Light emitting element driving circuit

A technology for light-emitting components and driving circuits, applied in circuits, electrical components, electroluminescent light sources, etc., can solve problems such as brightness deviation and LED characteristic deviation, and achieve the effects of reducing current stress, prolonging life, and preventing overcurrent from flowing through.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

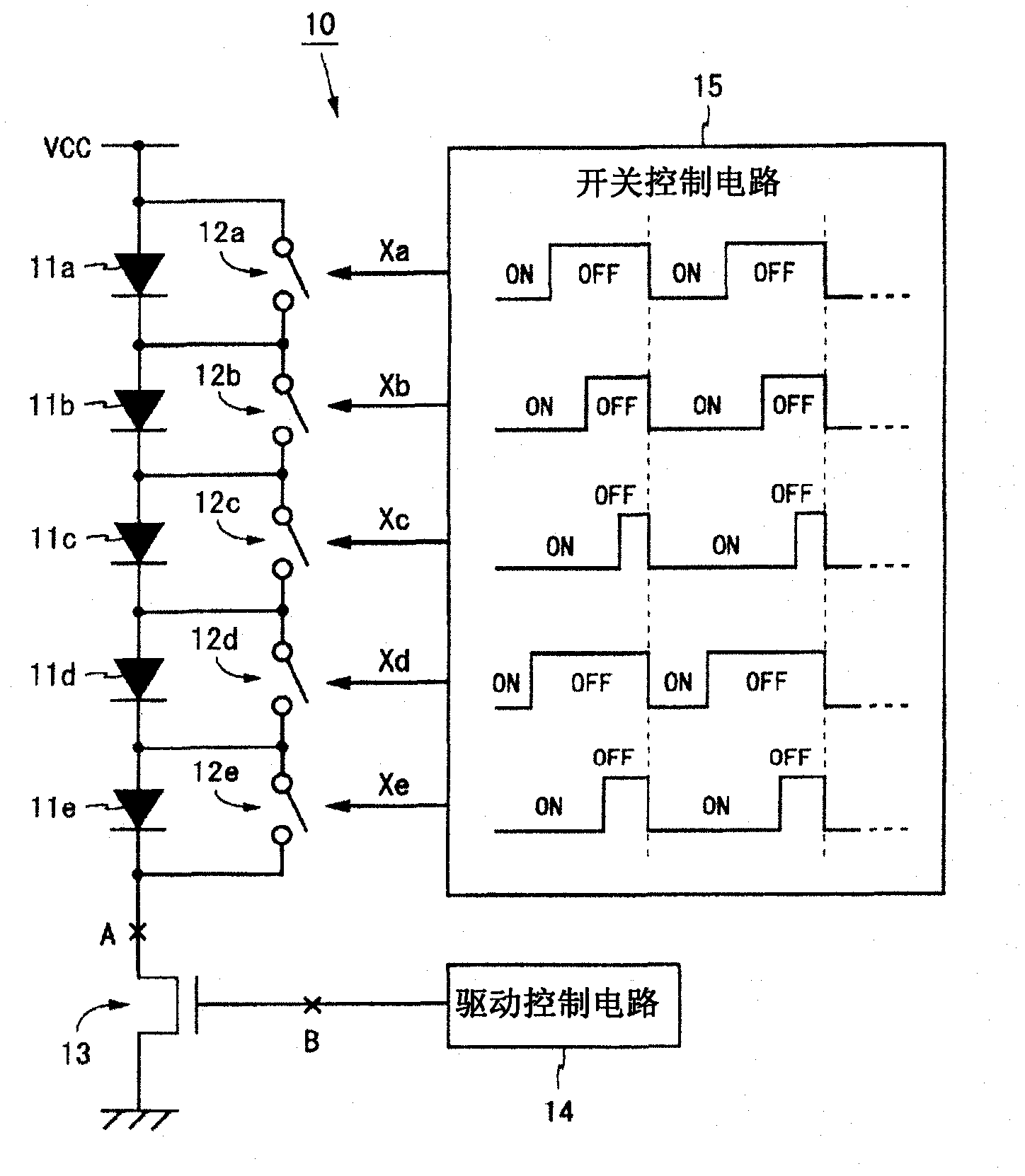

[0048] figure 1 It is a block diagram showing the configuration of the LED drive circuit according to the first embodiment of the present invention. figure 1 The shown LED drive circuit 10 includes switches 12a-12e, FET13, drive control circuit 14 and switch control circuit 15, and drives LEDs 11a-11e with a constant current. In addition, five LEDs are driven by the LED driving circuit 10 here, but the number of LEDs driven by the LED driving circuit 10 may be arbitrary as long as it is two or more. In other words, the LED drive circuit 10 that drives two or more LEDs has effects described later.

