Preparation method of adhesive material

A technology for bonding materials and polymers, applied in the direction of one-component synthetic polymer rayon, one-component polyolefin rayon, one-component polyamide rayon, etc. Poor controllability of the structure, cumbersome steps and other problems, to achieve the effect of good adhesion performance, mild conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

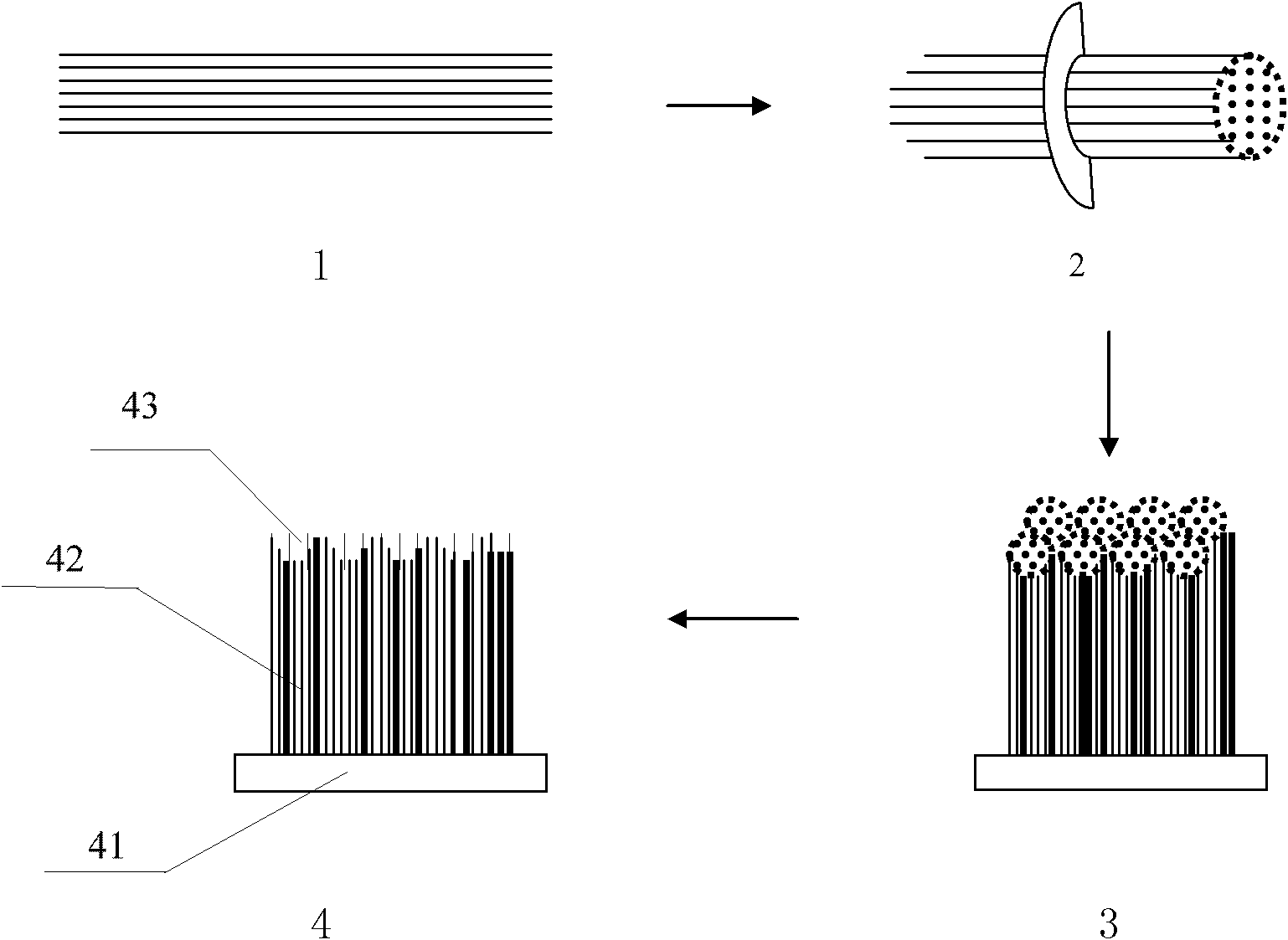

[0031] The invention provides a kind of preparation method of bonding material, comprises the following steps:

