Charger structure

A charger and circuit board technology, applied in the direction of secondary battery charging/discharging, secondary battery repair/maintenance, etc., can solve the problem of limiting power supply or ground wiring line width, increasing the design difficulty of designers, electronic noise interference, etc. problems, to achieve the effect of shortening production man-hours, reducing design man-hours, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

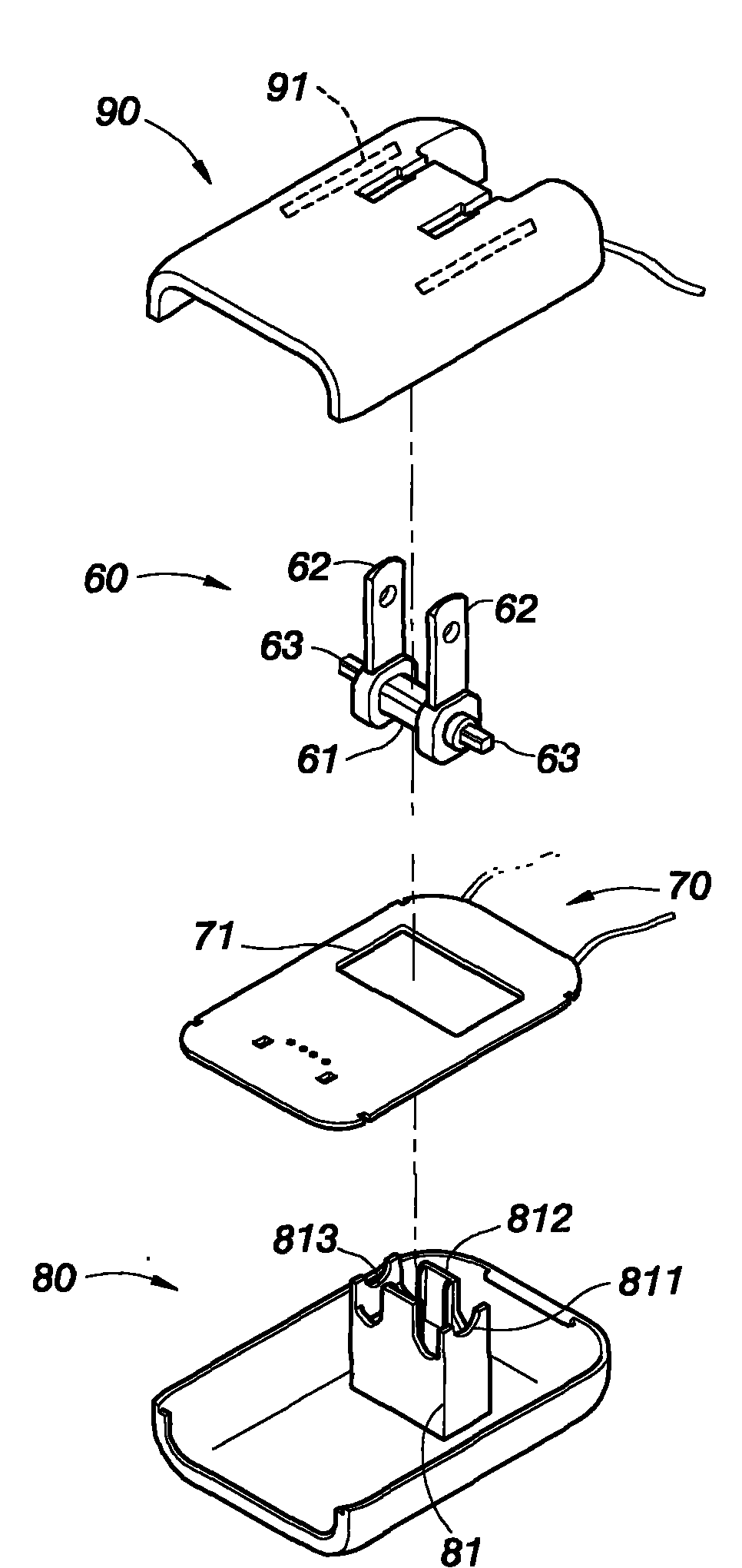

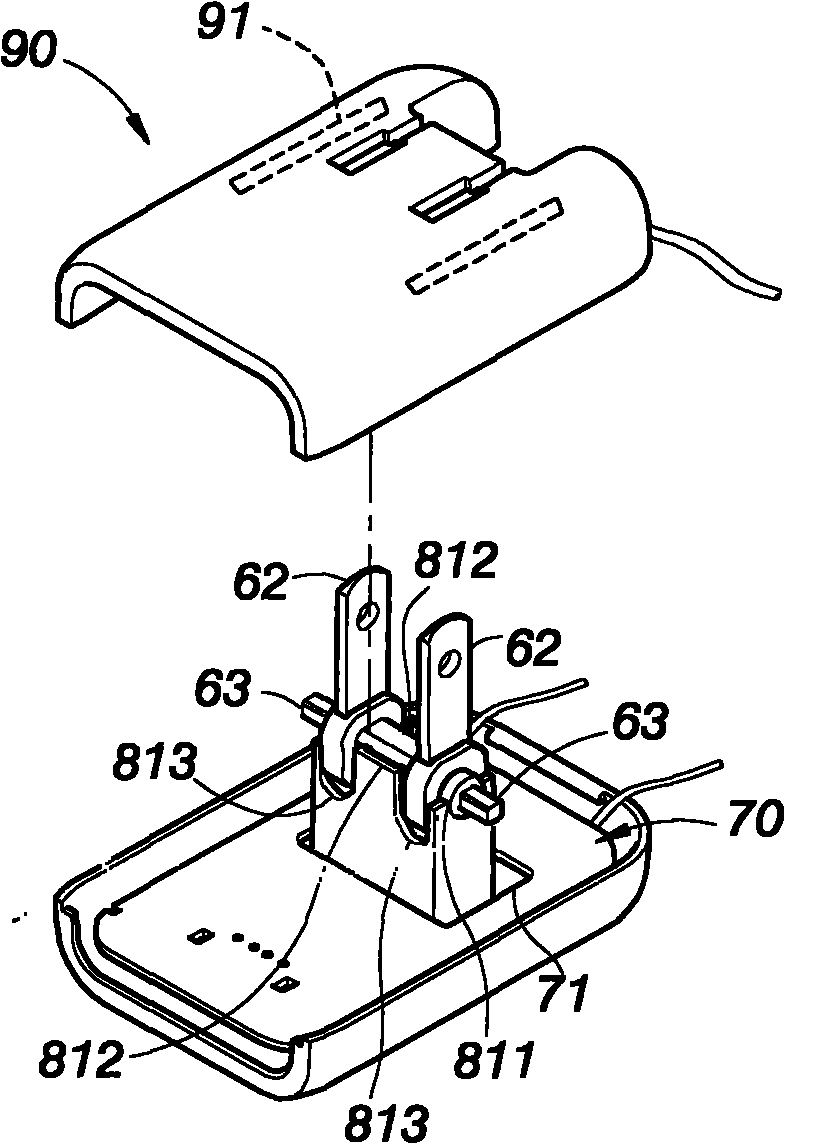