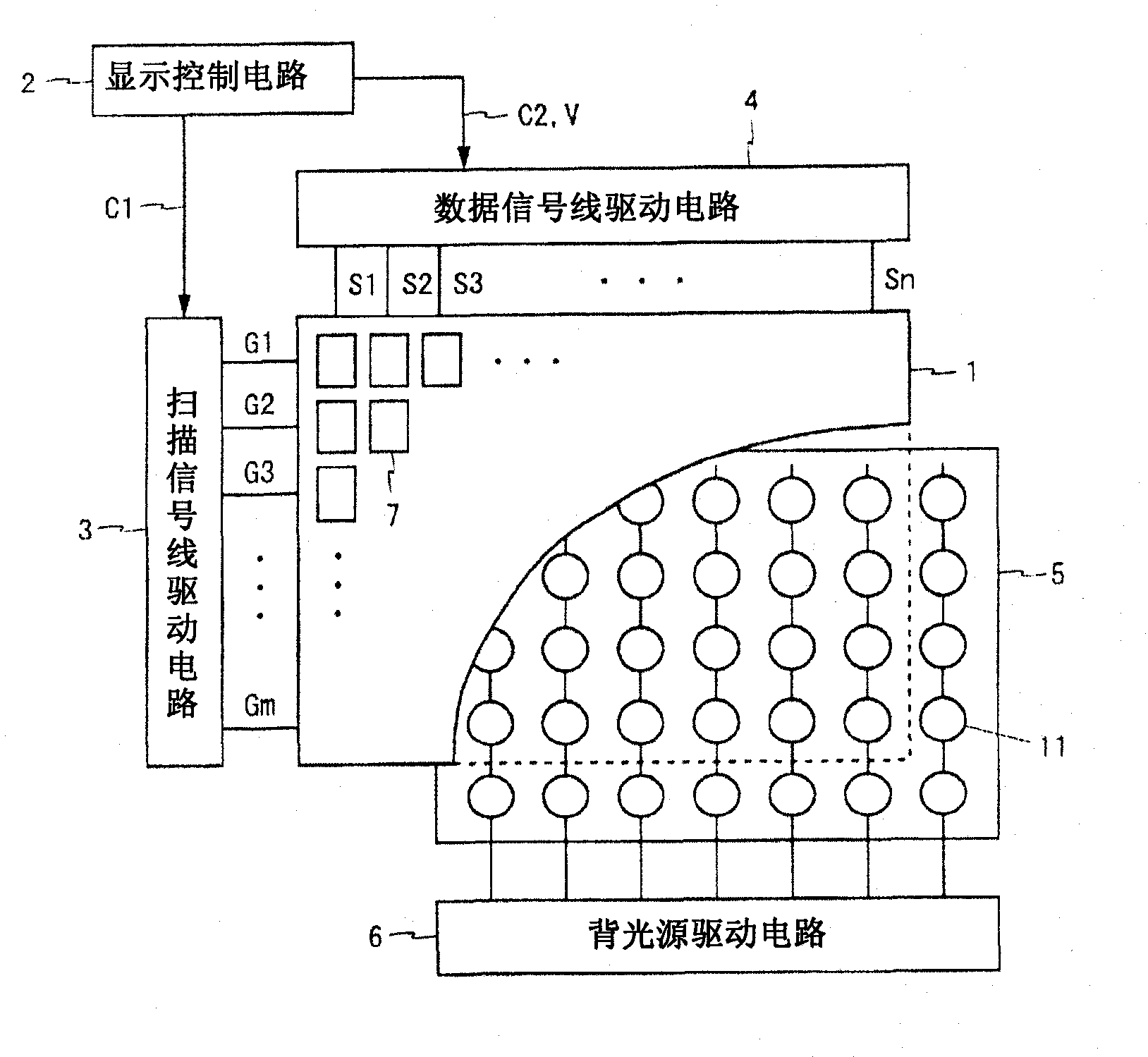

[0049] Before describing the LED drive circuit 10 in detail, refer to figure 2 An example of how to use the LED drive circuit 10 will be described. figure 2 It is a block diagram showing the configuration of a liquid crystal display device including the LED drive circuit 10 . figure 2 The shown liquid crystal display device includes a liquid crystal panel 1 , a display cont...

