Brake system for a wind turbine with integrated rotor lock, generator and wind turbine

A braking system and generator technology, applied in wind turbine components, control of wind turbines, wind power generation, etc., to achieve the effect of increasing braking efficiency, easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

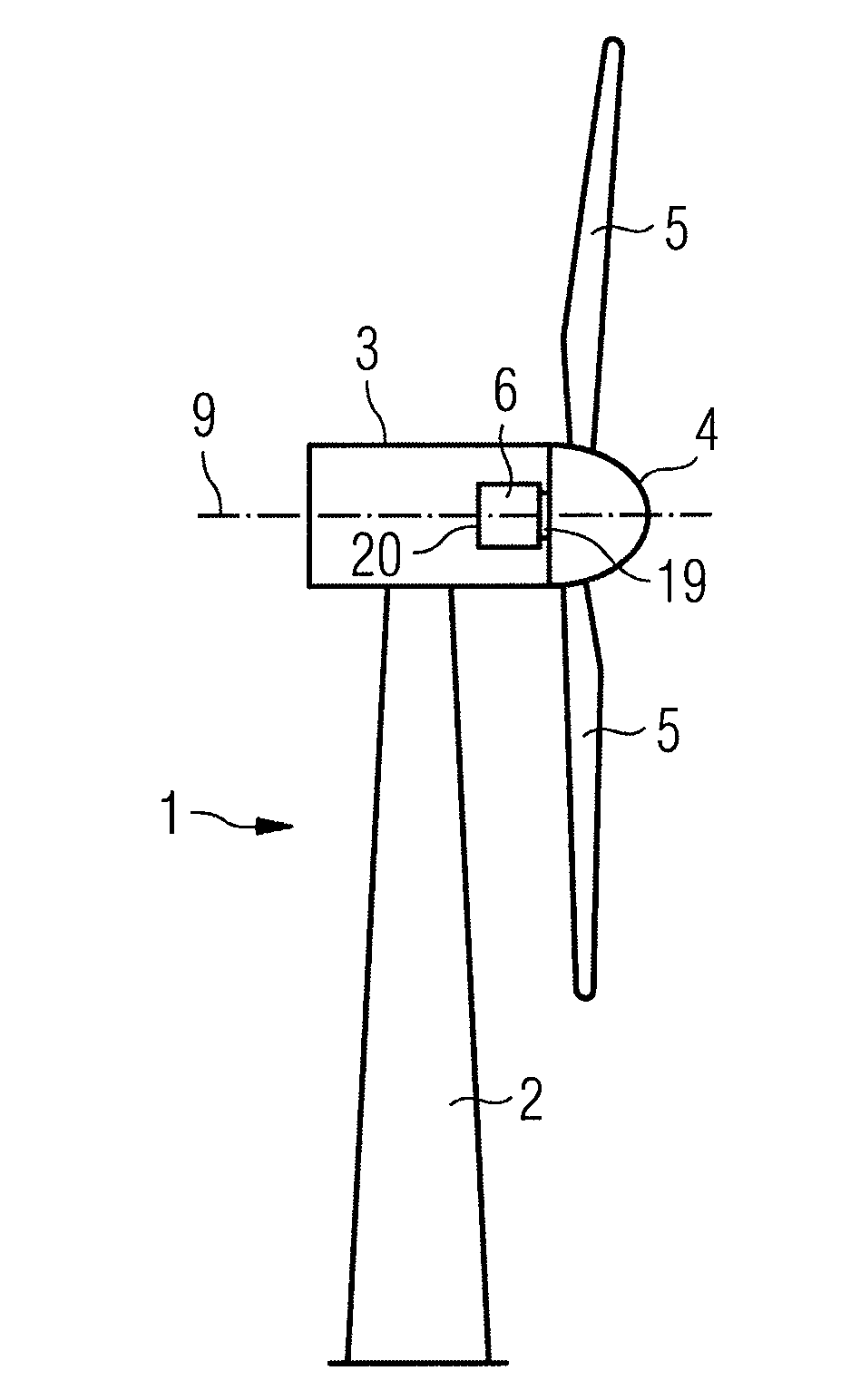

[0045] will now refer to Figure 1-7 Embodiments of the present invention are described. figure 1 A wind turbine 1 is shown schematically. Wind turbine 1 comprises a tower 2 , a nacelle 3 and a hub 4 . Nacelle 3 is located on top of tower 2 . The hub 4 comprises a plurality of wind turbine blades 5 . Hub 4 is mounted to nacelle 3 . Furthermore, the hub 4 is pivotally mounted so that it can rotate about an axis of rotation 9 . The generator 6 is located inside the nacelle 3 . The wind turbine 1 is a direct drive wind turbine. The generator 6 comprises a proximal side 19 facing the hub 4 and a distal side 20 opposite the hub 4 .

