Terminal of battery connector

A battery connector and battery technology, applied in the direction of contact parts, etc., can solve the problems of current loss, resistance increase, etc., and achieve the effect of reducing energy consumption, reducing resistance value, and increasing effective contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

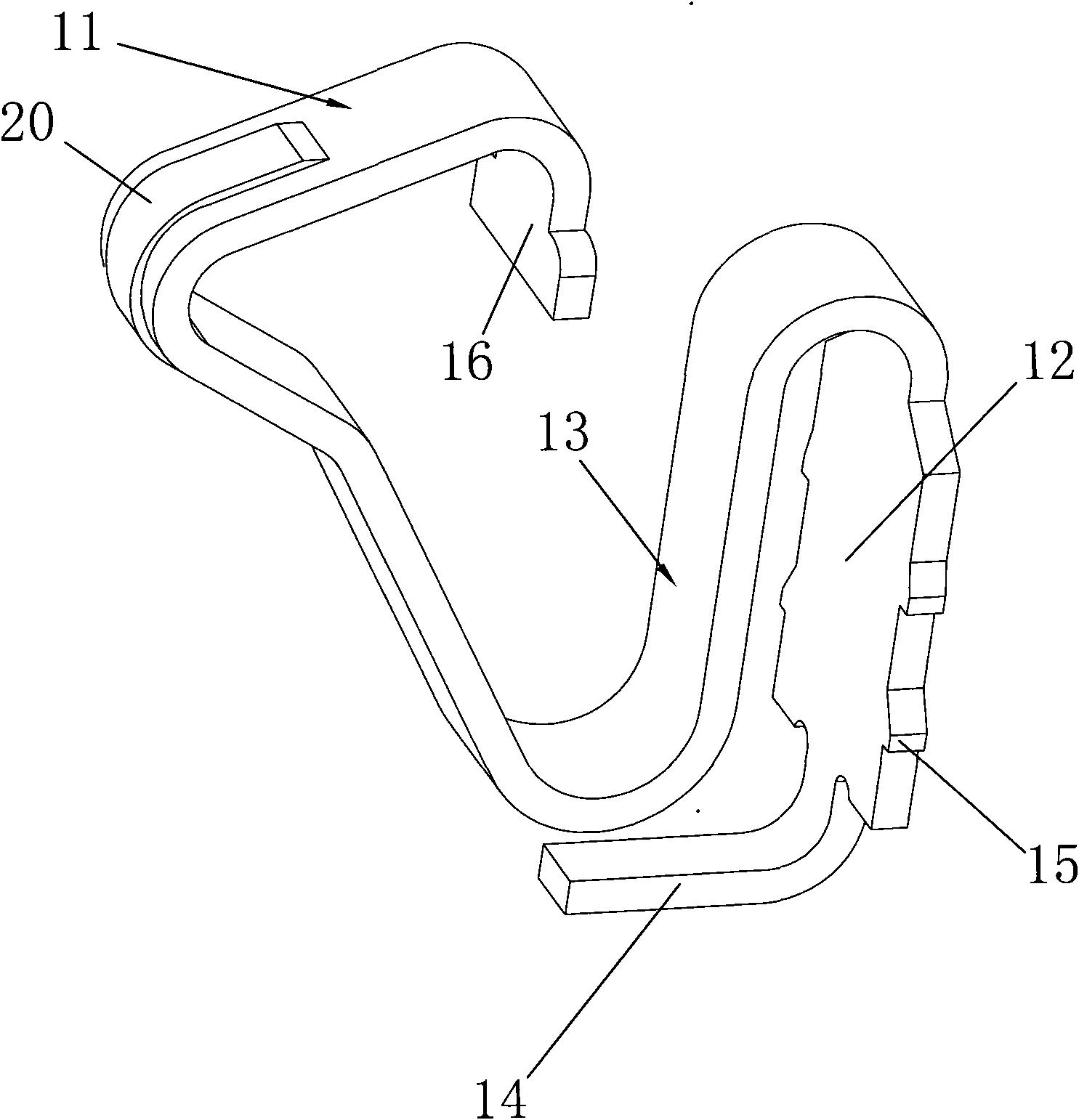

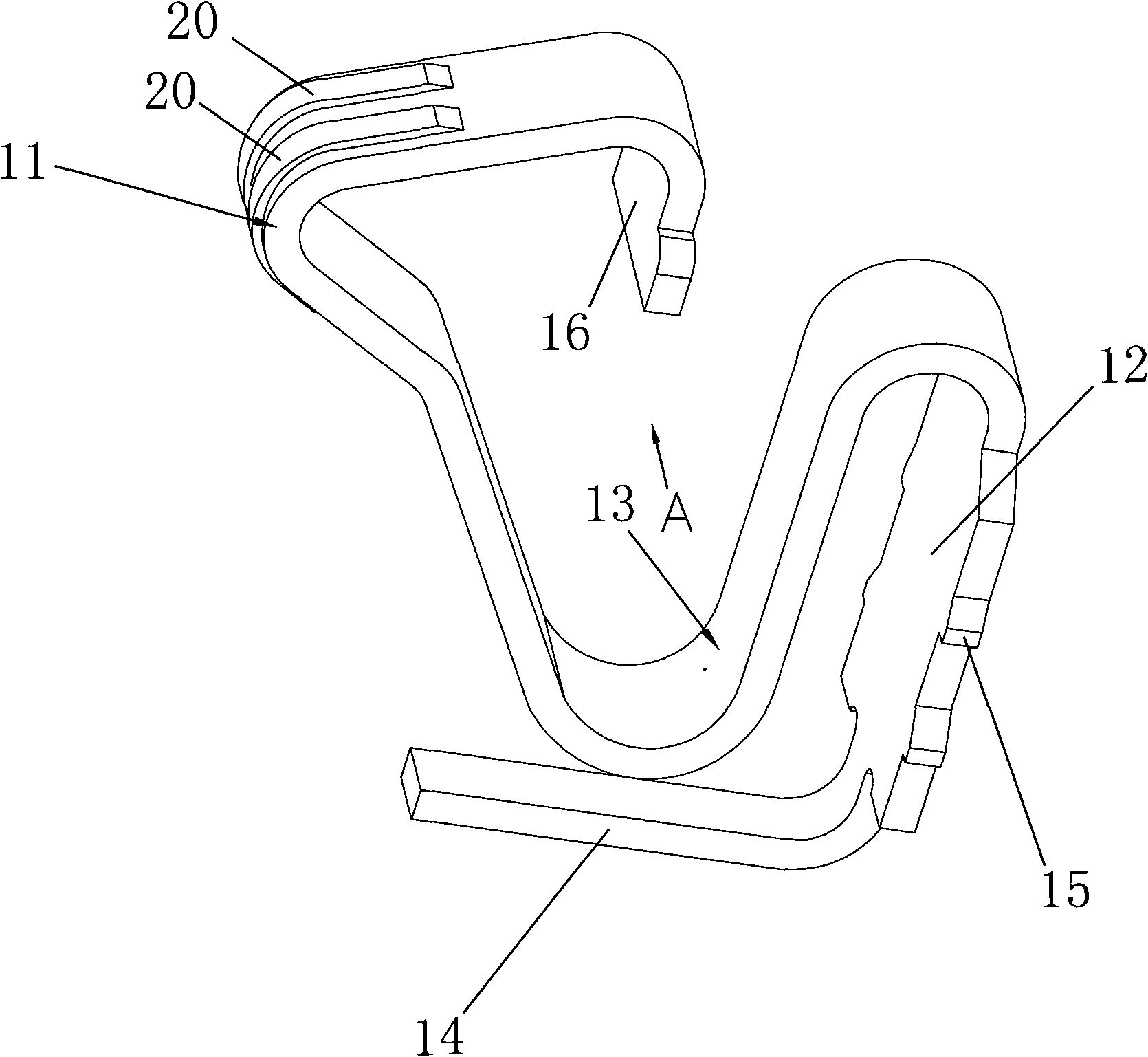

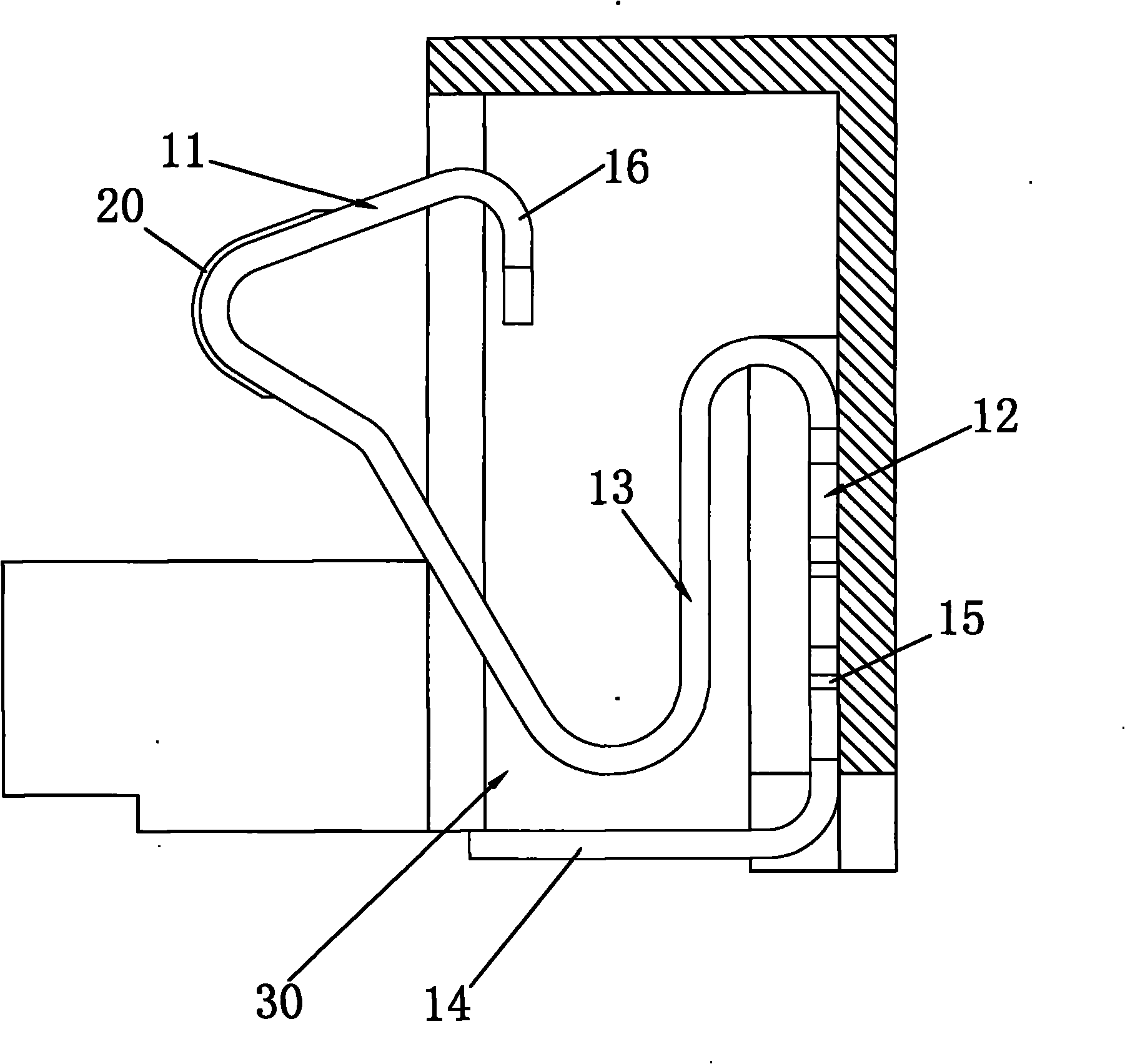

[0019] Embodiment: A battery connector terminal, which is integrally extended and bent in sequence to form a stop part 16, a battery contact part 11, a connecting part 13, a fixing part 12 and a welding part 14, and the surface of the battery contact part 11 protrudes at intervals There are at least two ribs 20, which not only increases the effective contact surface between the battery and the battery contact part 11 in use, but also reduces the resistance value compared with the original structure, and the strength of the current passing through the battery contact surface 11 will increase , reducing energy consumption.

[0020] Two ribs 20 protrude from the surface of the battery contact portion 11 at intervals.

[0021] The two ribs 20 are respectively close to the two sides of the battery contact portion 11, and the two ribs 20 are parallel to the sides of the battery contact portion 11, the battery will inevitably vibrate during use, and the two parallel ribs 20 can Effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com