Vacuum switching tube

A vacuum switching tube and steam technology, applied in the direction of electric switches, high voltage/high current switches, high voltage air circuit breakers, etc., can solve the problems of large structure shape, inconvenient use, expensive manufacture, etc., to improve the compressive strength, facilitate Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

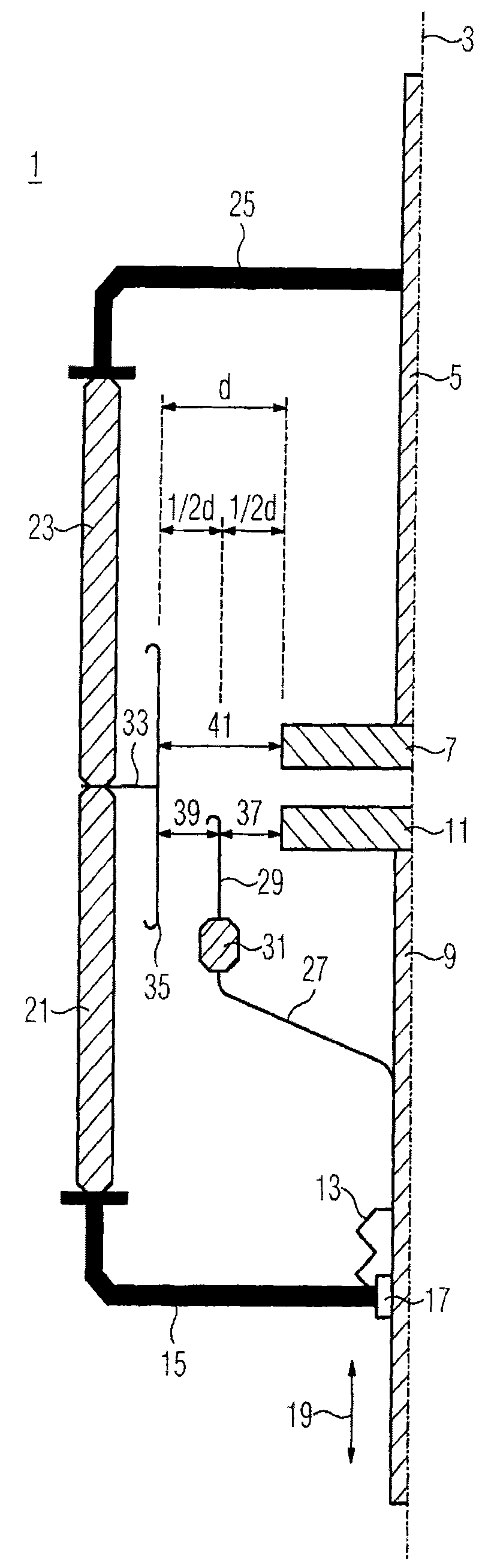

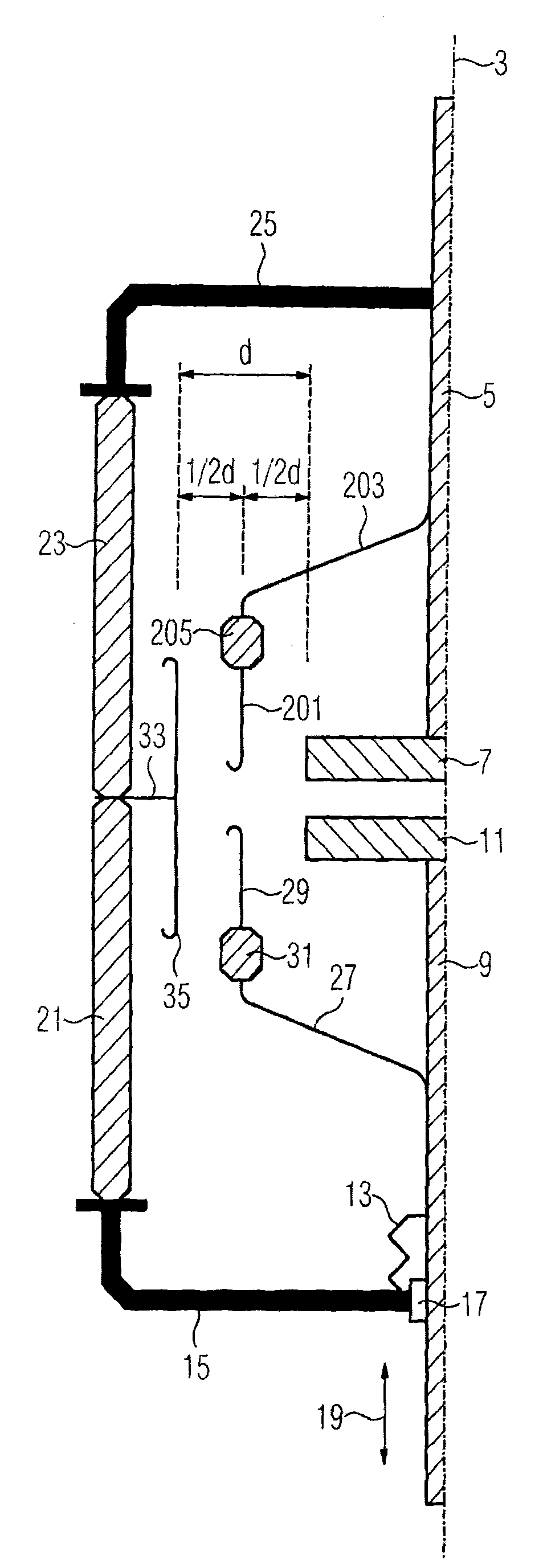

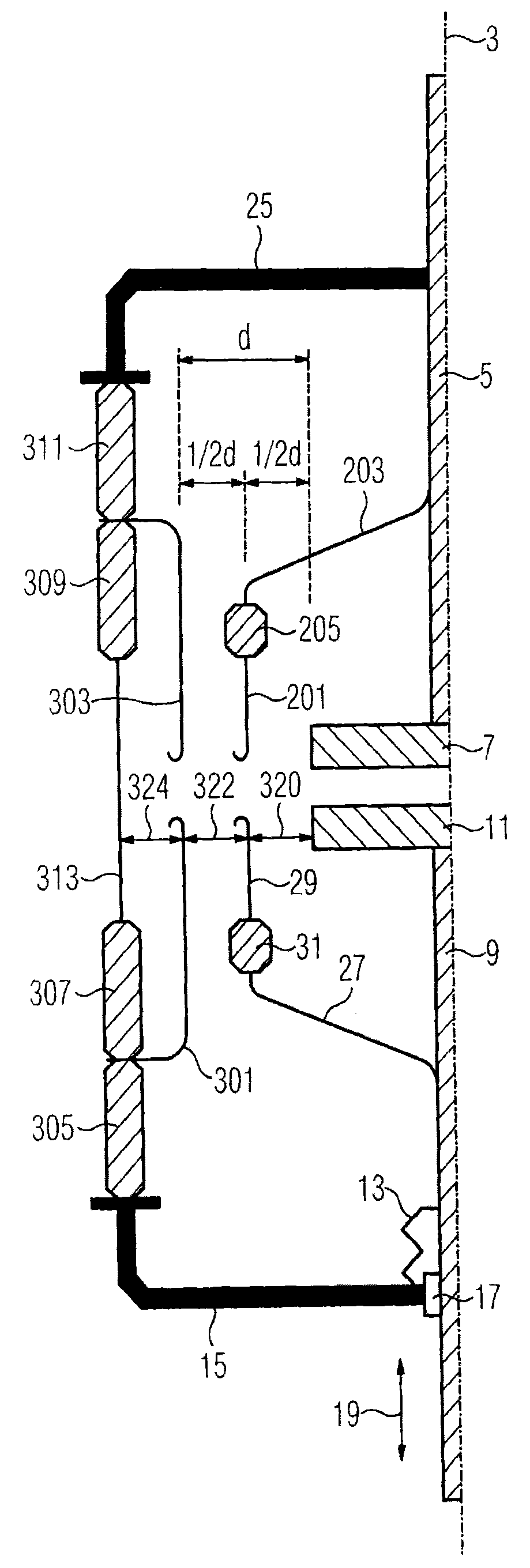

[0025] exist figure 1 A sectional view of an embodiment of a vacuum interrupter 1 envisaged according to the invention is shown in . Only one half of the vacuum interrupter is shown here in a sectional view, the other half being designed symmetrically with respect to the axis of symmetry or the axis of rotation 3 . The vacuum interrupter 1 has a fixed or stationary stem 5 which carries a first (static) contact 7 . A second (moving) contact 11 is fastened on the axially movable stem 9 . The axially displaceable stem 9 is connected to the metal cover 15 in an axially displaceable and vacuum-tight manner by means of an elastic bellows 13 . Such a metal cover 15 has a slide bearing 17 in which the axially displaceable stem 9 is guided. The axial movement that the moving contact rod 9 can carry out is represented by a double-headed arrow 19 .

[0026] The metal cover 15 is connected to a first insulating member 21 which has a hollow cylindrical shape and is composed of ceramics...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com