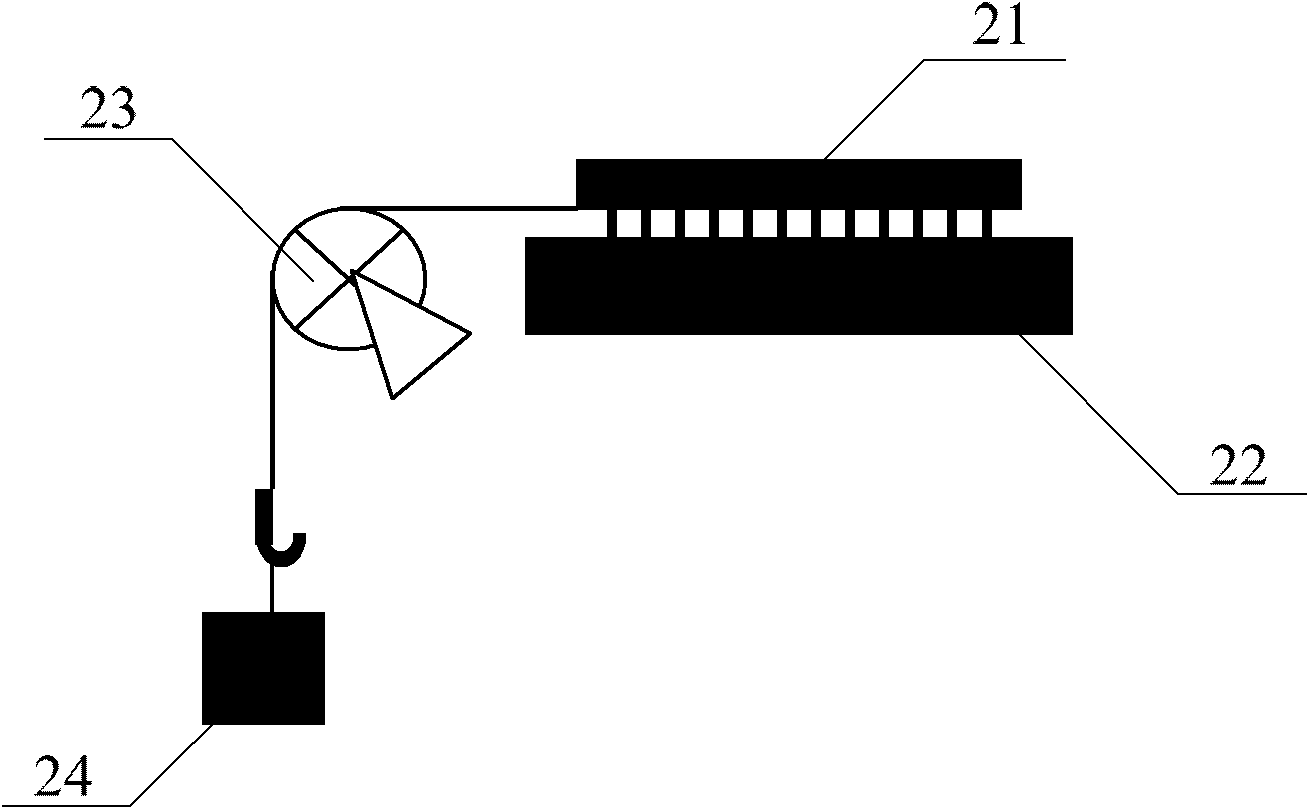

[0032] Electrospinning the polymer, collecting the fibers through a turntable or a drum to obtain oriented polymer fibers;

[0033] bundling the oriented polymer fibers to obtain oriented polymer fiber bundles;

