Transparent adhesive sheet for flat panel display

A flat panel display and adhesive sheet technology, applied in the direction of polyether adhesive, adhesive type, film/sheet adhesive, etc., can solve the problems of high light reflection loss and inability to provide visibility, etc. Achieve impact resistance and excellent visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

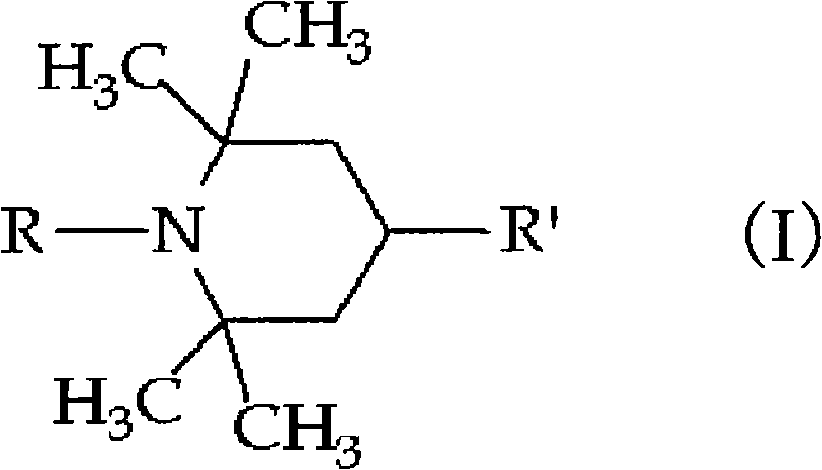

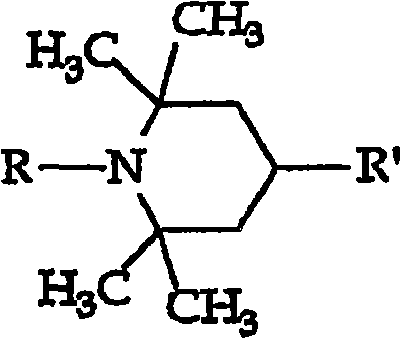

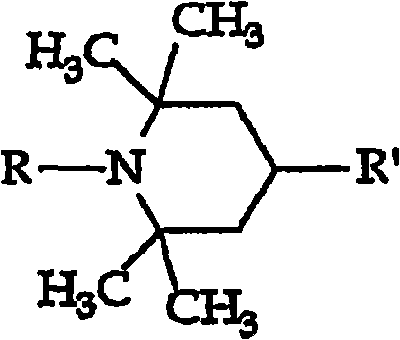

Embodiment 1

[0128] The composition was placed in a stirrer with a vacuum device (Mini Dappo manufactured by SEATEC CORPORATION), and the mixture was stirred in a vacuum (100 Pa) for 1 hour to defoam, said composition comprising the following components: Component A in the specification is a polyoxyalkylene-based polymer (number-average molecular weight: about 20,000), and component B is a hydrosilyl compound (in an amount to provide a functional group ratio (molar ratio) of 0.75) (which is relative to the component The amount of the hydrosilyl group of the polyoxyalkylene polymer of the component A)), and the component C is the hydrosilylation catalyst (0.9×10 -3 mol, per 1 mol of the alkenyl group in component A) (manufactured by KANEKA Corporation), and 0.1 wt% of bis(1,2,2,6,6- Pentamethyl-4-piperidinyl) sebacate (Tinuvin 765 (trade name) manufactured by Ciba Specialty Chemicals). Then, the vacuum defoaming composition was applied (cast) at room temperature on a base separator (suppor...

Embodiment 2、3

[0130] A transparent adhesive sheet was prepared in the same manner as in Example 1 except that the thickness of the applied composition was changed to 150 μm and 250 μm.

Embodiment 4-6

[0132] A transparent adhesive sheet (Example 4) was prepared in the same manner as in Example 1 except that the amount of the added light stabilizer (Tinuvin 765) was changed to 0.6% by weight relative to Component A, and further, the applied The thickness of the coated composition was changed to 150 μm and 250 μm to prepare transparent adhesive sheets (Examples 5 and 6, respectively).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com