Anti-slip thermoplastic polyurethane composite material and preparation method thereof

A technology of thermoplastic polyurethane and composite materials, applied in the field of thermoplastic polyurethane composite materials, can solve the problems of poor anti-slip performance, easy slipping and wrestling, etc., achieve scientific and reasonable formula, simple and practical process, and improve the effect of anti-slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

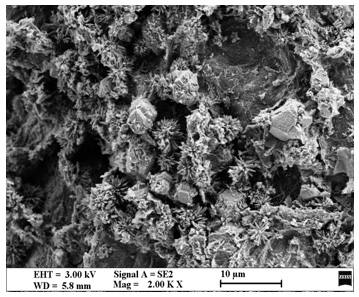

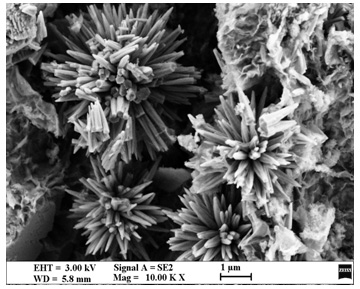

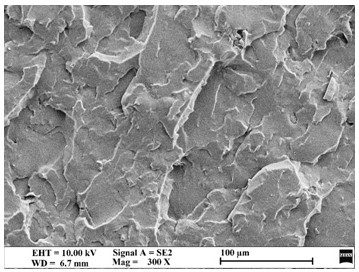

Image

Examples

Embodiment 1

[0027] A preparation method of an anti-slip thermoplastic polyurethane composite material, the specific steps are:

[0028] 1) Preparation of graphene oxide: Dissolve 1g of graphite in 40mL of concentrated sulfuric acid, place it in a magnetic stirrer and stir evenly, slowly add 4g of potassium permanganate weighed in small amounts within 3 hours; heat to 35°C Continue to stir for 2 hours, slowly add 80ml of deionized water dropwise and then raise the temperature to 90°C, slowly add hydrogen peroxide solution dropwise and observe that there are no bubbles, stop the dropwise addition, then add 20ml of 5wt% hydrochloric acid and stir for a period of time, and the reaction ends; use deionized water After washing, centrifuging, and freeze-drying, graphene oxide is obtained;

[0029] 2) Preparation of graphene-based nanocomposite (RGO-HCA): add the graphene oxide (GO) prepared in step 1) into 100ml of sodium hydroxide solution with PH=11 and sonicate for 0.5h, and use a magnetic st...

Embodiment 2

[0036] A preparation method of an anti-slip thermoplastic polyurethane composite material, the specific steps are:

[0037] 1) Preparation of graphene oxide: Dissolve 1g of graphite in 40mL of concentrated sulfuric acid, place it in a magnetic stirrer and stir evenly, slowly add 4g of potassium permanganate weighed in small amounts within 3 hours; heat to 35°C Continue to stir for 2 hours, slowly add 80ml of deionized water dropwise and then raise the temperature to 90°C, slowly add hydrogen peroxide solution dropwise and observe that there are no bubbles, stop the dropwise addition, then add 20ml of 5wt% hydrochloric acid and stir for a period of time, and the reaction ends; use deionized water After washing, centrifuging, and freeze-drying, graphene oxide is obtained;

[0038] 2) Preparation of graphene-based nanocomposite (RGO-HCA): add the graphene oxide (GO) prepared in step 1) into 100ml of sodium hydroxide solution with PH=11 and sonicate for 0.5h, and use a magnetic stir...

Embodiment 3

[0045] A preparation method of an anti-slip thermoplastic polyurethane composite material, the specific steps are:

[0046] 1) Preparation of graphene oxide: Dissolve 1g of graphite in 40mL of concentrated sulfuric acid, place it in a magnetic stirrer and stir evenly, slowly add 4g of potassium permanganate weighed in small amounts within 3 hours; heat to 35°C Continue to stir for 2 hours, slowly add 80ml of deionized water dropwise and then raise the temperature to 90°C, slowly add hydrogen peroxide solution dropwise and observe that there are no bubbles, stop the dropwise addition, then add 20ml of 5wt% hydrochloric acid and stir for a period of time, and the reaction ends; use deionized water After washing, centrifuging, and freeze-drying, graphene oxide is obtained;

[0047] 2) Preparation of graphene-based nanocomposite (RGO-HCA): add the graphene oxide (GO) prepared in step 1) into 100ml of sodium hydroxide solution with PH=11 and sonicate for 0.5h, and use a magnetic st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com