Single-shaft high-precision intelligent linear motion mechanical arm

A linear motion, high-precision technology, applied to manipulators, program-controlled manipulators, conveyor objects, etc., can solve problems such as complicated internal maintenance and replacement, increased control difficulty, and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

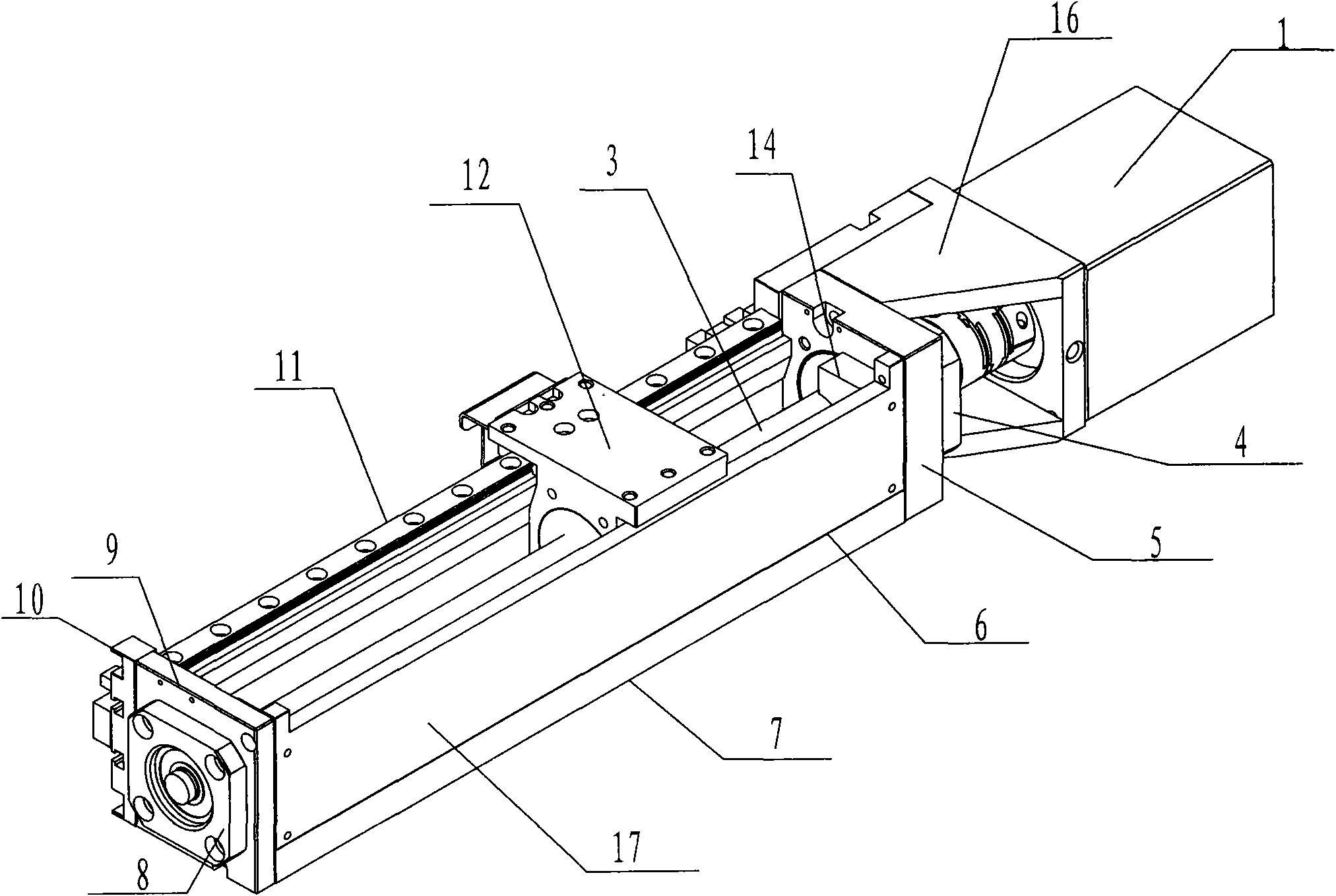

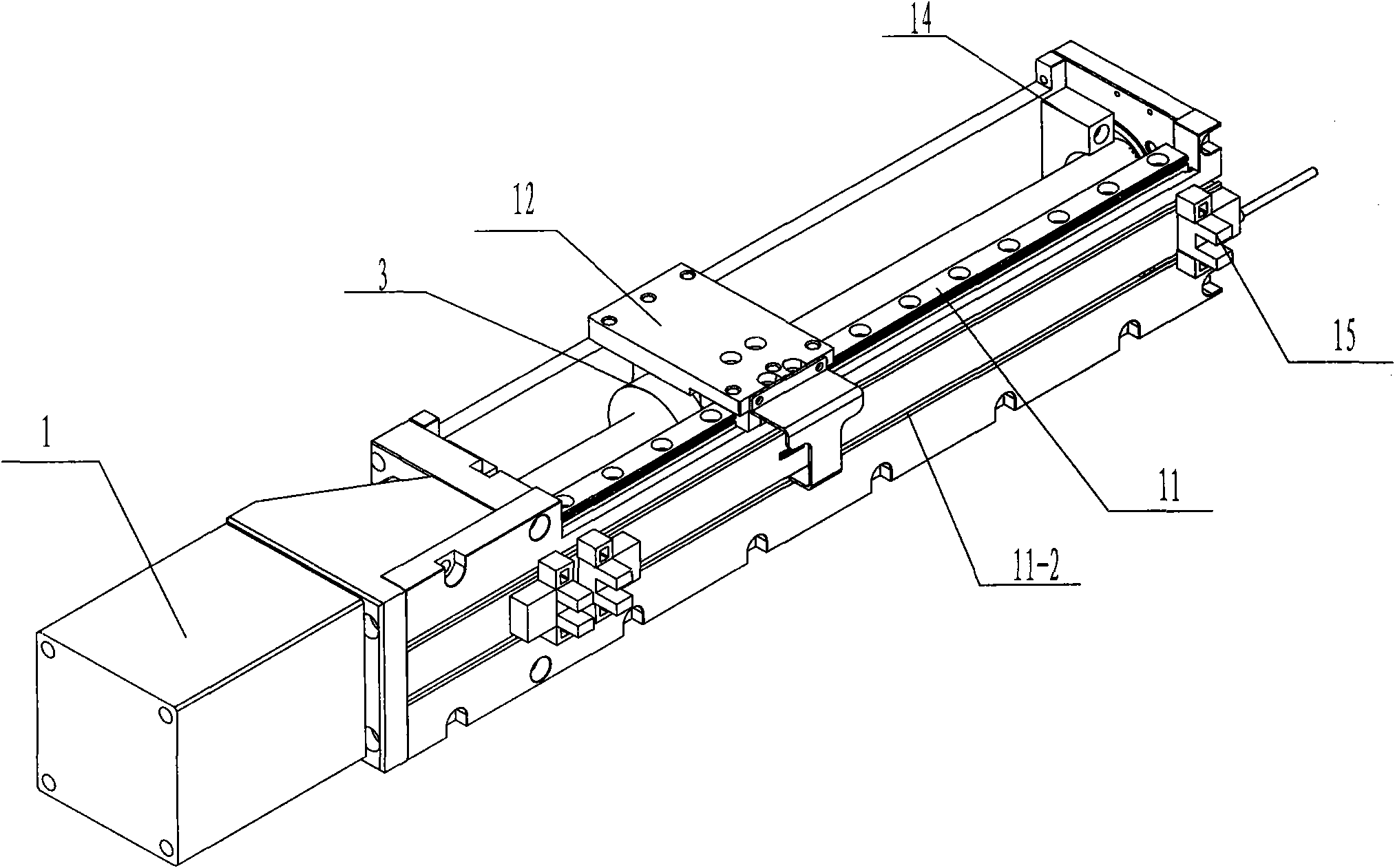

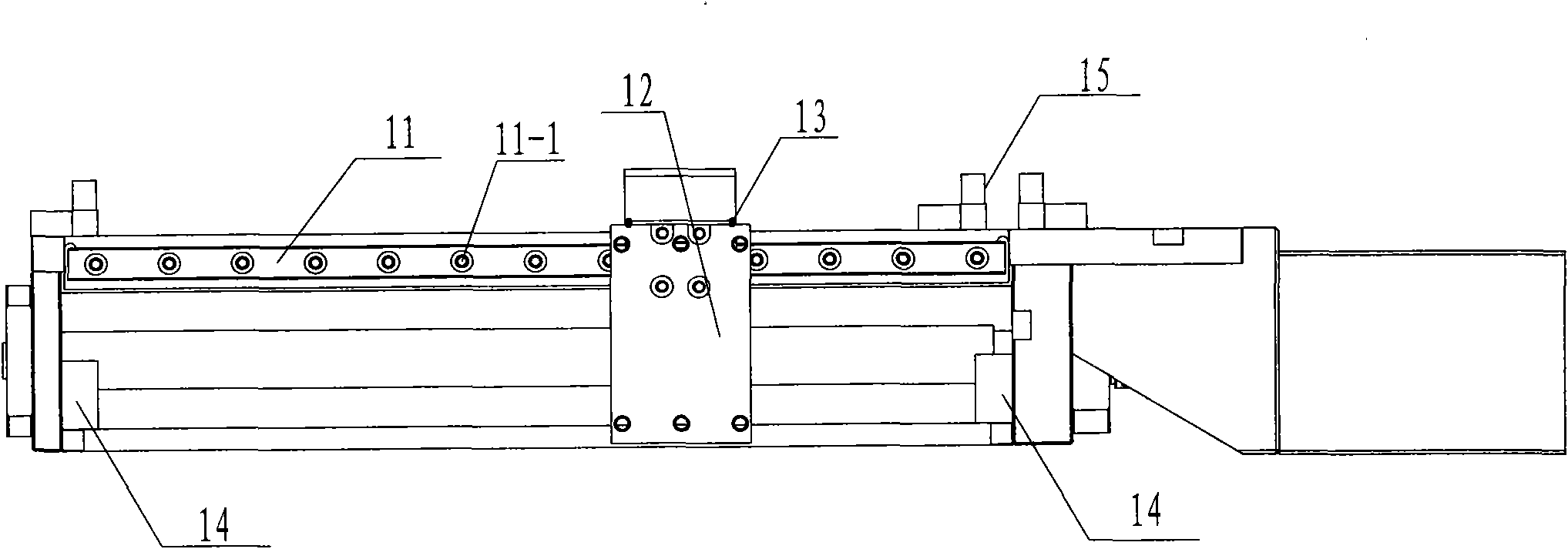

[0014] figure 1 , figure 2 A single-axis high-precision intelligent linear motion manipulator with mechanical transmission is shown, which mainly includes a motor 1, a ball screw 3 rotationally connected to the motor 1 through a coupling 2, and an upper opening and closing arm 17 wrapped around the ball screw 3 1. Connect the opening and closing arm 17 and the flange seat 16 of the motor 1. The composition of the opening and closing arm 17 is sequentially composed of the fixed bearing seat 4, the main support seat 5 inside the fixed bearing seat 4, the bottom plate 7, and the side sealing plate. 9. The secondary support 10 on the outside of the side sealing plate 9 and the supporting bearing seat 8 connected to the outside of the side sealing plate 9 are characterized in that: a sliding sliding connection with the ball screw 3 is added above the opening and closing arm 17. Block 12, offers two slide rail grooves 12-1 in the side plate 6 outsides of opening and closing arm 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com