Liquid processing apparatus, liquid processing method and storage medium

A storage medium and liquid processing technology, which is applied in the field of liquid processing, can solve the problems that cannot be processed, the exhaust volume of the cup body is expected to be reduced, and the wafer manufacturing efficiency has little contribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

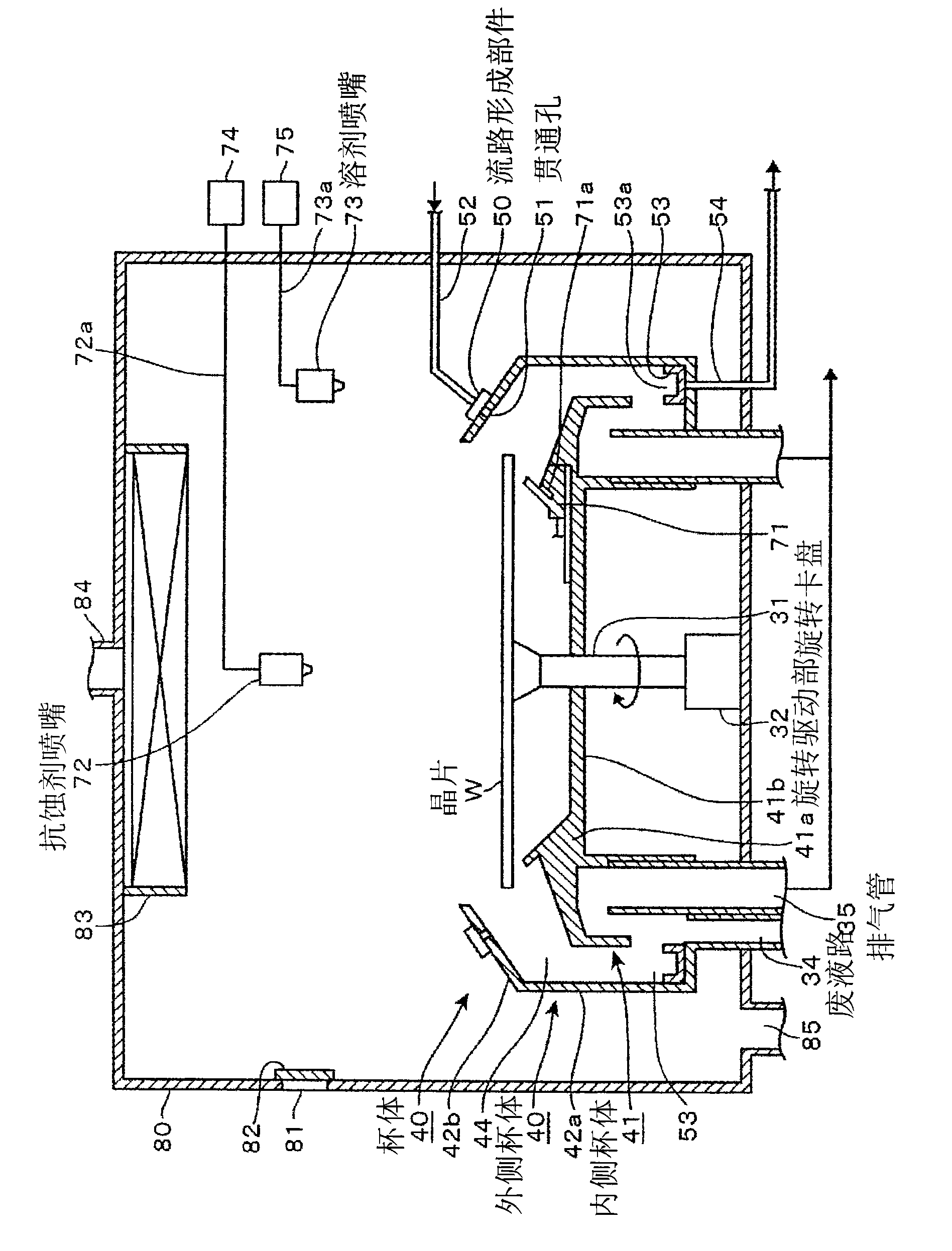

[0057] An embodiment in which the liquid processing device of the present invention is applied to a resist coating device will be described. figure 1 The shown resist coating apparatus has a spin chuck 31 that holds a wafer W horizontally by vacuum suction. The spin chuck 31 can be raised and lowered by a rotary drive unit 32 connected below, and can rotate about a vertical axis. A cup 40 is provided to surround the spin chuck 31 , and the cup 40 is composed of an inner cup 41 and an outer cup 42 .

[0058]The inner cup body 41 is located below the wafer W held by the spin chuck 31, and is composed of an annular guide portion 41a and a horizontal disc portion 41b. The position of the circular plate portion 41 b is connected to the inner periphery of the guide portion 41 a, and the central portion is penetrated by the spin chuck 31 . The above-mentioned guide portion 41 a has a function of guiding (guiding) the flow of the resist liquid spilled from the wafer W. As shown in ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap