Capacitive touch inductor

A touch sensor, capacitive technology, applied in the field of double-sided projected capacitive touch sensors, can solve the problems of reducing the signal strength of the lower layer sensing unit, affecting the visual effect, reducing the sensitivity, etc., to reduce visual defects, improve signal strength, The effect of increasing the capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

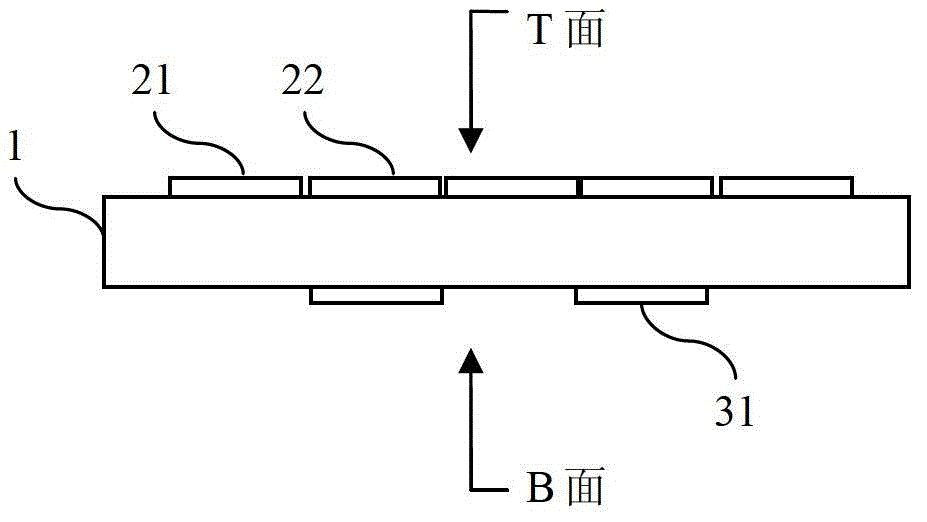

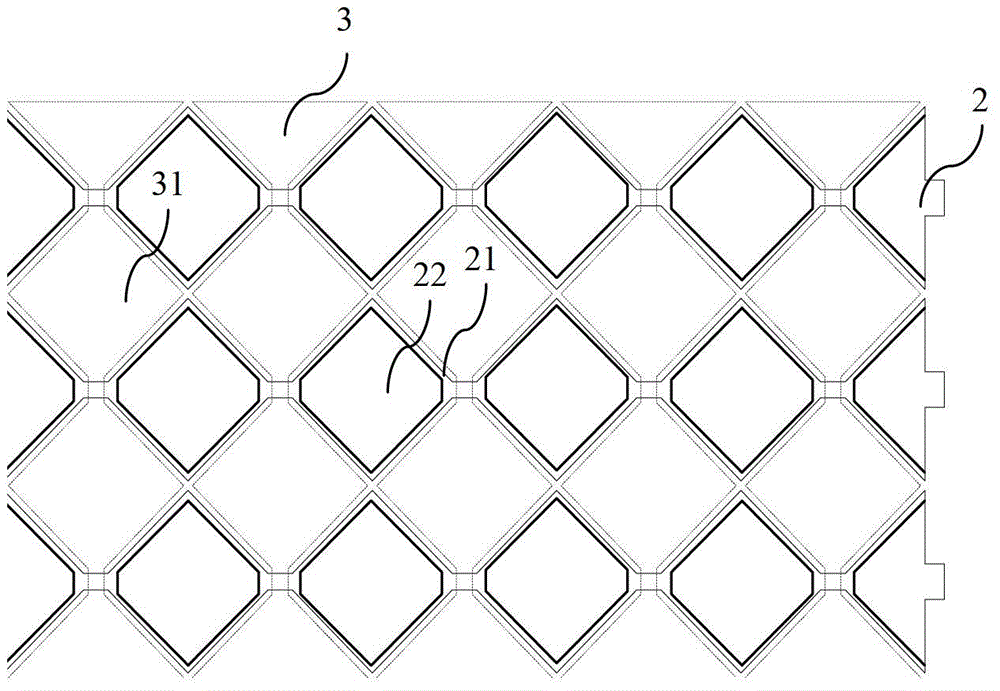

[0029] Such as figure 1 and image 3 The capacitive touch sensor shown includes an insulating substrate 1, a group of first sensing electrodes 2 including an array of first sensing units 21 formed on the upper surface (T surface) of the substrate 1, an array of first auxiliary sensing units 22 and a first 23 groups of induction electrode leads, such as Figure 5 As shown; the second sensing electrode 3 group and the second sensing electrode lead 33 group including the second sensing unit 31 array formed on the lower surface (B surface) of the substrate 1, such as Figure 5 As shown; the first sensing electrode 2 group and the second sensing electrode 3 group are orthogonal to each other; the first sensing unit 21 array and the second sensing unit 31 array are interlaced; the first sensing unit 21 array and the first auxiliary sensing unit 22 The arrays are interlaced and overlapped with the array of the second sensing unit 31; the diagonal length ratio of the first sensing u...

