Electrical switch

A technology for switches and electric loads, applied in the field of switches, can solve problems such as low elasticity, hard-to-contact chamber compression, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

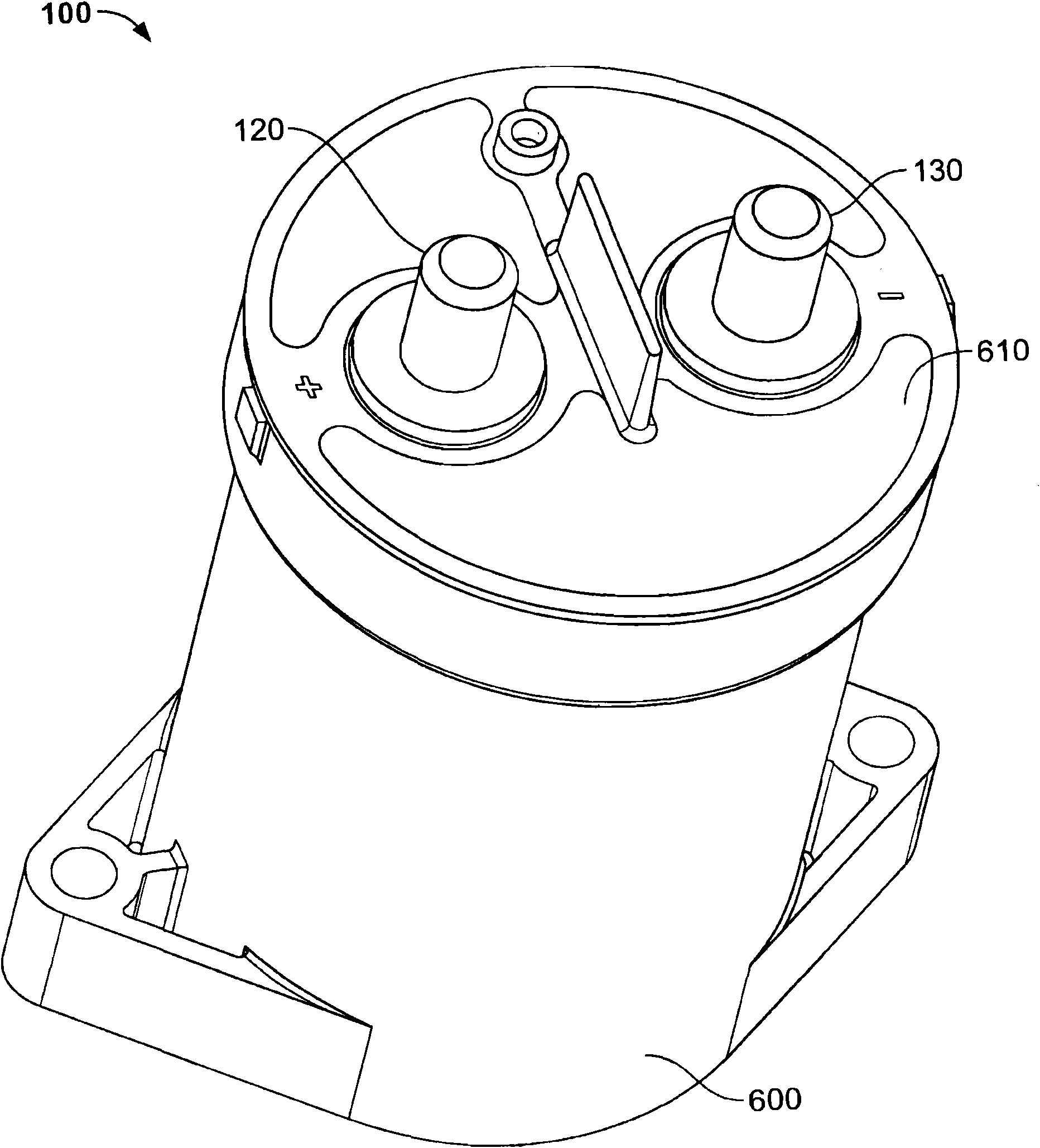

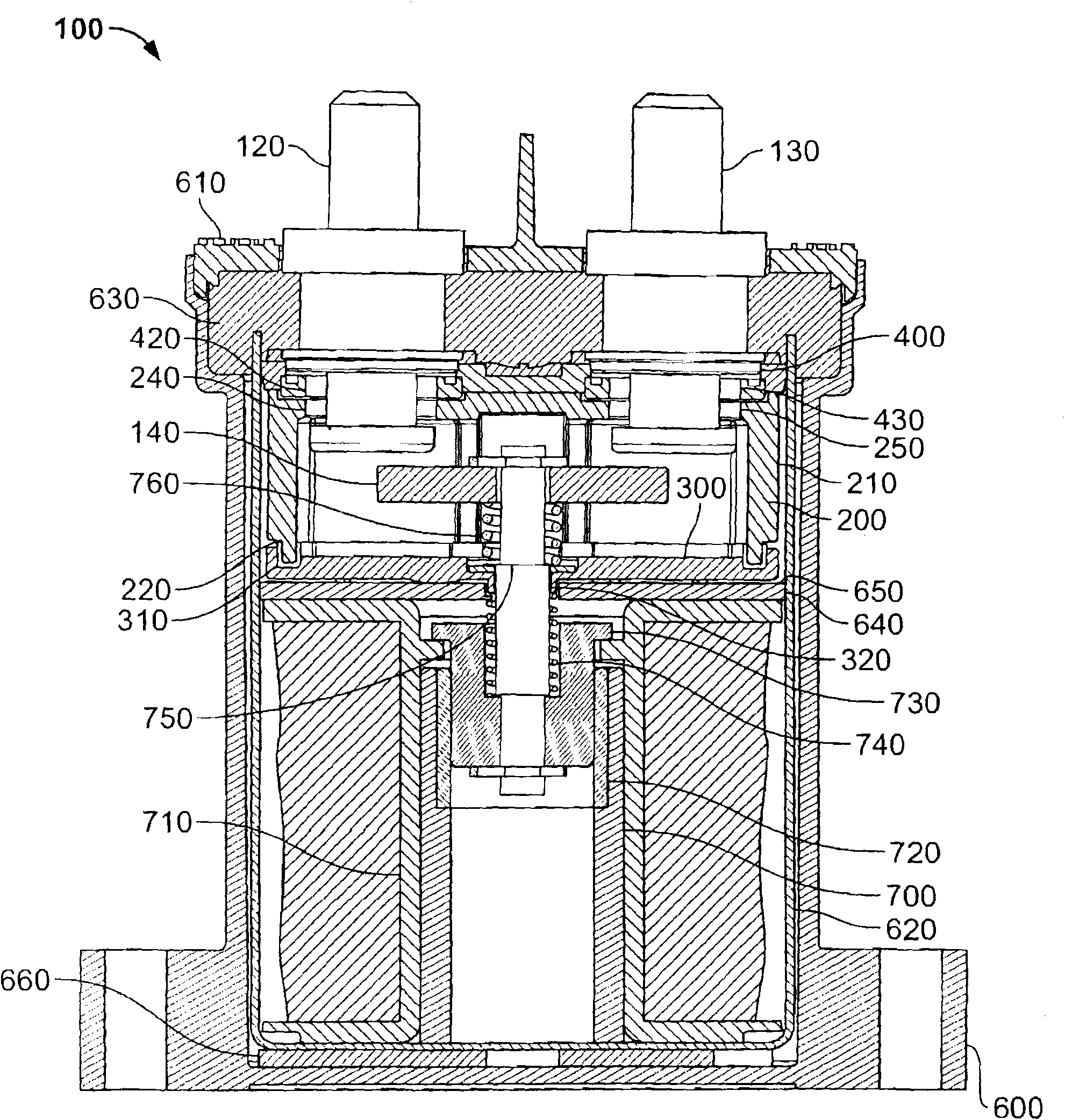

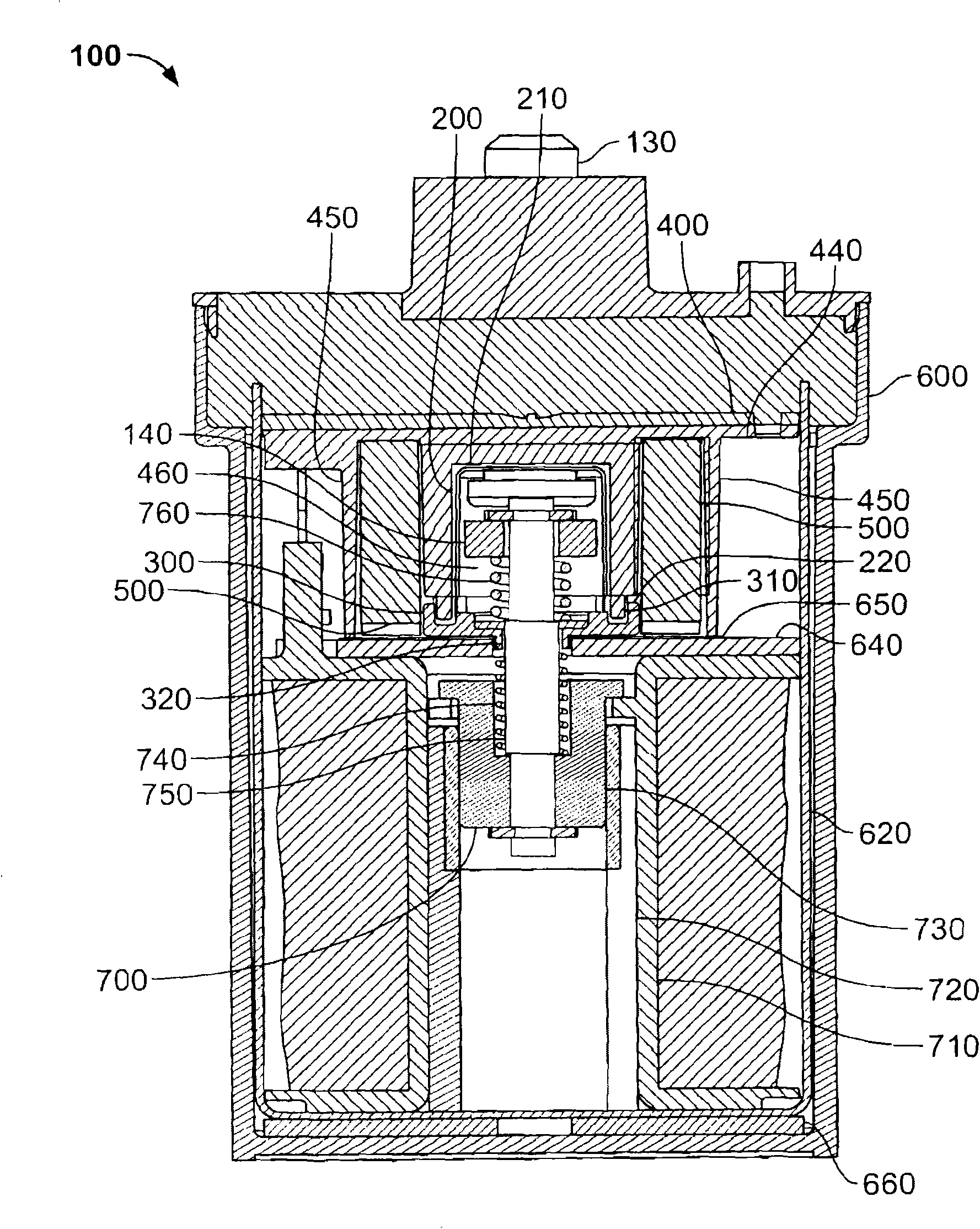

[0032] figure 1 is a perspective view of a switch 100 for switching electrical loads. The switch 100 may also be referred to as a relay or a contactor. The switch 100 includes a housing 600 having a dome 610 . Housing 600 and dome 610 may comprise a plastic material or another material.

[0033] The first contact member 120 and the second contact member 130 are guided through two apertures into the dome 610 . The first contact member 120 and the second contact member 130 comprise an electrically conductive material, such as metal, and are arranged as electrical contacts connected to an electrical load to be switched, such as an electric motor.

[0034] The switch 100 is provided to open and close the electrical connection between the first contact member 120 and the second contact member 130 . In this way, the switch 100 can be used, for example, to switch the power supply to a motor. When it is turned off, for example at a voltage exceeding 850V, a high current exceeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com