Filling template bracket

A formwork and filling pipe technology, which is applied to filling materials, mine roof brackets, safety devices, etc., can solve problems that affect the efficiency and quality of filling operations, poor connection of baffles, and extrusion across formwork, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

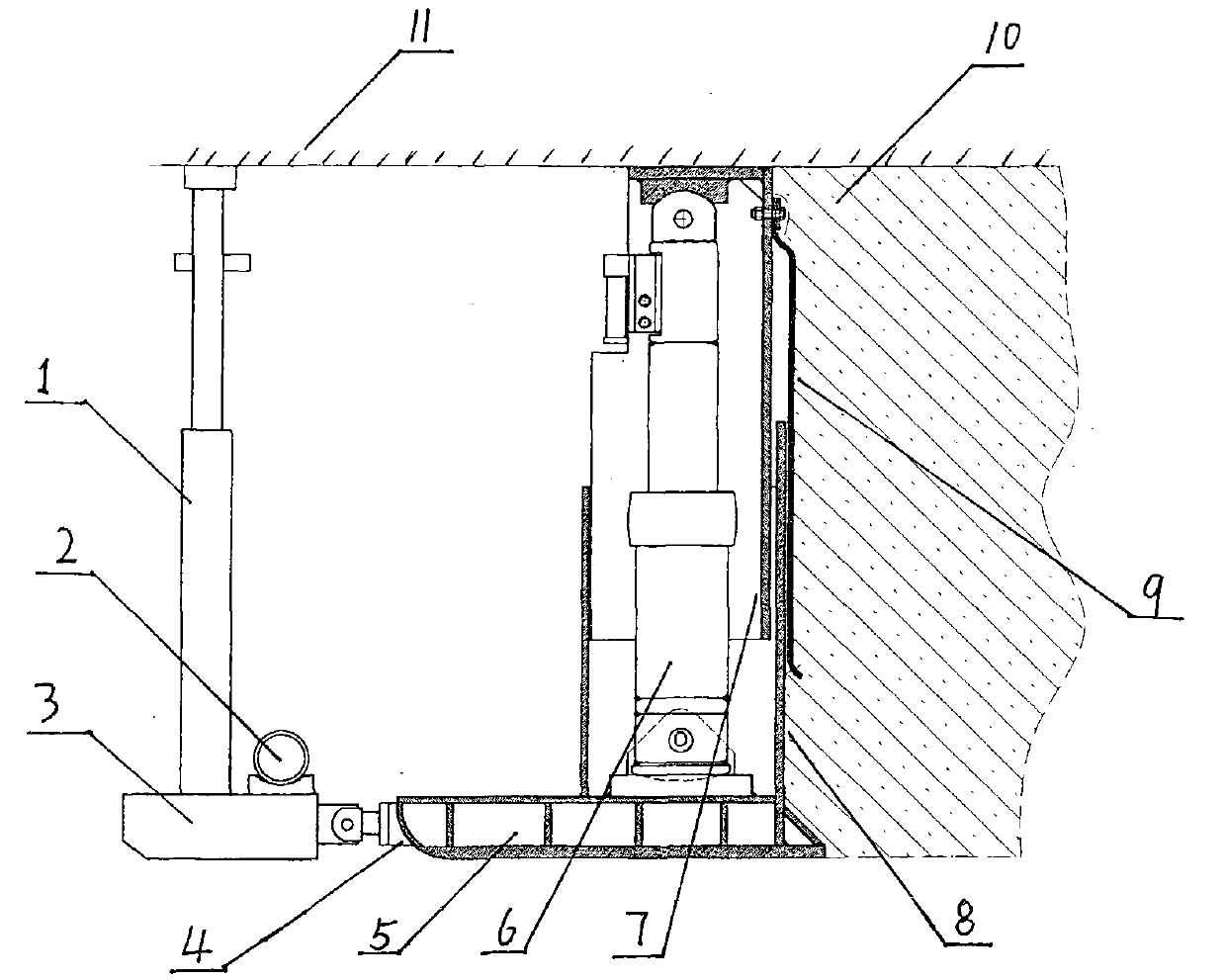

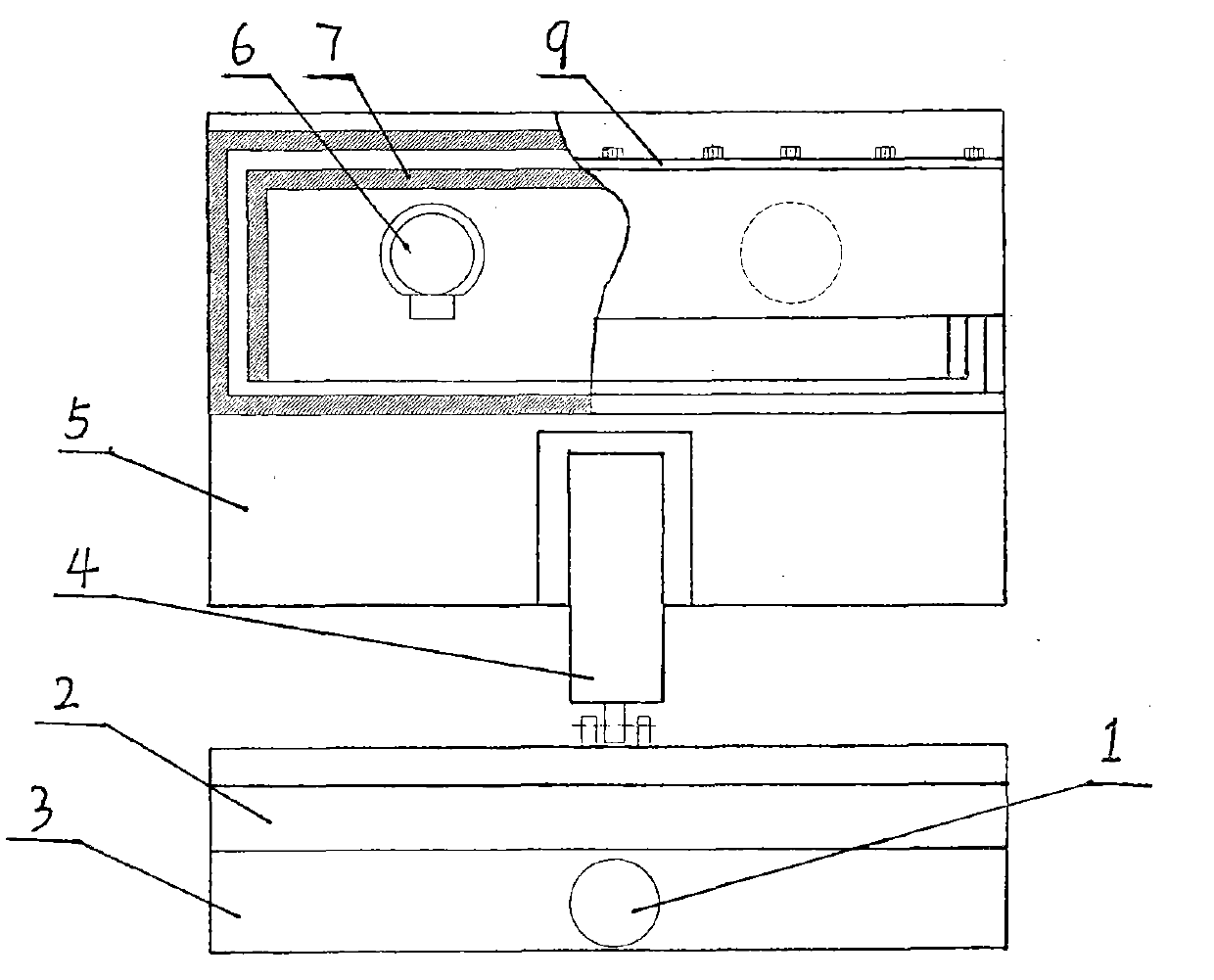

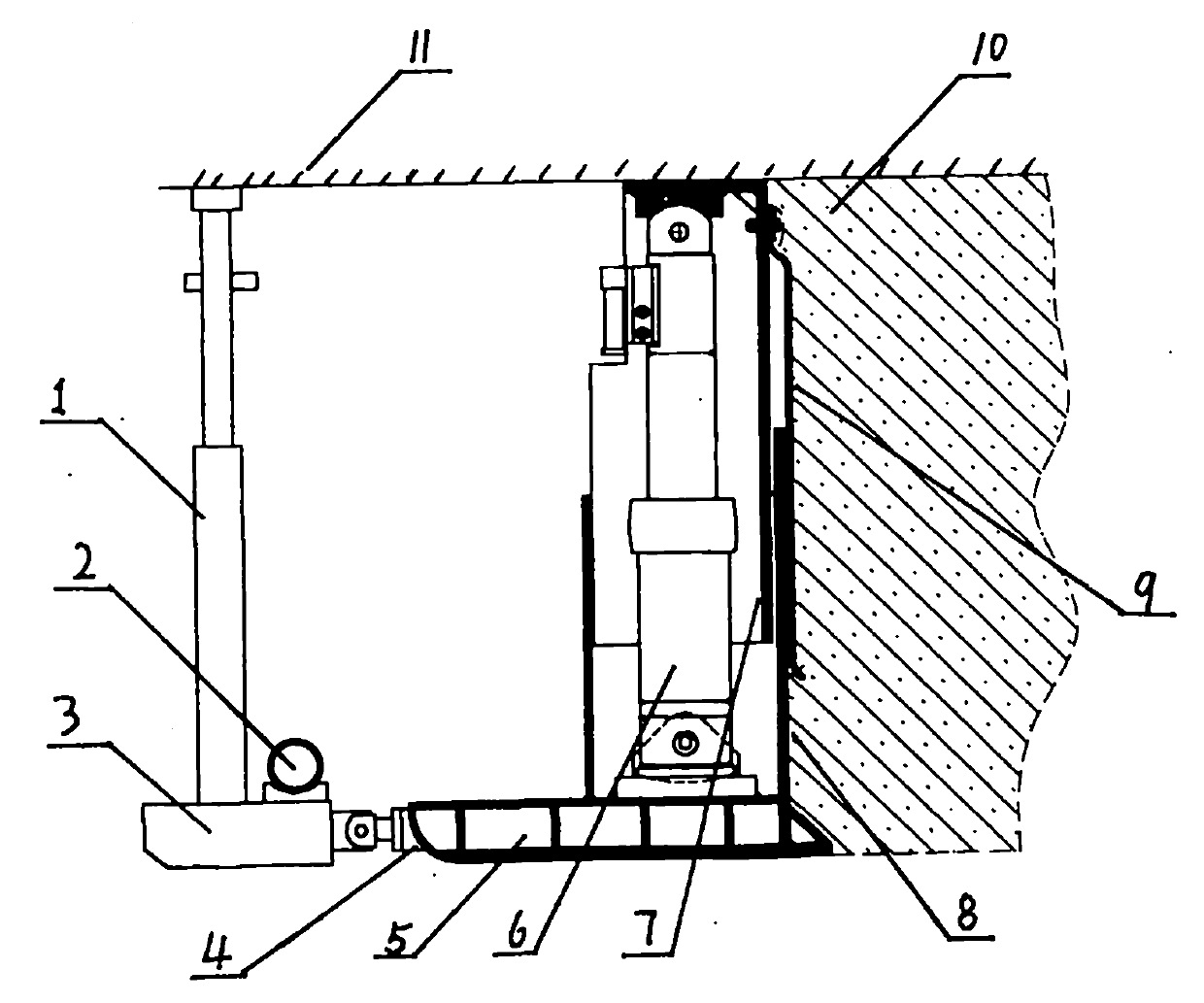

[0009] Depend on figure 1 , figure 2 It can be seen that the present invention includes: a single hydraulic prop 1 , a filling pipe 2 , a base 3 , a pushing hydraulic cylinder 4 , a bottom support 5 , a hydraulic upright 6 , an adjustment frame 7 , and a sealing rubber plate 9 . Two hydraulic uprights 6 are arranged symmetrically on both sides in the bottom bracket 5 frame, the bottom of the hydraulic uprights and the bottom bracket are connected by pins, and the bottom bracket is made of rectangular steel. A pushing hydraulic cylinder 4 is set at the middle horizontal position of the bottom bracket 5, the bottom of the pushing hydraulic cylinder 4 is connected and fixed with the bottom bracket, the piston head of the pushing hydraulic cylinder is connected with the base 3, and a single hydraulic cylinder is vertically set The pillar 1 is provided with a filling pipe 2 on the bottom side of the single hydraulic pillar, the base is a rectangular metal structure, and the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com