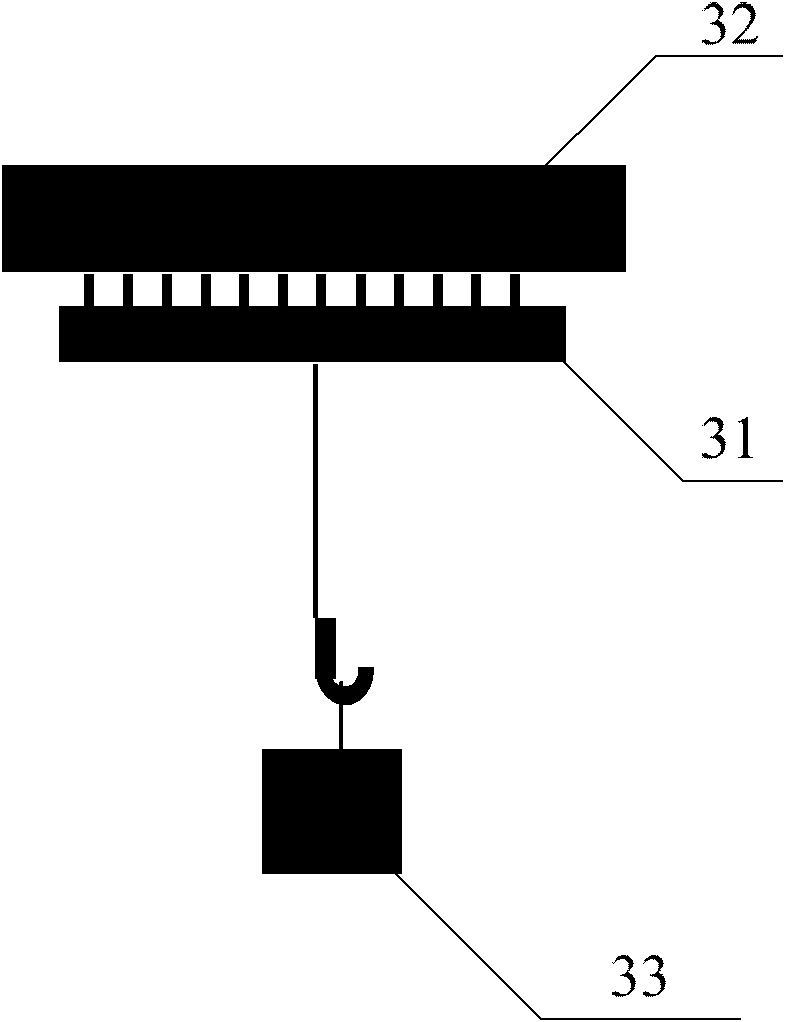

[0034] Fixing one end of the oriented polymer fiber bundle on the base, and forming a plane at the other end;

[0035] After etching one end of the oriented polymer fiber bundle forming a plane to form superfine fibers, an adhesive material is obtained.

[0036] The present invention also provides a kind of preparation method of bonding material, comprises the following steps:

[0037] Electrospinning the polymer and collecting the fibers in the presence of a magnetic field to obtain oriented polymer fibers;

[0038] bundling the oriented polymer fibers to obtain oriented polymer fiber bundles;

[0039] Fixing one end of the oriented polymer fiber bundl...

Embodiment 1

[0076] Under the condition of 80°C to 100°C, use formic acid as a solvent to prepare a nylon 6 solution with a mass concentration of 15%;

[0077]Put the nylon 6 solution in a 10mL plastic needle tube, use a needle with a diameter of 1mm, and use the above-mentioned electrospinning equipment for spinning, the conditions are as follows: the high voltage voltage is 16kV-25kV, and the solution flow rate is 0.03mL / h-3mL / h, using a rotating disk to collect polymer fibers, the rotating speed of the rotating disk is 200 revolutions / s, the distance from the needle to the rotating disk receiver is 10cm, to obtain oriented polymer fibers, the diameter of the oriented polymer fibers is about 1000nm;

[0078] The oriented polymer fibers are segmented and bundled into bundles, and the obtained fiber bundles have a length of 0.5 mm and a diameter of 1 mm; one end of a plurality of the fiber bundles is simultaneously fixed on a polypropylene film with a thickness of 200 μm by epoxy resin On...

Embodiment 2

[0088] Prepare the adhesive material according to the raw materials, methods and steps provided in Example 1, the difference is that an ultra-fine fiber structure is formed at one end of the fiber bundle forming plane by ultraviolet lithography to obtain the adhesive material, and the ultraviolet light The irradiation time is 60s-300s, and the distance between the free end of the fiber bundle and the ultraviolet light source is 3cm-5cm.

[0089] An electron microscope scan is performed on the adhesive material, and the end of the adhesive material has a superfine fiber structure with a diameter of 20nm-50nm.

[0090] The shear bond strength, peel strength and repeated use times of the adhesive material on the glass surface, polymethyl methacrylate material surface and polystearyl acrylate material surface were respectively analyzed by the experimental method described above, See Table 1 for the results. Table 1 shows the test results of the adhesive properties of the adhesive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com