Solar cell panel busbar fixing mechanism

A technology for solar panels and fixing mechanisms, which is applied to contact parts, bases/housings, devices for joining/disconnecting connecting parts, etc. It can solve the problems of unreliable fixing, insufficient pressure, and easy heating, etc., and achieve improved electrical performance. performance, reduced resistance value, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

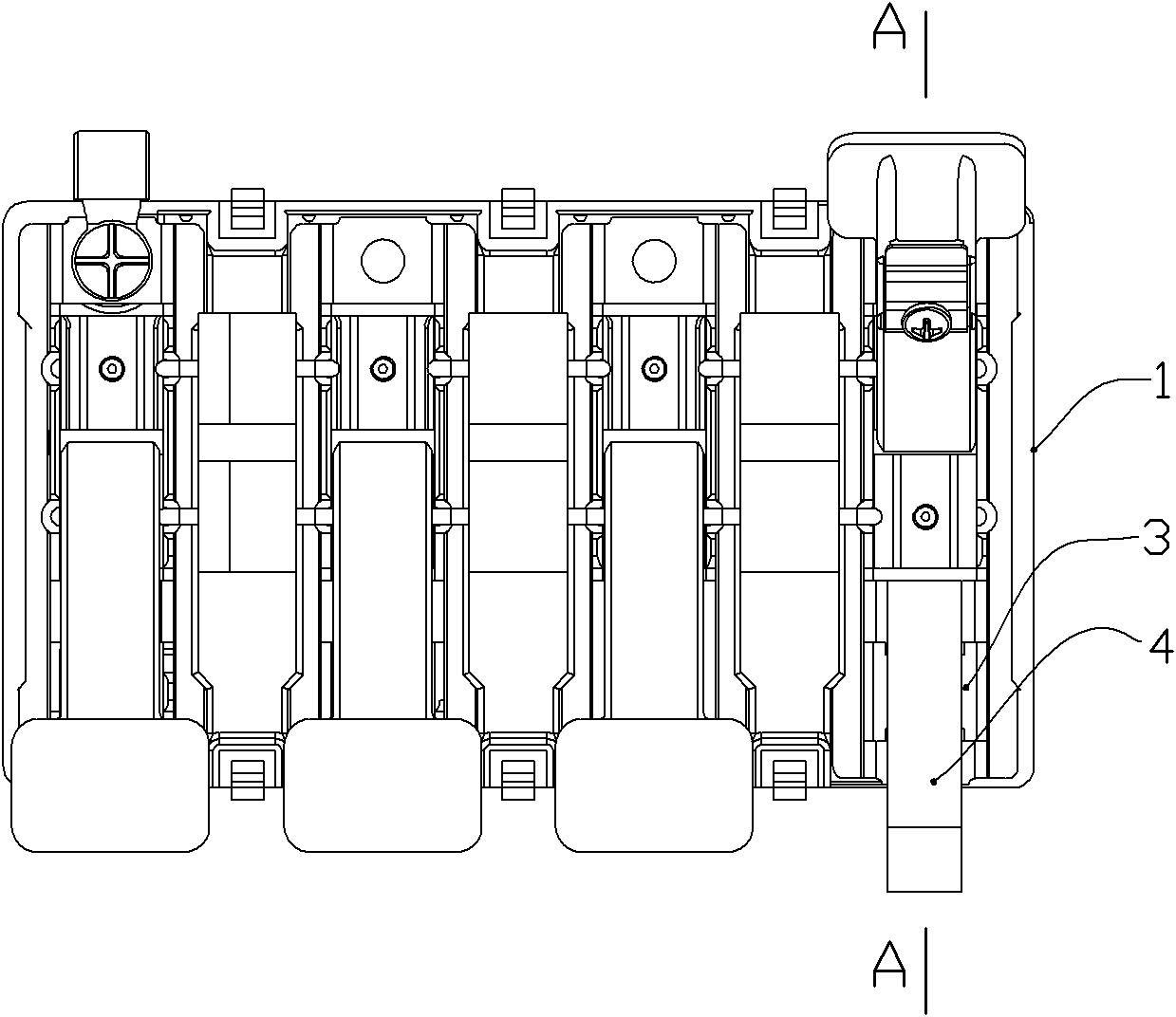

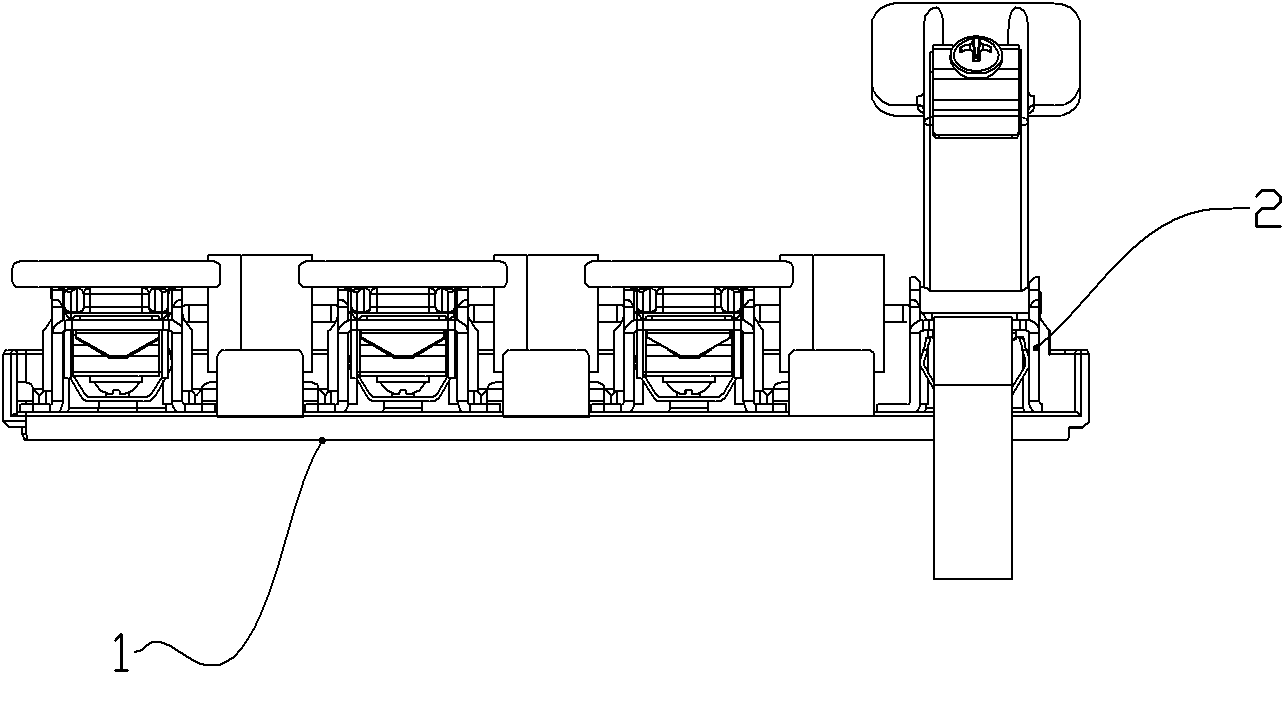

