Rotor for a wind power plant

A technology of wind power generation equipment and rotors, which is applied in the control of wind power generators, wind power generation, wind power generators, etc. It can solve the problems that maintenance personnel are difficult to access the drive, and achieve the effects of easy maintenance, easy access, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

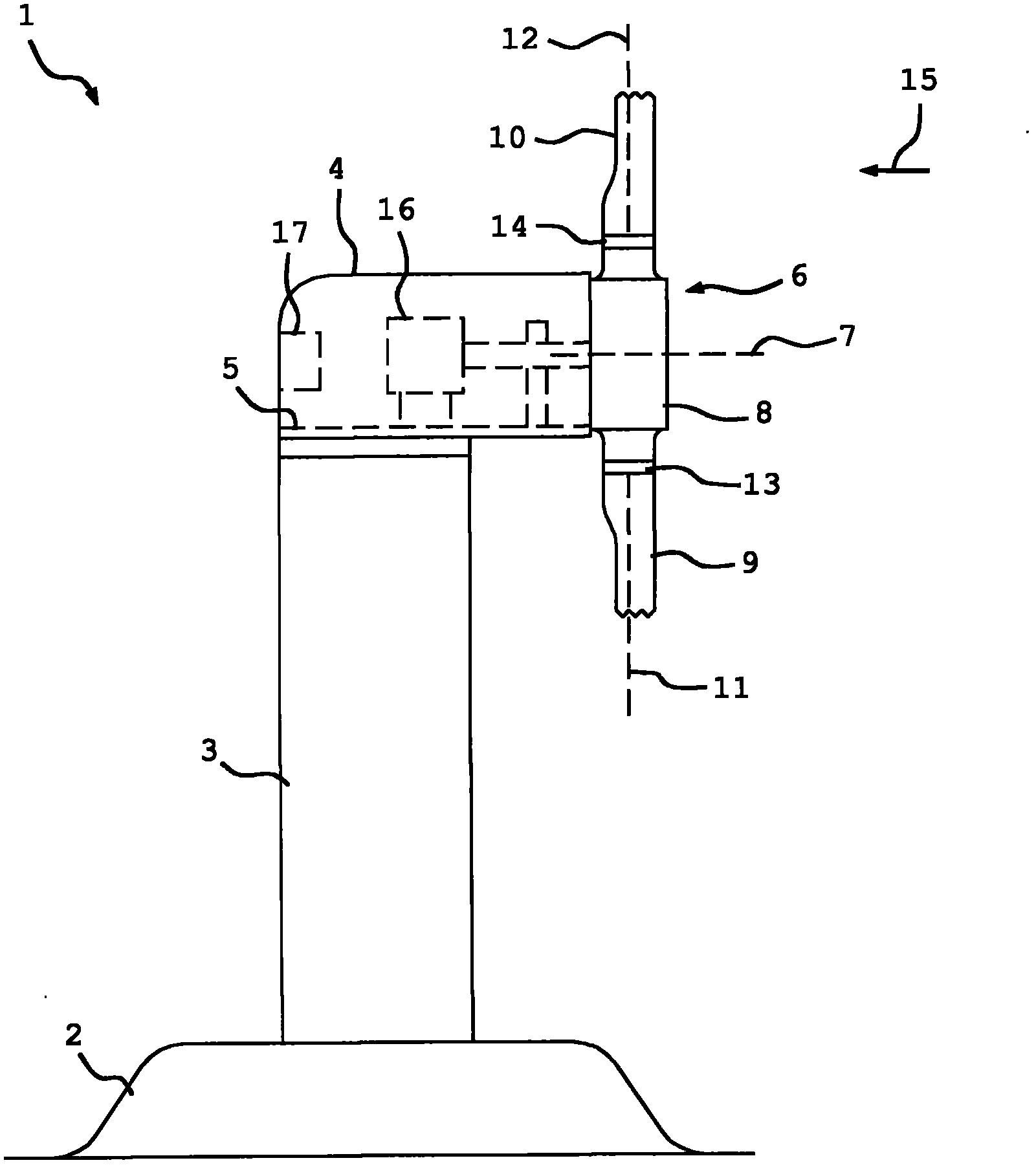

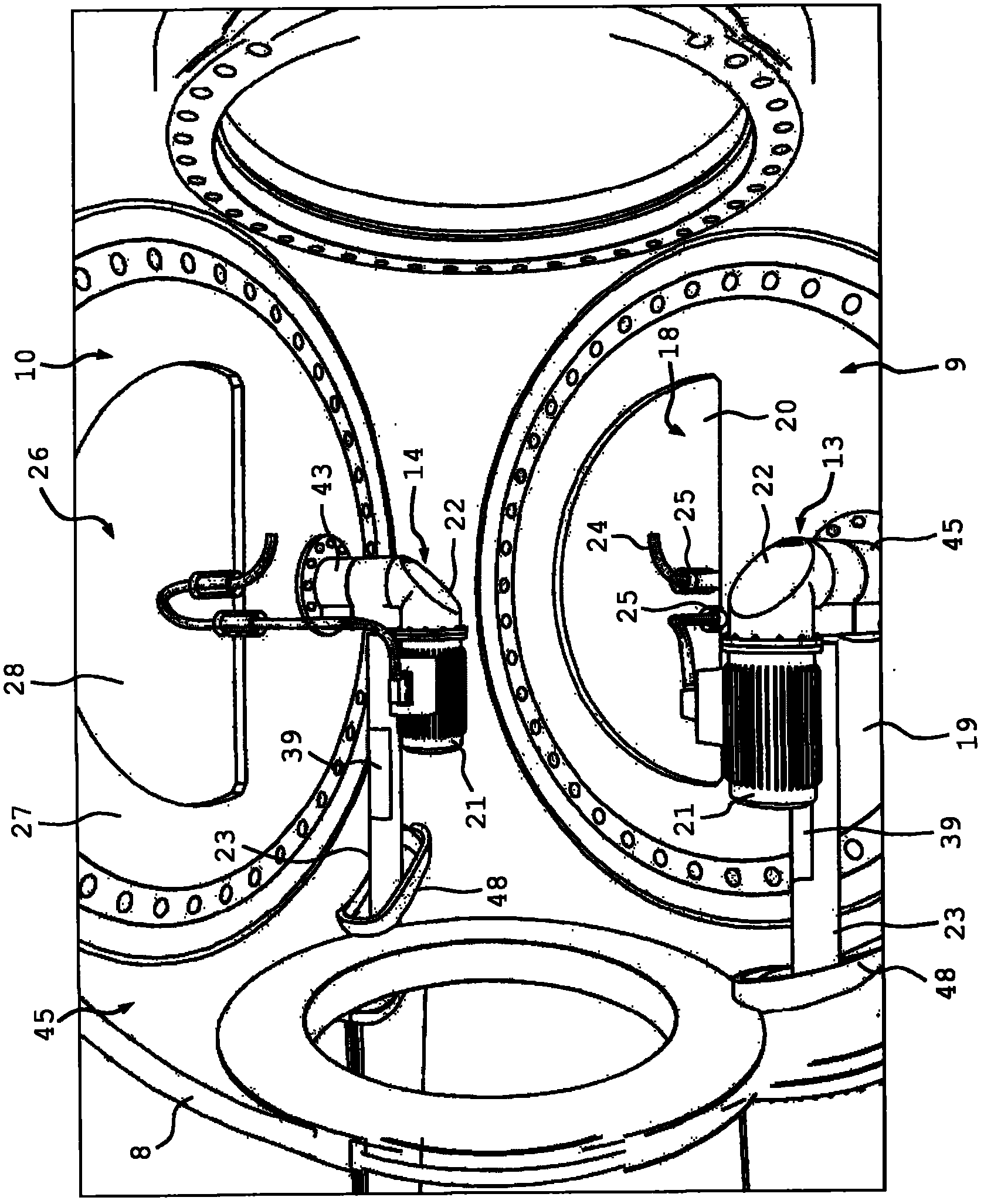

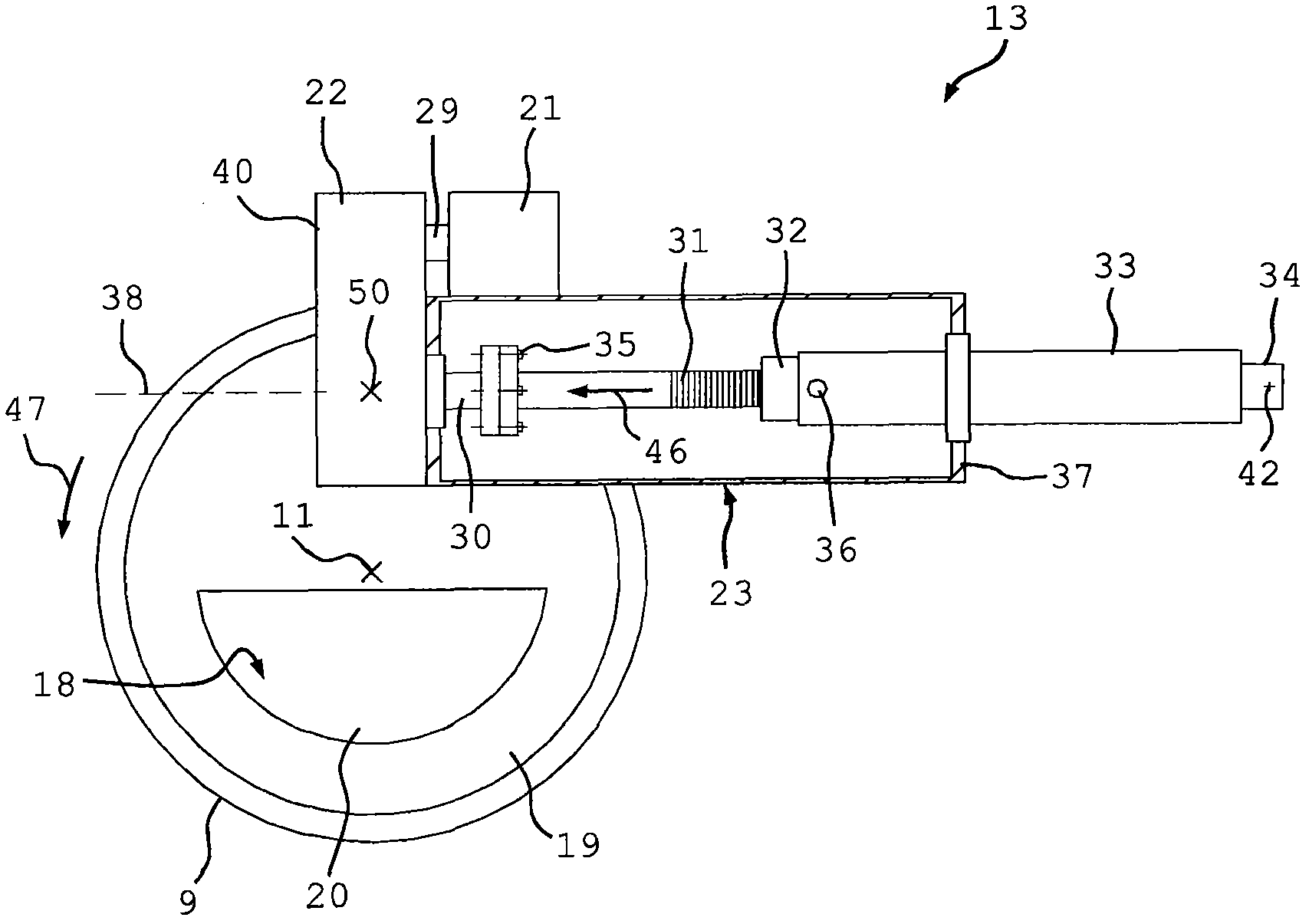

[0028] Depend on figure 1 A wind power plant 1 is shown in which a tower 3 rising from a foundation 2 is connected at its end facing away from the foundation 2 to a machine room 4 . The machine room 4 comprises a machine frame 5 on which a rotor 6 is mounted rotatably about a rotor axis 7 and has a rotor hub 8 and connected thereto rotor blades 9 and 10 which are respectively rotatable around them. The blade axis 11 or 12 rotates relative to the rotor hub 8 . The rotor blades 9 and 10 are each mechanically coupled to a blade angle adjustment drive 13 or 14 , by means of which the individual rotor blades can be rotated about the associated blade axis. The rotor 6 is rotatable by the wind 15 about the rotor axis 7 and is mechanically coupled to a generator 16 which is fixed on the machine frame 5 and is arranged in particular in the machine room 4 . For controlled operation of the wind power plant 1 , a wind power plant control device 17 is provided, by means of which wind pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com