LED (Light-Emitting Diode) plane light source and method for increasing light guiding efficiency thereof

A technology of LED light source and plane light source, applied in the field of light sensing engineering application, can solve the problems of affecting the brightness of lamps, reducing the luminous efficiency of lamps, light loss, etc., and achieving the effects of reducing light absorption, saving costs, and reducing the number of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

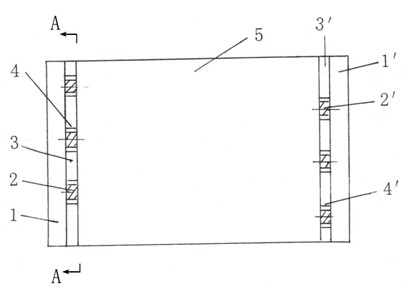

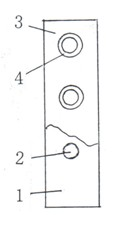

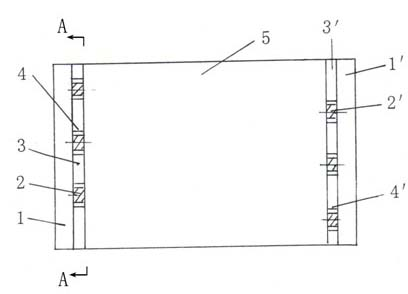

[0014] Depend on figure 1 and figure 2 As shown in the figure, a flat LED light source includes a light guide plate 5, LED light sources 2 respectively placed on opposite sides of the light guide plate 5, and a PCB circuit board 1 for fixing the LED light source 2 by welding. A layer of reflective layer 3 is placed between the side of the light plate 5 and the PCB circuit board 1, and a light outlet 4 is preset on the reflective layer 3 at the corresponding position of the LED light source 2, and the PCB circuit board 1-reflective layer 3 - The light guide plates 5 are closely attached to each other in sequence; the LED light sources 2 respectively placed on the opposite sides of the light guide plate 5 are intersected with each other and arranged complementary to each other.

[0015] The LED light source 2 is an LED lamp bead.

[0016] The reflective layer 3 is a PET light reflective film.

[0017] The method for improving the light-guiding efficiency of the LED flat ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com