Method for detecting interlayer offset and drilling offset of multi-layer circuit board

A technology of offset detection and multi-layer circuit, which is applied in the direction of measuring devices and instruments, can solve the problems of inability to judge the offset of drilling holes and the inability to directly read the offset between layers, so as to save production time and reduce the risk of scrapping , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the embodiments.

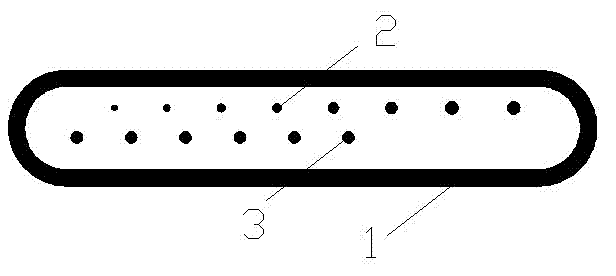

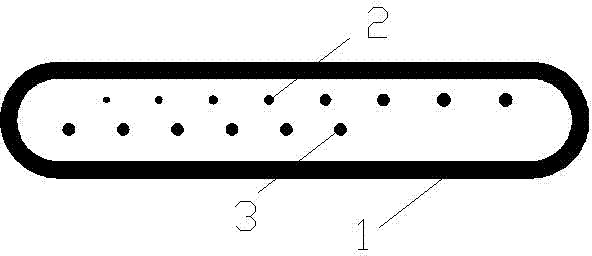

[0016] This embodiment adopts the technical solution of the present invention to realize accurate detection of interlayer and drilling offset of eight-layer circuit boards, including the following steps: The detection module is set at the corner of the board, such as figure 1 As shown, the detection module includes an isolation frame composed of two parallel copper strips and copper semi-circular rings connected at both ends of the two parallel copper strips. Measurement ring 2 and monitoring ring 3 for several level offsets.

[0017] The above-mentioned isolation frame is used to isolate the detection pattern to prevent the connection with other graphics from destroying the integrity of other graphics. The length of the two parallel copper strips of the isolation frame is 23.5MM and the width is 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com