Embodiment 2

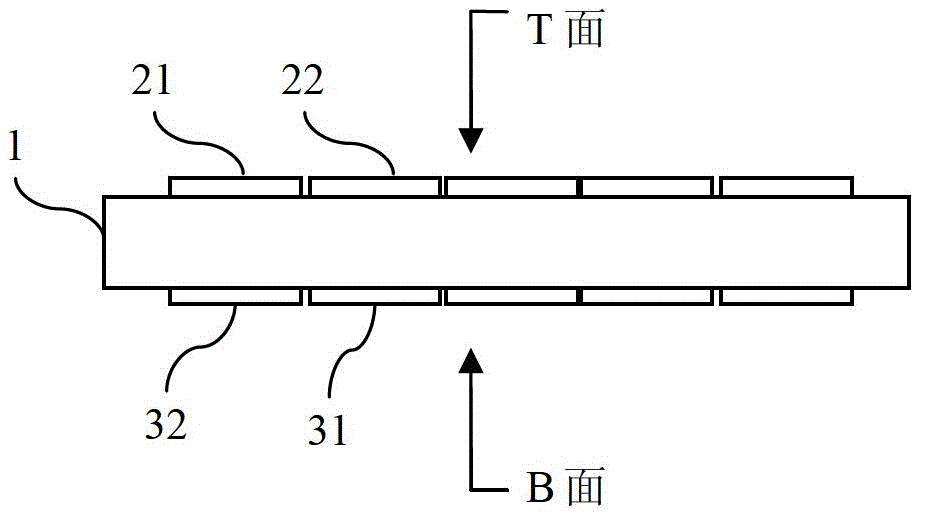

[0031] Such as figure 2 A capacitive touch sensor shown includes an insulating substrate 1, a first sensing electrode 2 group including an array of first sensing units 21 formed on the upper surface (T surface) of the substrate 1, an array of first auxiliary sensing units 22 and a second 23 groups of induction electrode lead wires, such as Figure 5 As shown; the second sensing electrode 3 group including the second sensing unit 31 array, the second auxiliary sensing unit 32 array and the second sensing electrode lead 33 group formed on the lower surface (B surface) of the substrate 1, such as Figure 6 As shown; the first sensing electrode 2 group and the second sensing electrode 3 group are orthogonal to each other; the first sensing unit 21 array and the second sensing unit 31 array are interlaced; the first auxiliary sensing unit 22 and the second auxiliary sensing unit 32 groups are interlaced with each other and overlap with the array of the second sensing unit 31 and ...

Embodiment 3

[0033] In the capacitive touch sensor described in the above-mentioned embodiment 1 or 2, such as Figure 7 As shown, the shapes of the first sensing unit 21 and the second sensing unit 31 are formed by combining and connecting multiple polygons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com