Method and system for controlling temperature of engine room of wind generating set

A technology for wind turbines and temperature control systems, applied in control/regulation systems, temperature control, non-electric variable control, etc., can solve the problems of generator shutdown, unfavorable energy utilization, low heat exchange efficiency, etc., and improve normal work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The method and system for controlling the temperature of the nacelle of the wind power generating set according to the present invention will be described below with reference to the accompanying drawings and embodiments.

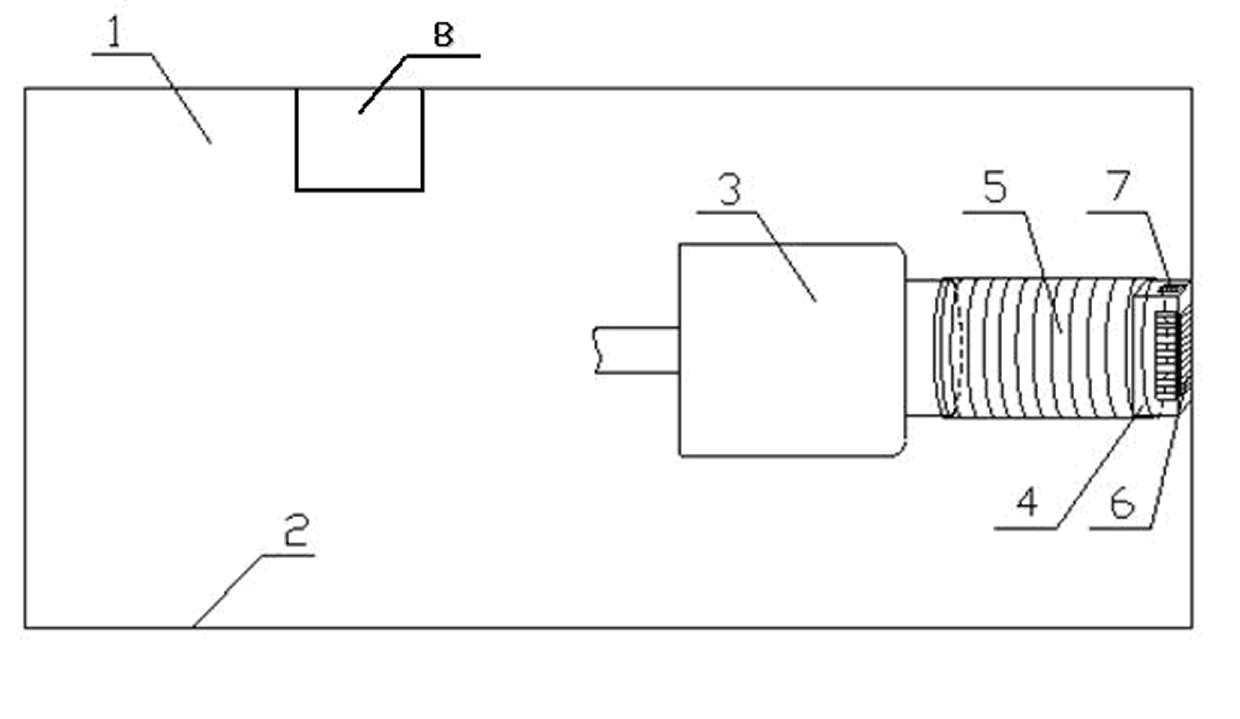

[0014] like figure 1 As shown, a structural schematic diagram of the temperature control system of the wind turbine cabin of the present invention is provided, which mainly includes shutters 4, plastic insulating sleeves 5 and heaters 8, the shutters 4 shown are arranged on the cabin wall 2, and the shutters 4 It is a three-dimensional structure, on which not only the shutters 6 communicating with the outside of the cabin 1 are provided, but also the shutter side windows 7 communicating with the inside of the cabin 1 are provided. The heater 8 is arranged on the cabin wall 2 for heating the cabin 1 . A generator 3 is arranged in the nacelle 1 , and the cooling air outlet of the generator 3 shown communicates with the louver 4 through a plastic insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com