Field bus fault diagnostic method based on industrial computer

A fault diagnosis and field bus technology, applied in the field of control systems, can solve the problems of complex field bus fault detection, and achieve the effect of easy operation, system maintenance, and easy diagnosis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are enumerated hereby, and in conjunction with the accompanying drawings, the following of the present invention is described in detail:

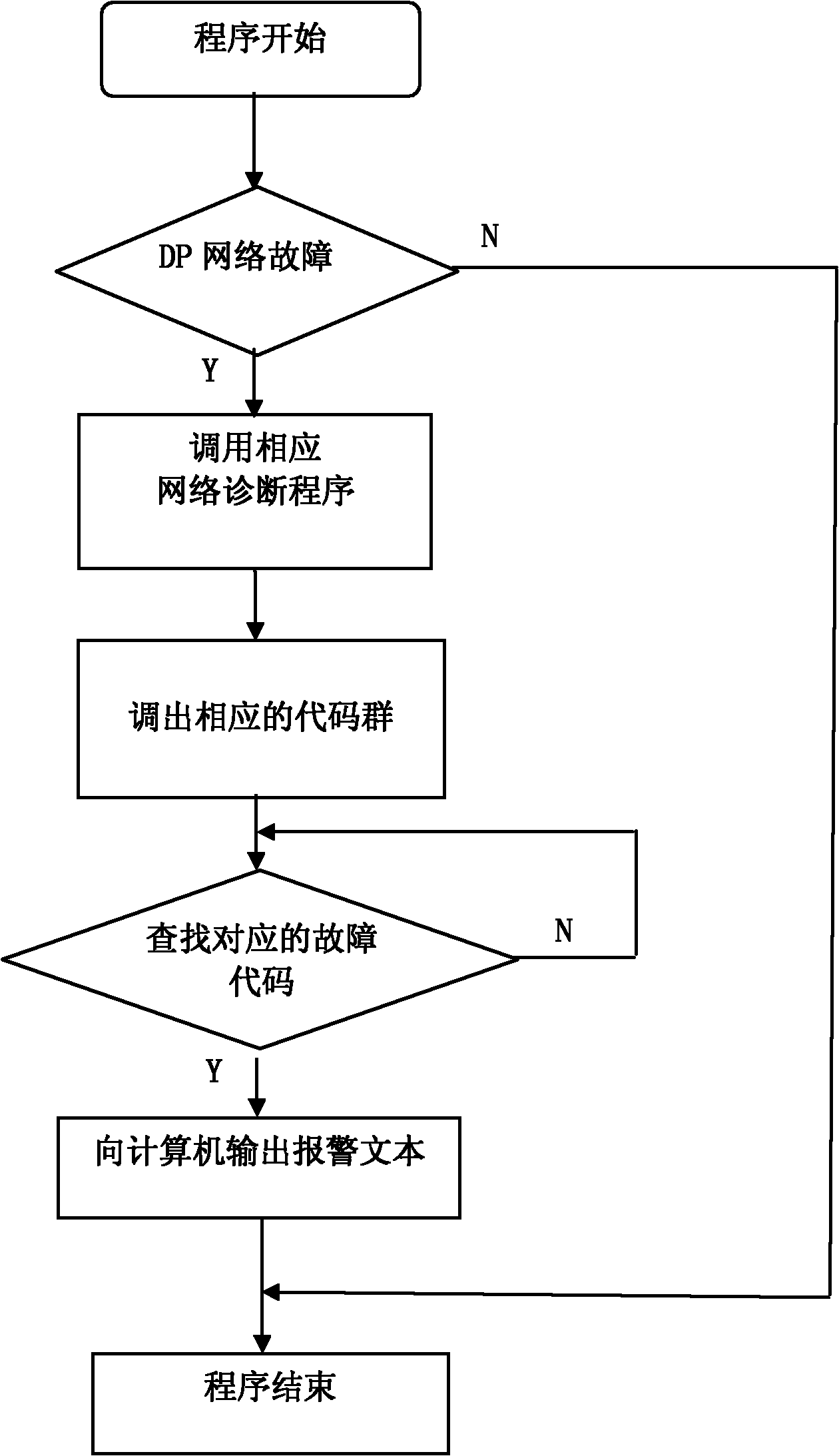

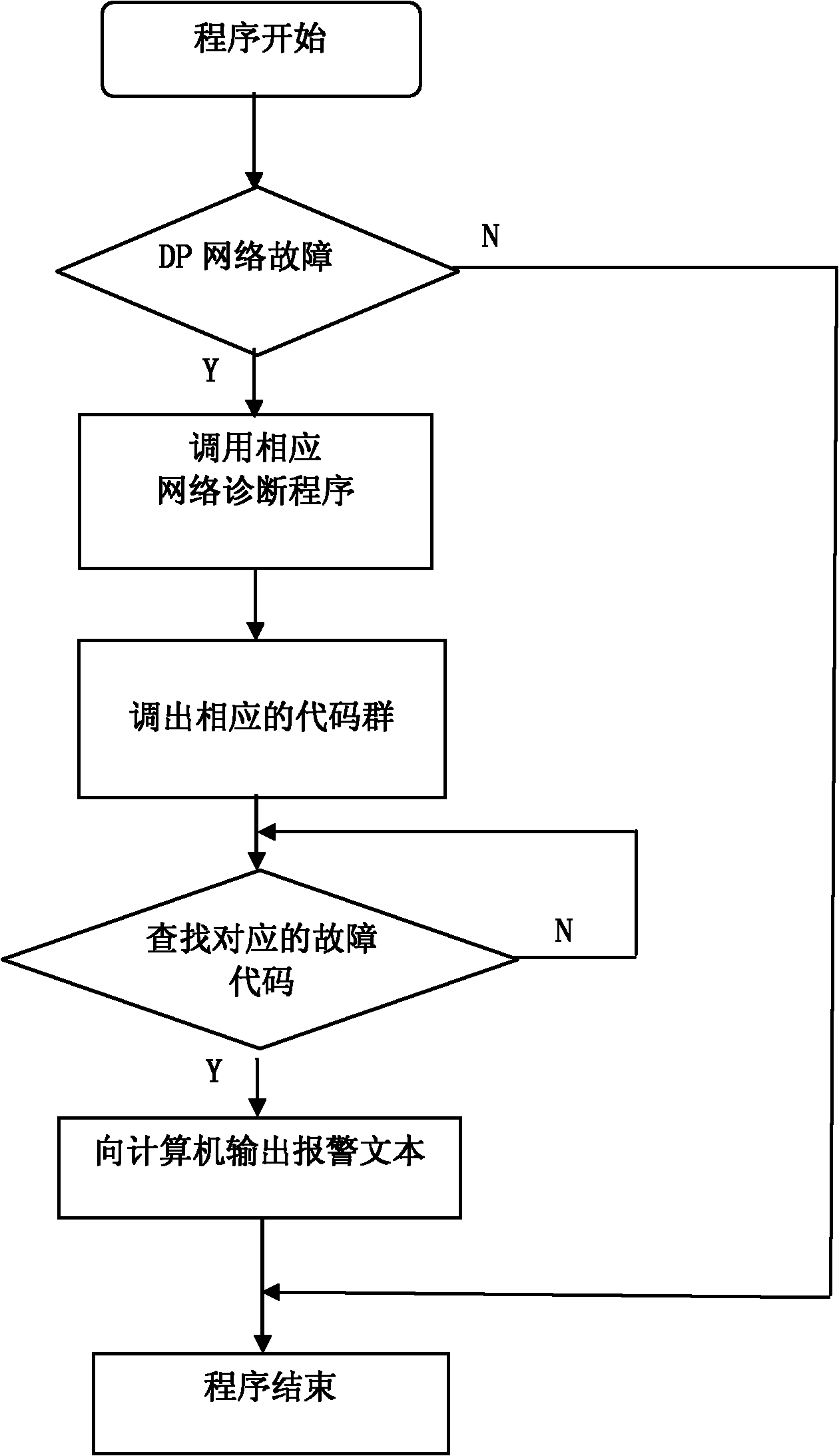

[0011] Such as figure 1 Shown, the fieldbus fault diagnosis method based on industrial computer of the present invention is based on Taiwan's Advantech industrial computer and utilizes Siemens' WinCC configuration software to develop press operating platform and Siemens PROFIBUS fieldbus diagnostic display system; programming in Siemens CPU416-2DP , once the field bus fails, the Siemens CPU416-2DP will call the field bus diagnostic program, and the CPU will feed back the field bus diagnostic information to the industrial computer, and the operator can clearly see the field line fault through the WinCC operation interface. Such as figure 1 As shown, when a bus fault occurs during the operation of the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com