Dip angle bearing universal coupling

A coupling and bearing technology, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of reducing transmission accuracy and efficiency, lack of positioning of the fixed axis, and unbalanced force on the balls. The effect of transmission accuracy and efficiency, force balance, and bearing capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

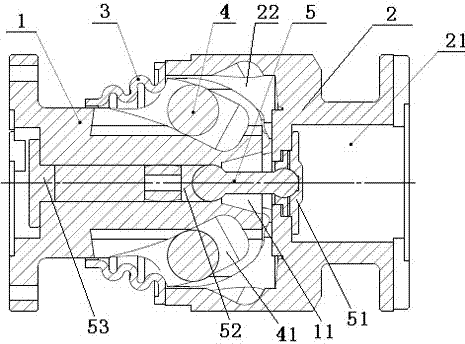

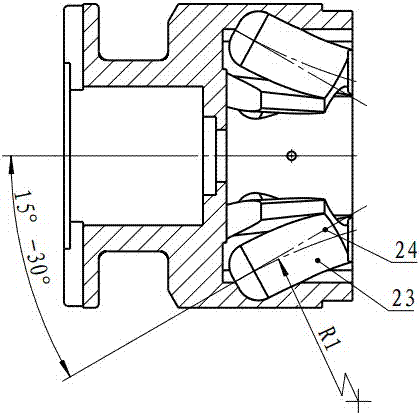

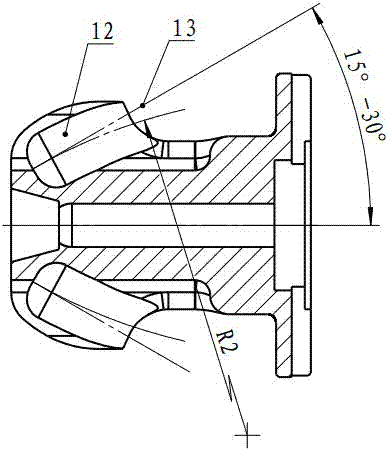

[0019] Such as figure 1 As shown, the present invention includes an inner ring 2, an outer ring 1, a centering device 5, and a sealing cover 3. One end of the inner ring is provided with a groove 22, and one end of the outer ring 1 is provided with a ball head. The head fits in the groove 22. The sealing cover 3 is sleeved on the outer ring 1 and connected with the opening end of the groove 22 of the inner ring 2 . The ball head and the side walls of the groove 22 are correspondingly provided with a plurality of arc-shaped grooves 12, 23, and the corresponding arc-shaped grooves on the side walls of the ball head and the groove form a plurality of cylindrical raceways 41, The center line of the cylindrical raceway 41 is an arc curve, and the ball 4 is arranged in the raceway 41 .

[0020] The center of one end of the inner ring 2 facing away from the groove 22 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com