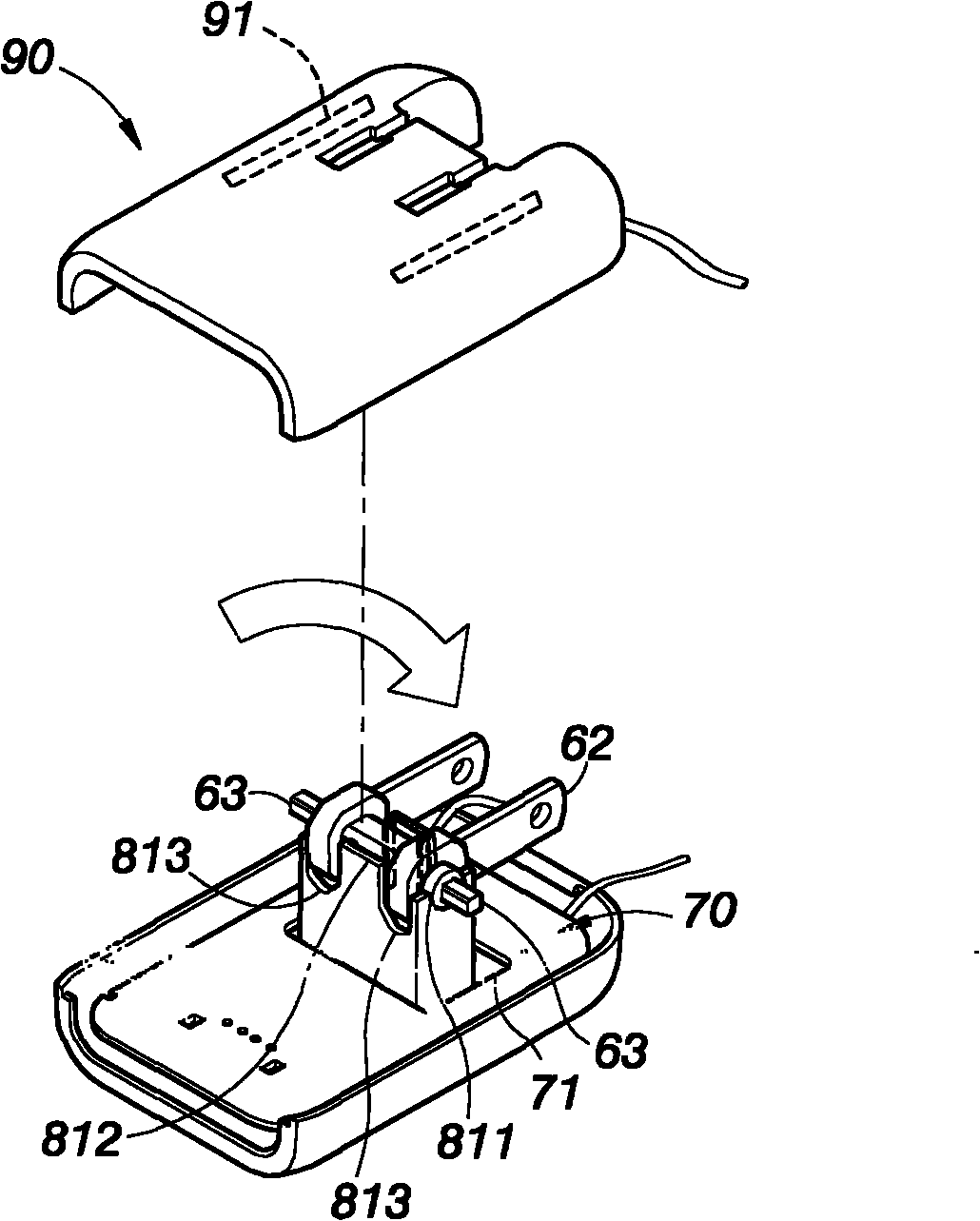

[0041] According to the technical means of the present invention, the specific embodiments suitable for the present invention are enumerated below, and are described in conjunction with the drawings as follows:

[0042] Such as Figure 4 , Figure 5 As shown, a "charger structure" of the present invention includes a first housing 10, a second housing 20, a circuit board 30 arranged between the first and second housings 10, 20, a positioning Cover plate 40, and a plug unit 50, wherein:

[0043] The first housing 10 is provided with a receiving plate 11, and the receiving plate 11 is provided with a positioning column 12 opposite to the second housing 20, and the positioning column 12 can be installed by the aforementioned positioning cover 40 It is inserted and positioned at the same time, and the storage plate 11 is provided with a storage space 13 that can accommodate the aforementioned plug unit 50 on the other side of the positioning column 12, and the first housing 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com