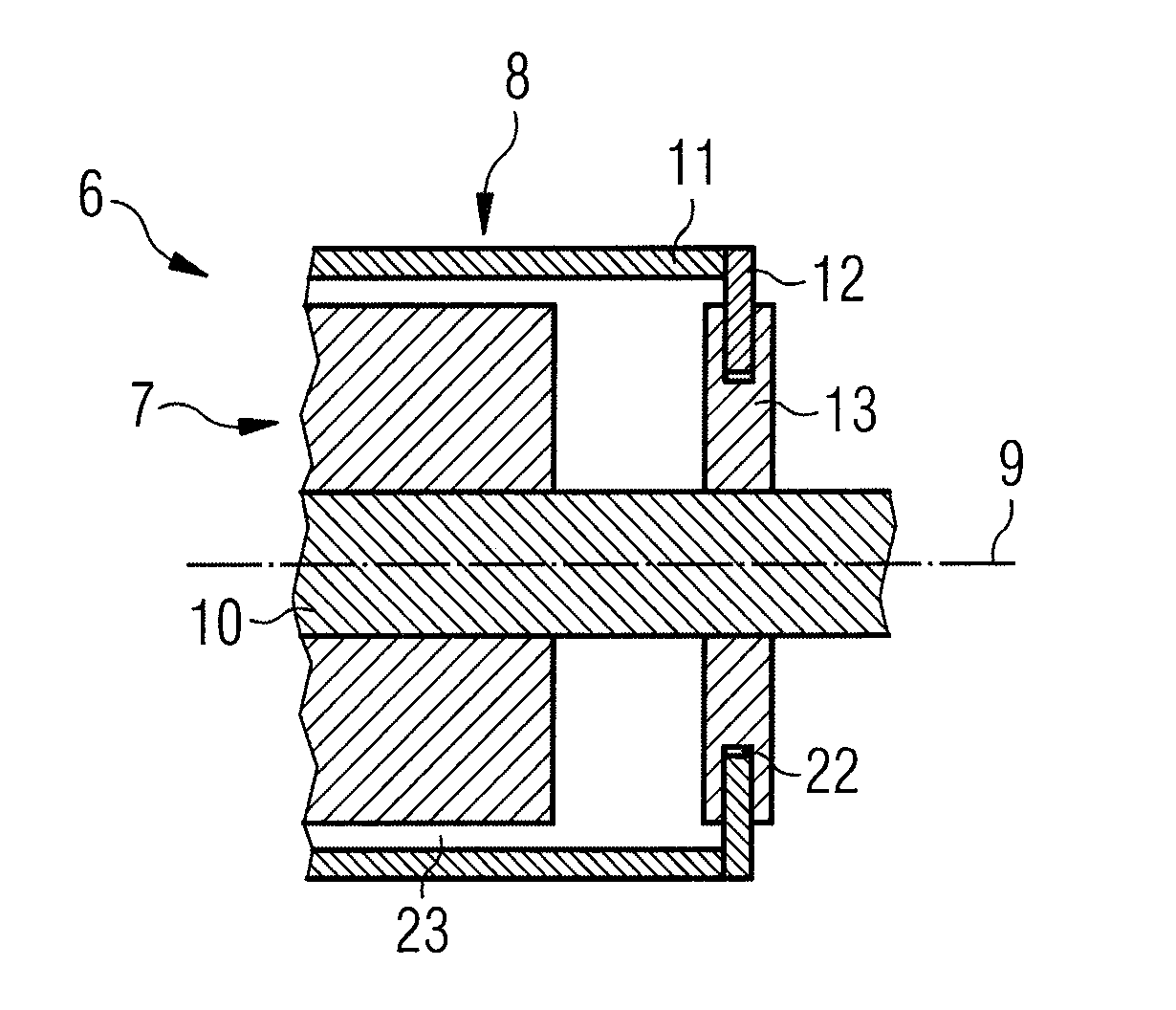

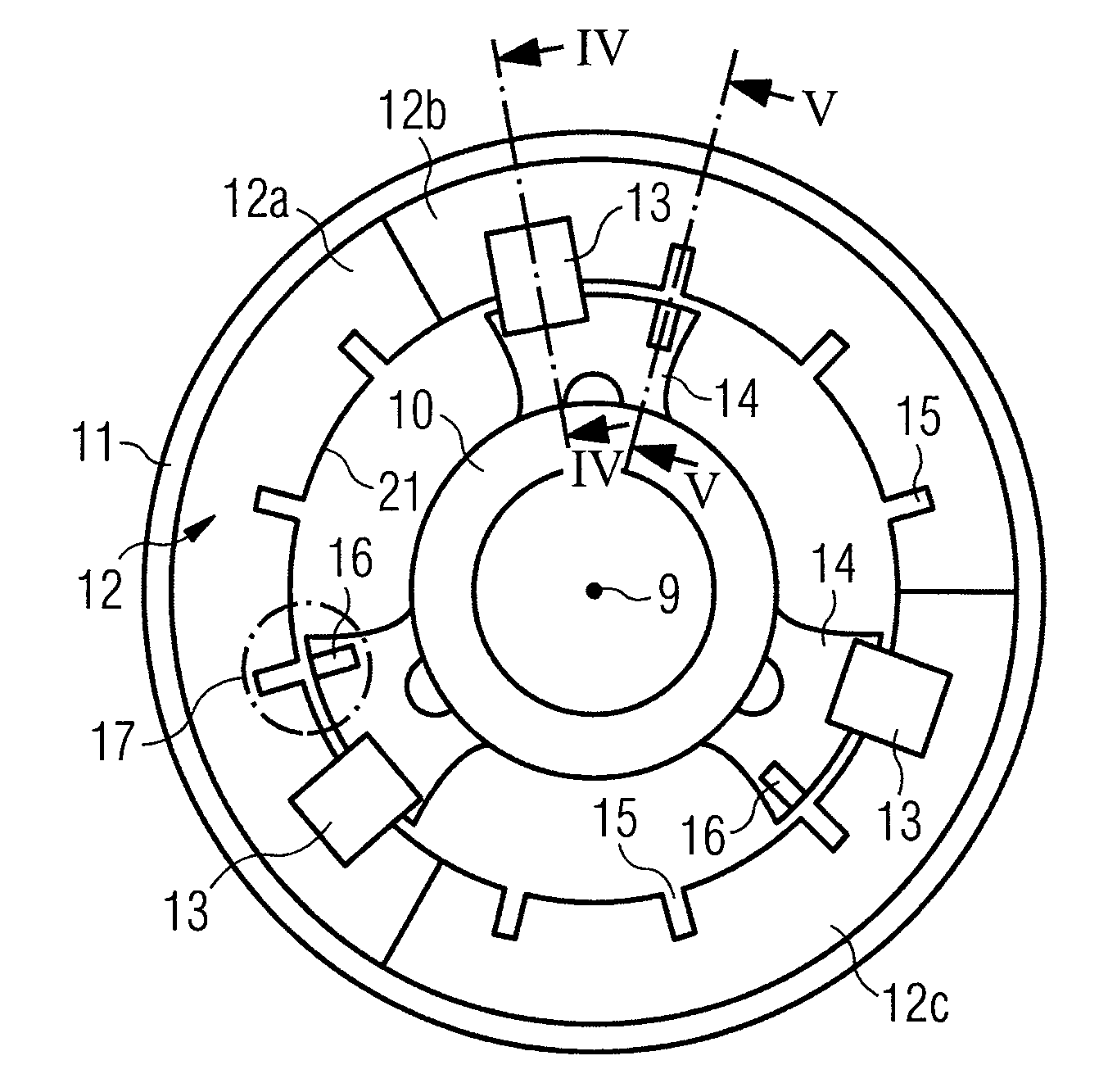

[0046] figure 2 A part of a generator 6 with an external rotor configuration is shown schematically in cross-section. The generator 6 includes a stator assembly 7 and a rotor assembly 8 . The stator assembly 7 includes a fixed shaft 10 positioned close to the axis of rotation 9 . The rotor assembly 8 comprises an outer rotor part 11 positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com