no. 2 approach

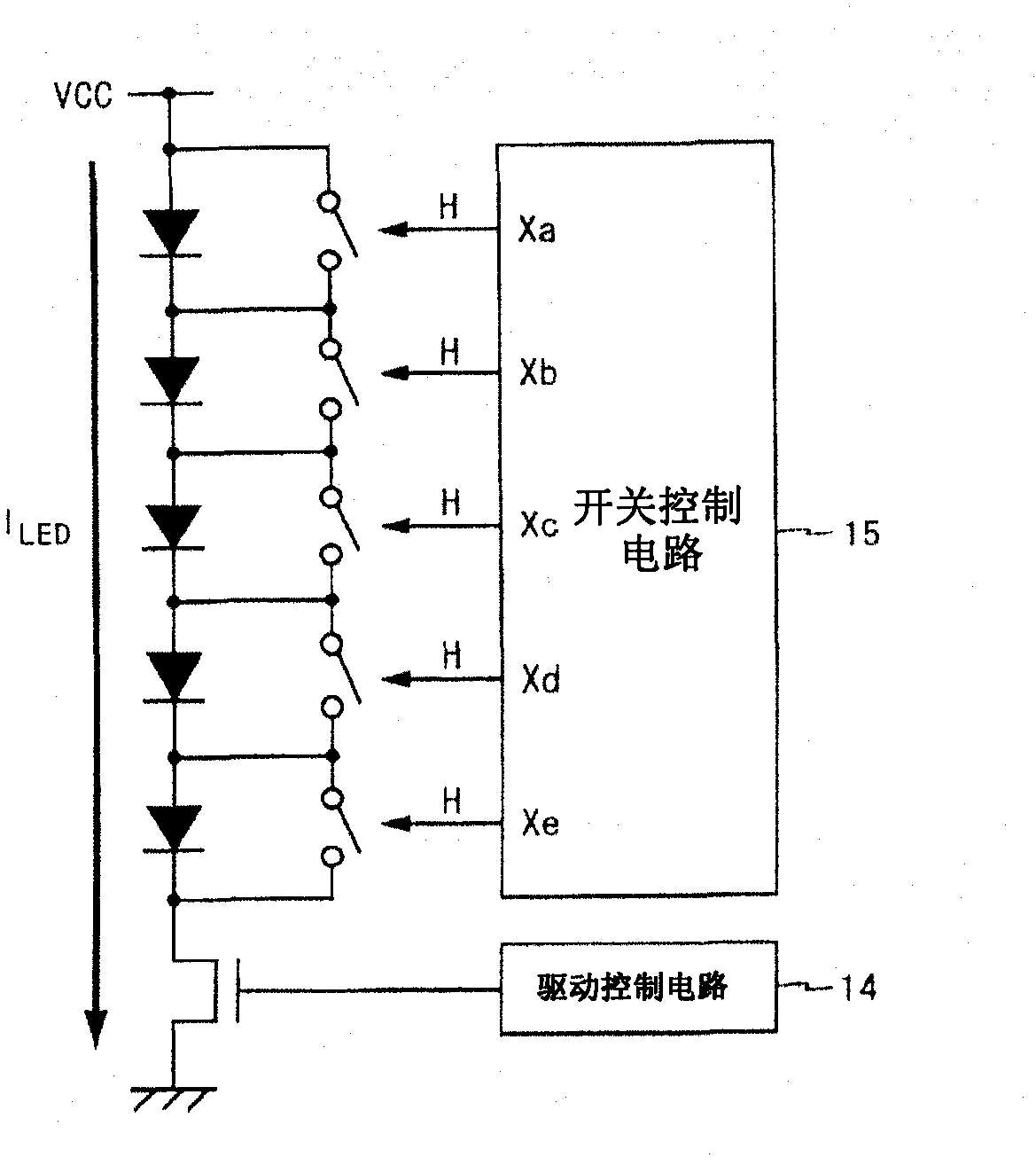

[0065] Figure 6 It is a block diagram showing the configuration of the LED drive circuit according to the second embodiment of the present invention. Figure 6 The LED driving circuit 20 shown is obtained by combining the LED driving circuit 10 ( figure 1 ) is formed by replacing the drive control circuit 14 and the switch control circuit 15 with the drive control circuit 24 and the switch control circuit 25. Among the constituent elements of the present embodiment, the same elements as those of the first embodiment are denoted by the same reference numerals, and description thereof will be omitted.

[0066] Like the drive control circuit 14, the drive control circuit 24 controls the gate voltage of the FET 13 so that the amount of drive current matches a predetermined target value. The switch control circuit 25 individually controls the on and off of the switches 12a to 12e like the switch control circuit 15, and changes all the switches 12a to 12e from the off state to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com