A kind of anti-slip rubber product, its preparation method and its application

A rubber product and anti-slip technology, applied in the field of rubber, can solve the problems of unfavorable promotion and use, high cost, high cost of special rubber, etc., and achieve the effects of promoting the use of large areas, increasing friction, and good cost advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

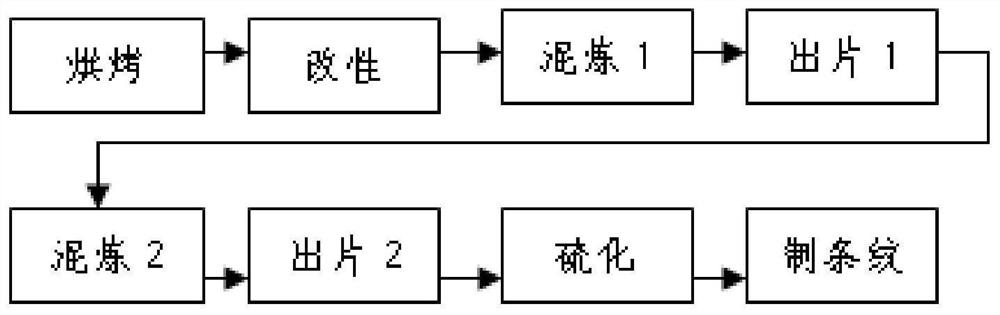

[0050] figure 1 It is a schematic diagram of the process flow for preparing anti-slip rubber products in the embodiment of the present invention; the embodiment of the present invention provides the preparation method of the anti-slip rubber products as described above, comprising the following steps:

[0051] According to the number of parts by mass, the base rubber, fiber and coupling agent are mixed and then preliminarily mixed to obtain a mixed rubber compound;

[0052] Mixing the mixed rubber material, active agent and softening oil, kneading again, and then adding an accelerator and a crosslinking agent to vulcanize to obtain a rubber product;

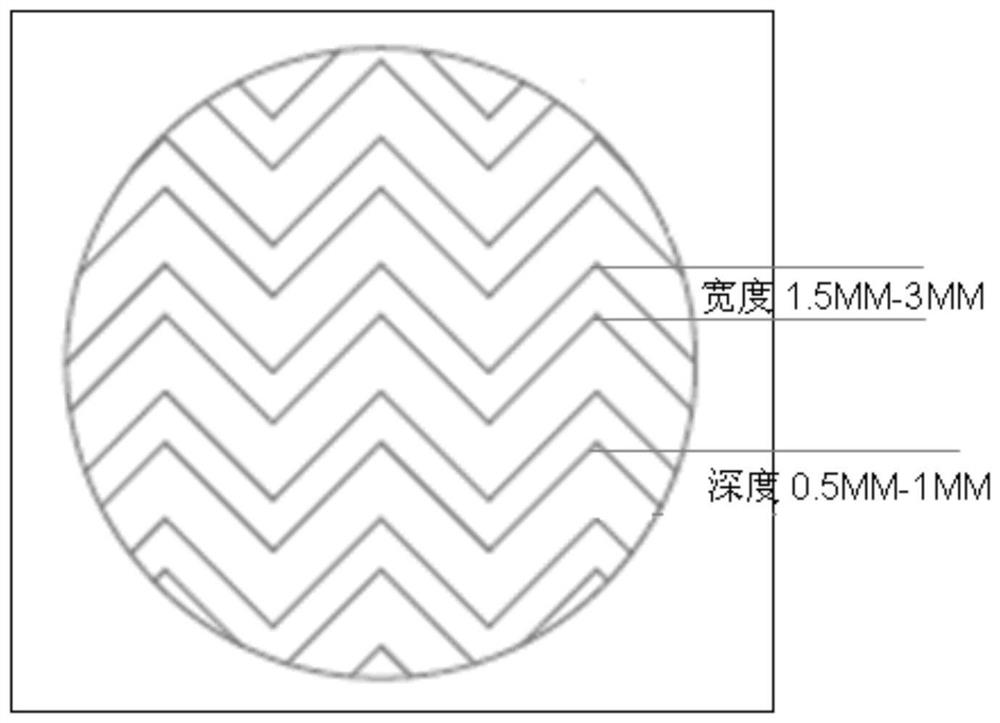

[0053] The surface of the rubber product is peeled to form stripes to obtain a non-slip rubber product with zigzag linear stripes.

[0054] see figure 1 In the embodiment of the present invention, the fiber is preferably baked until the moisture content is less than 0.1%. Specifically, the temperature of the oven can be adjuste...

Embodiment 1

[0070] see figure 1 , according to the following steps to prepare anti-slip rubber products; and, the material formula of this embodiment is shown in Table 1.

[0071] Baking: Adjust the oven temperature to 80°C, then put the alkali-free glass fiber powder (13-18μm in diameter, 10-30 mesh) into the oven, bake for 2 hours, and dry the moisture on the surface of the fiber powder , The moisture content of fiber powder is less than 0.1%.

[0072] Modification: Pour the baked fiber powder into the high-speed mixing tank, then pour in the silane coupling agent in specified parts by mass, adjust the speed of the high-speed mixing tank to 1000 rpm, and stir for 3 minutes to make the silane coupling The agent is fully mixed with the fiber powder to modify the fiber powder into organophilicity.

[0073] Mixing 1: Pour the base rubber into the internal mixer, then pour the mixture of silane coupling agent and fiber powder into the internal mixer, start the internal mixer, and mix for 8...

Embodiment 2~3

[0083] Based on the implementation steps of Example 1, adjust the formula according to Table 1, and prepare corresponding anti-slip rubber products; wherein, the stripes on the surface of the finished product are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com