Polyamide moulded masses containing semi-crystalline transparent copolyamides for producing highly flexible transparent moulded parts with high notch-impact strength, low water absorbency and excellent resistance to chemicals

A technology for notched impact strength, polyamide molding, applied in the field of flexible polyamide molding materials, which can solve the risk of component separation and the problems of quality transparency, color and purity decline, and difficult polyamide processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] The polyamide molding material according to the invention was produced in a known laboratory autoclave with a capacity of 130 1. First, a pressure phase is carried out at 290°C. Then the pressure was reduced at 280°C. Devolatilization was also carried out at 280°C. Subsequently, the strand-shaped polyamide molding material was discharged, cooled in a water bath, and pelletized. The granules were dried at 80 °C for 12 h to a water content below 0.06%. Highly transparent moldings or test pieces prepared from the transparent polyamide molding materials according to the invention were carried out on an Arburg 420C Allrounder 1000-250 injection molding machine at a melting temperature of 250°C to 280°C, with the mold temperature set to 60°C. The screw speed was 150 to 400 rpm.

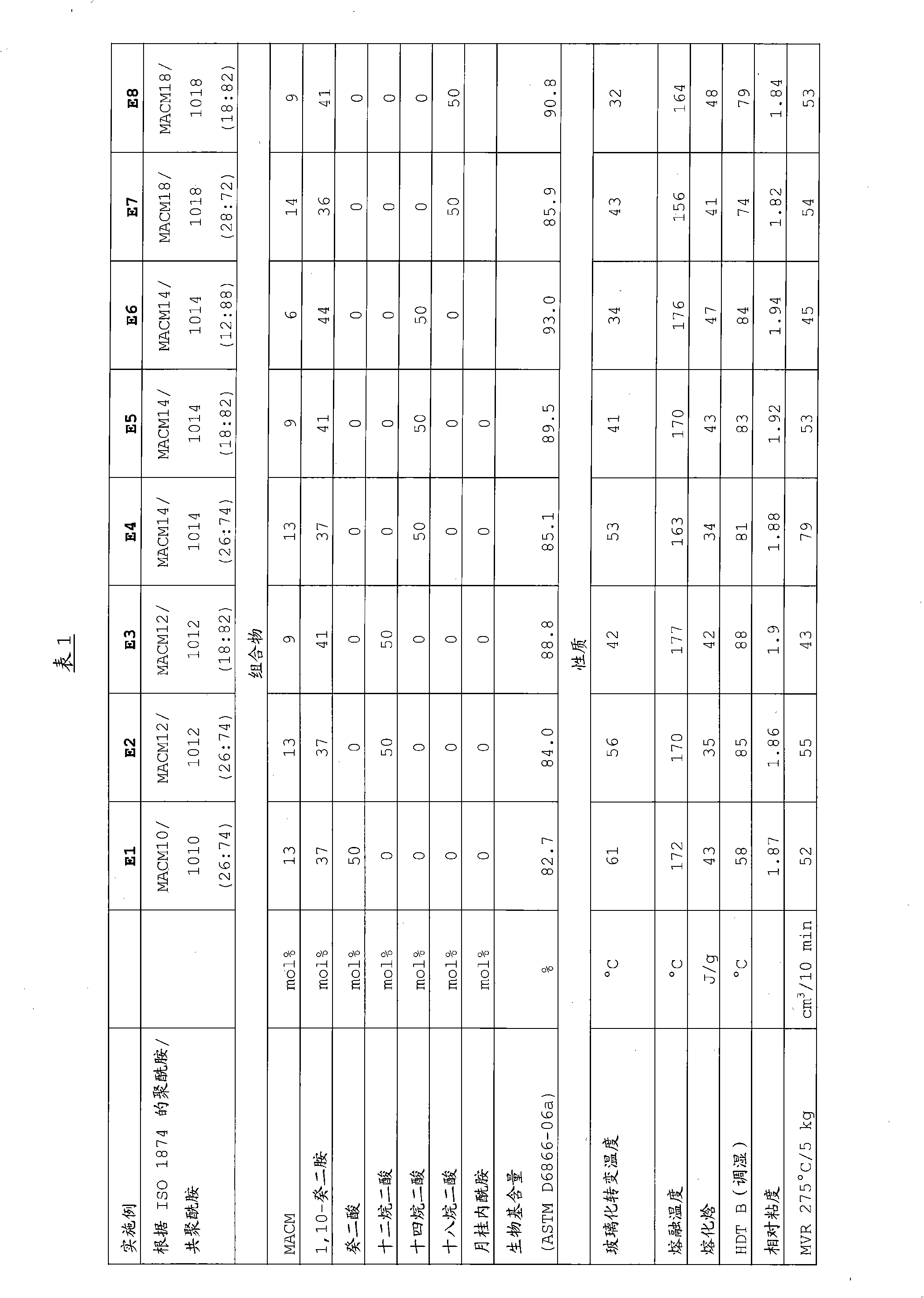

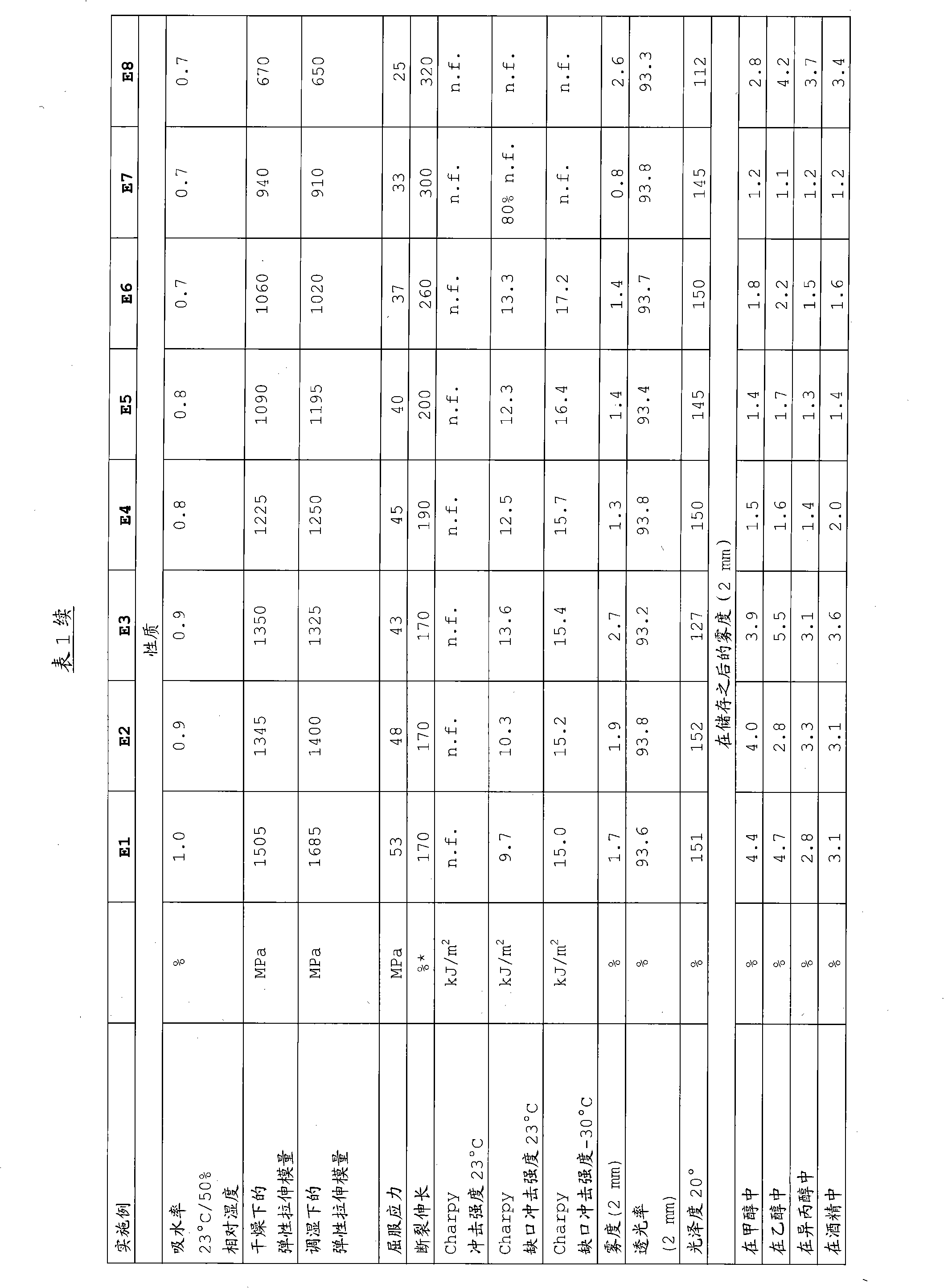

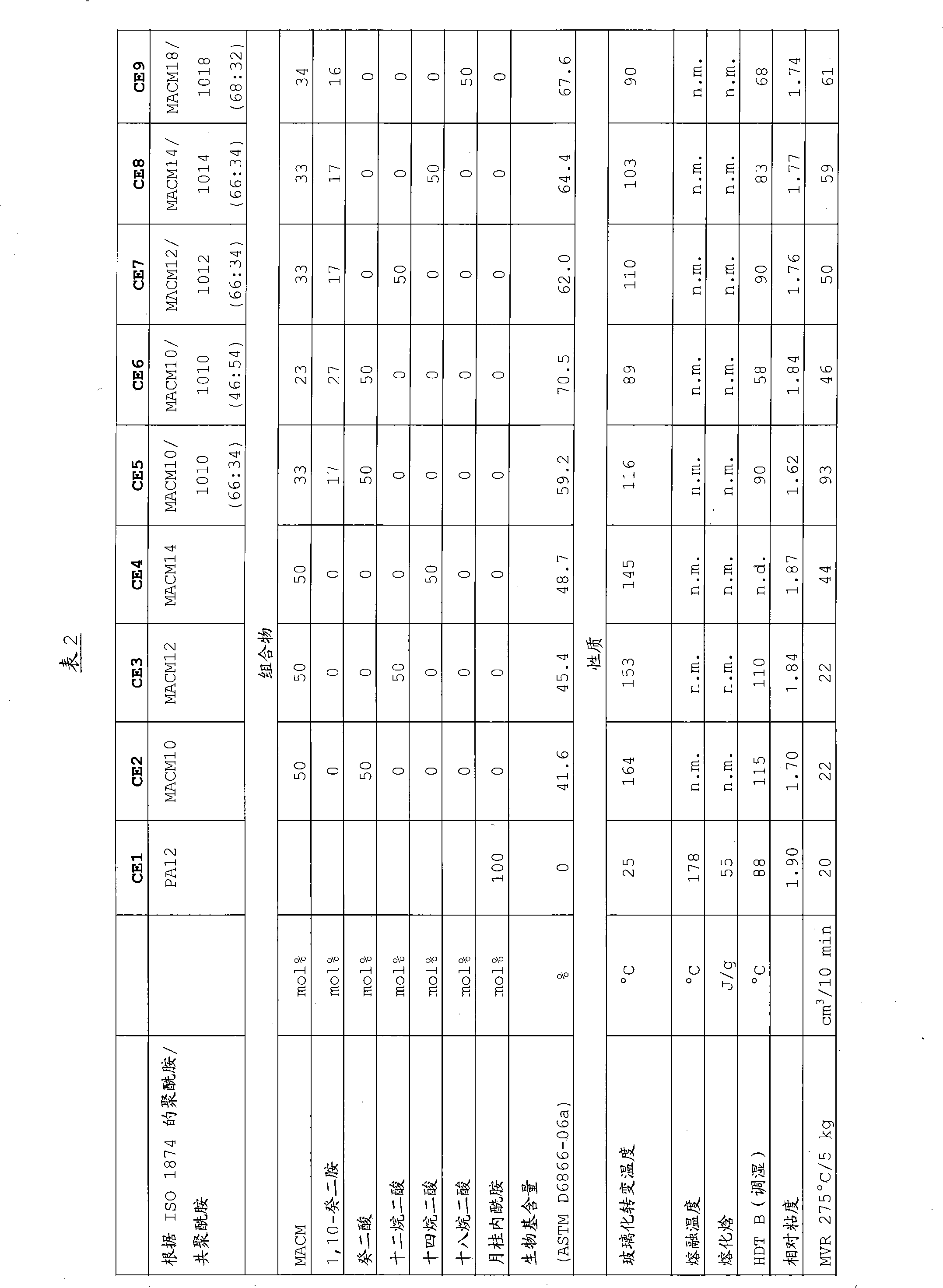

[0120] The resulting materials or moldings have the characteristic data listed in Tables 1 and 2.

[0121] In tables 1 and 2:

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com