As shown, the blind plate assembly is used to screw or clamp to block the other end of the pipeline under test. In the present invention, the pressure transmitter power supply 6 converts 220V AC power into 24V DC power suitable for the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com