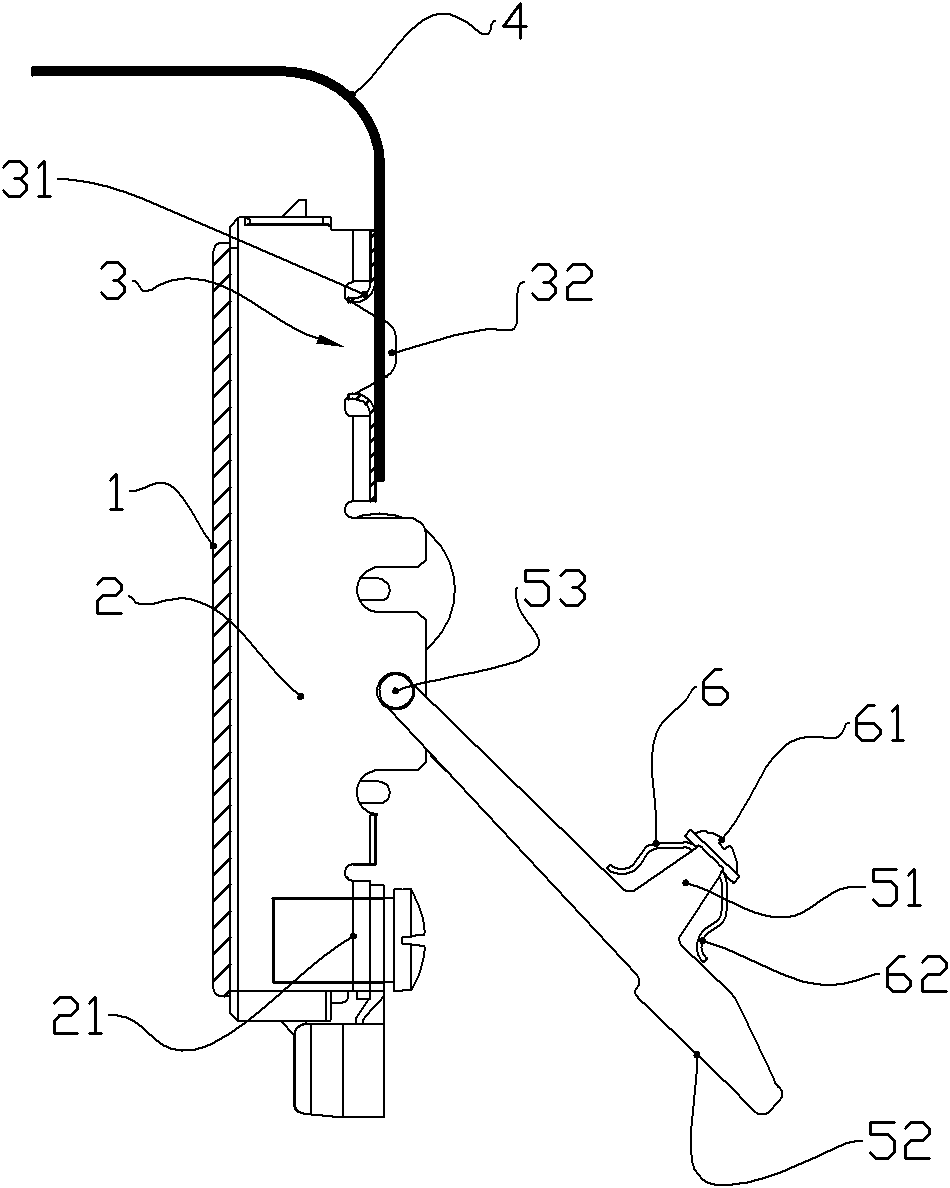

[0022] Such as Figure 1 to Figure 5 As shown in the solar cell panel bus bar fixing mechanism, the bus bar fixing mechanism presses and fixes the bus bar by buckling, and the buckling part of the bus bar bends during the buckling process, forming a knot shape, difficult to fall off.

[0023] Including positioning part and pressing part.

[0024] The positioning part includes a substrate 1 and busbars 2 mounted on the substrate, and there are four busbars in the figure. The base plate 1 is an insulating board and serves as a mounting platform for other components. The bus bar 2 is a box-shaped body upside down on the substrate 1, which is a sheet metal part. The front part of the bus bar 2 is a cable installation part 21, which is used to connect with the cables in the power grid; Different bus bars are connected; there is a rectangular opening 3 on the upper surface of the rear part, which is used to locate the bus bar 4, and the front and rear edges of the rectangular ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com