Automatic follow machining method of numerically controlled machine tool

A CNC machine tool and automatic follow-up technology, applied in the direction of digital control, electrical program control, etc., can solve the problems affecting the machining size and machining accuracy, frequent blade damage, complicated machining programs and PLC programming, etc., and achieve the effect of ensuring machining accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

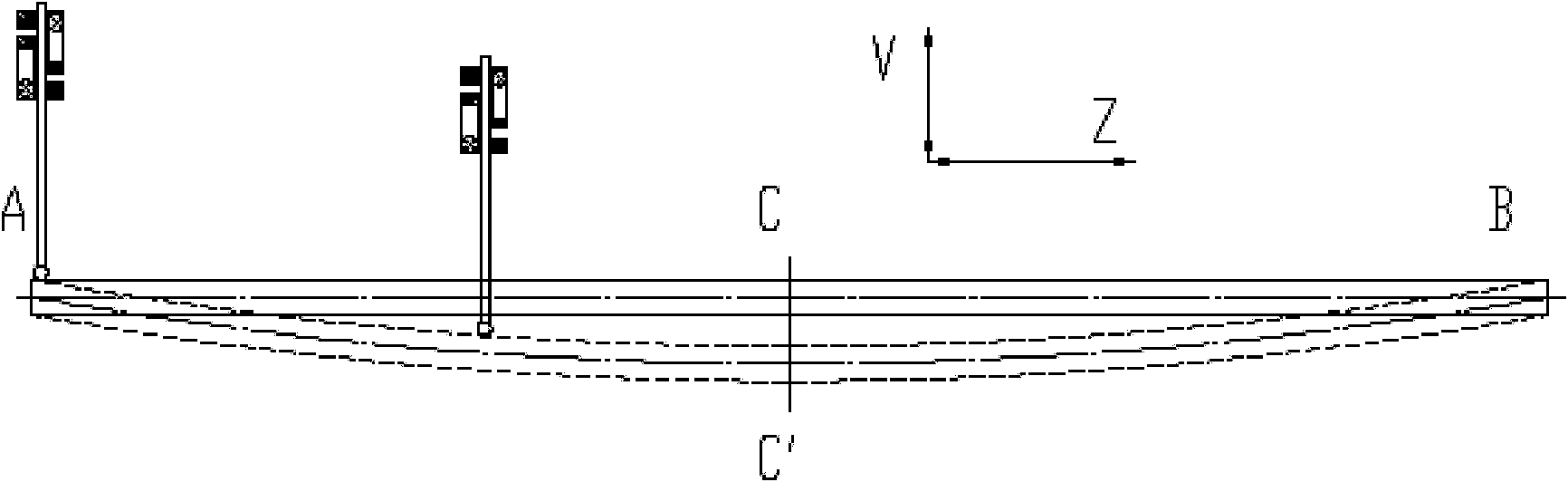

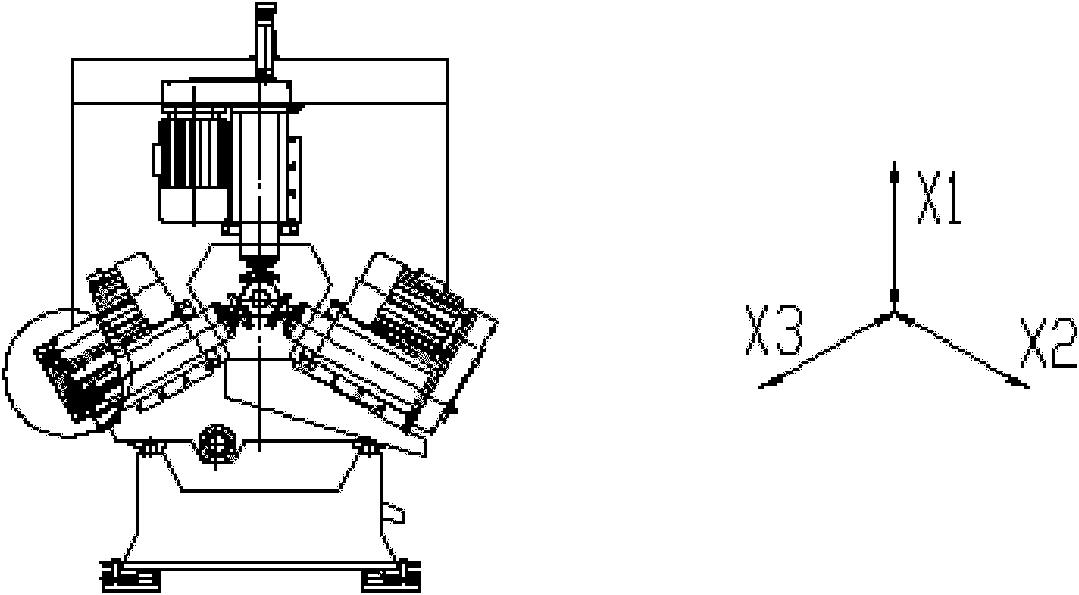

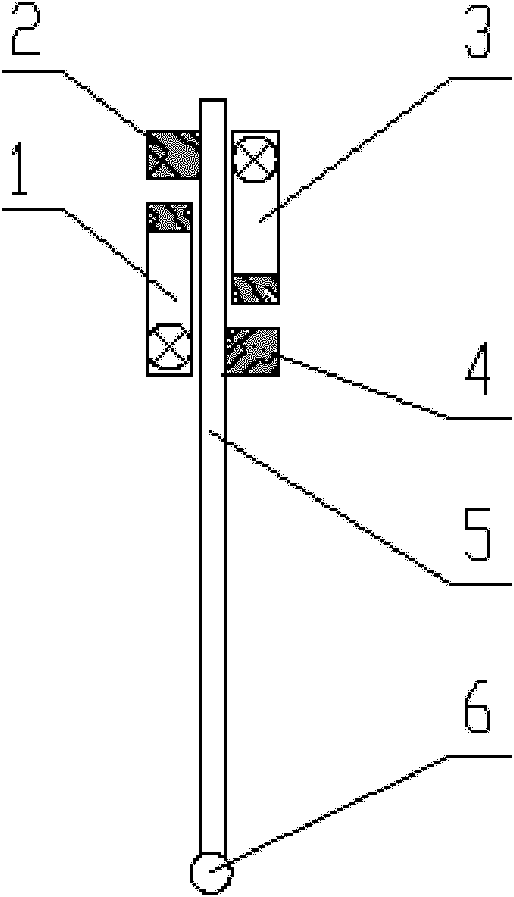

[0023] A method of automatic follow-up processing using CNC machine tools figure 1 The schematic diagram of the structure of the machined parts is shown, and the setting of the tool and the direction of the tool is as follows: figure 2 shown. The length of the workpiece to be processed is 12000mm, the diameter is 200mm, and the ratio of shaft diameter to size reaches 60:1. The solid line is the ideal contour of the workpiece, and the dotted line is the curved contour of the workpiece. According to the point C of the workpiece center, the workpiece to be processed is divided into two sections for processing: A-C' section, which is recorded as a section; C'-B section, which is recorded as b section. The specific processing method is as follows:

[0024] (1) Write the processing main program according to the workpiece processing requirements, set the following accurac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com