Commercial bright-spot rubber-plastic floor and preparation method thereof

A bright spot and flooring technology, applied in coatings, buildings, fireproof coatings, etc., to achieve strong anti-slip, good elasticity, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

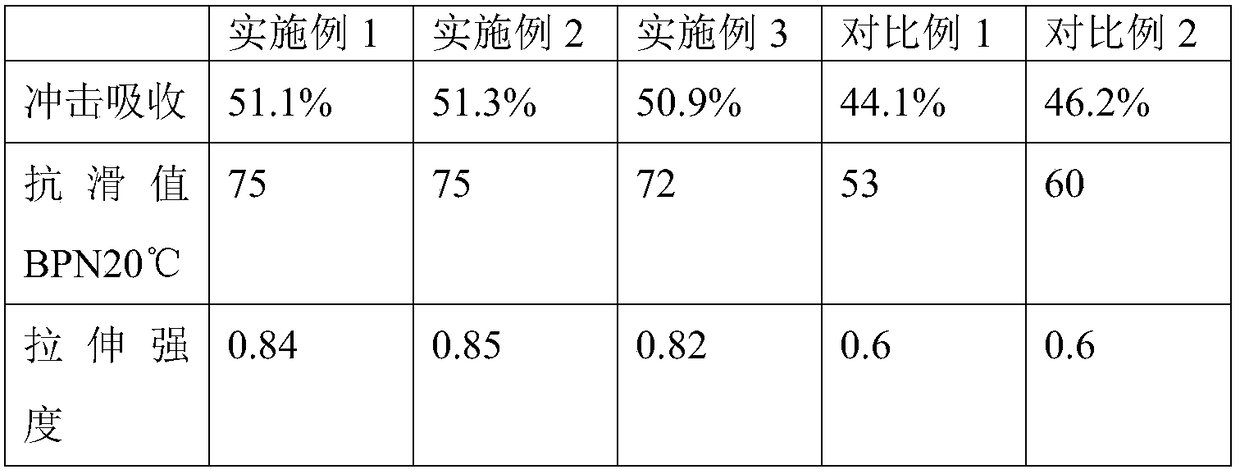

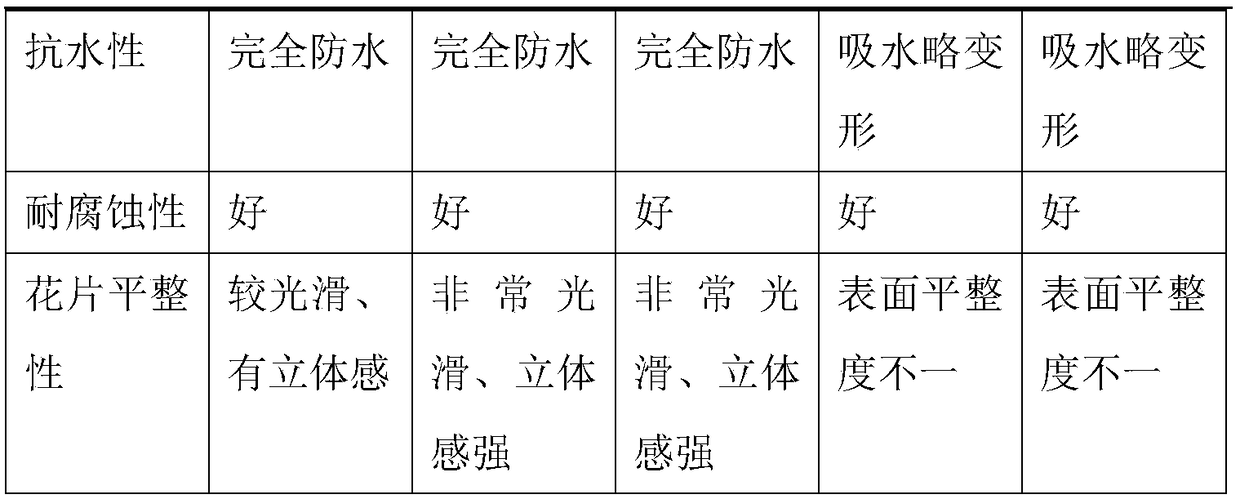

Examples

Embodiment 1

[0041] According to the formula of commercial highlight rubber and plastic flooring, it contains 100 parts by weight of paste polyvinyl chloride resin, 36 parts of synthetic vegetable ester, 9 parts of DPHP, 1 part of zinc stearate, 1 part of calcium stearate, 0.5 parts of hydrotalcite, and 0.5 parts of paraffin wax. Parts, 1 part by weight of 2-hydroxyl-4-n-octyloxybenzophenone, 0.5 parts by weight of light stabilizer HS-944, 0.5 parts by weight of light stabilizer HA22, 3-iodo-2-propynylbutylcarbamate 1 part by weight of ester, 0.75 part by weight of octyloxysilane, 0.25 part by weight of sodium methyl silicate, and 3 parts by weight of calcium carbonate were prepared according to the multiple scraping method of this application.

[0042] Example 1

[0043] According to the formula of commercial highlight rubber and plastic flooring, it contains 100 parts by weight of paste polyvinyl chloride resin, 36 parts of synthetic vegetable ester, 9 parts of DPHP, 1 part of zinc stear...

Embodiment 2

[0045] According to the formula of commercial highlight rubber and plastic flooring, it contains 100 parts by weight of paste polyvinyl chloride resin, 36 parts of synthetic vegetable ester, 9 parts of DPHP, 1 part of zinc stearate, 1 part of calcium stearate, 0.5 parts of hydrotalcite, and 0.5 parts of paraffin wax. Parts, 1 part by weight of 2-hydroxyl-4-n-octyloxybenzophenone, 0.5 parts by weight of light stabilizer HS-944, 0.5 parts by weight of light stabilizer HA22, 3-iodo-2-propynylbutylcarbamate 1 part by weight of ester, 0.75 part by weight of octyloxysilane, 0.25 part by weight of sodium methyl silicate, and 3 parts by weight of calcium carbonate were prepared according to the multiple scraping method of this application.

Embodiment 3

[0047] According to the formula of commercial highlight rubber and plastic flooring, it contains 100 parts by weight of paste polyvinyl chloride resin, 36 parts of synthetic vegetable ester, 9 parts of DPHP, 1 part of zinc stearate, 1 part of calcium stearate, 0.5 parts of hydrotalcite, and 0.5 parts of paraffin wax. Parts, 1 part by weight of 2-hydroxyl-4-n-octyloxybenzophenone, 0.5 parts by weight of light stabilizer HS-944, 0.5 parts by weight of light stabilizer HA22, 3-iodo-2-propynylbutylcarbamate 0.5 parts by weight of ester, 0.5 parts by weight of propiconazole, 0.75 parts by weight of octyloxysilane, 0.25 parts by weight of sodium methyl silicate, and 3 parts by weight of calcium carbonate were prepared according to the method of multiple scraping in this application.

[0048] Example 3

[0049] According to the formula of commercial highlight rubber and plastic flooring, it contains 100 parts by weight of paste polyvinyl chloride resin, 36 parts of synthetic vegetabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com