Groove type solar-powered atomization flash evaporation thermal generating set

A trough-type solar energy and thermal power generation technology, which is applied in solar thermal power generation, mechanical power generated by solar energy, machines/engines, etc., can solve the problems of difficult control of instantaneous pressure and uneven vaporization pressure, and reduce heat exchange loss and improve The effect of power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

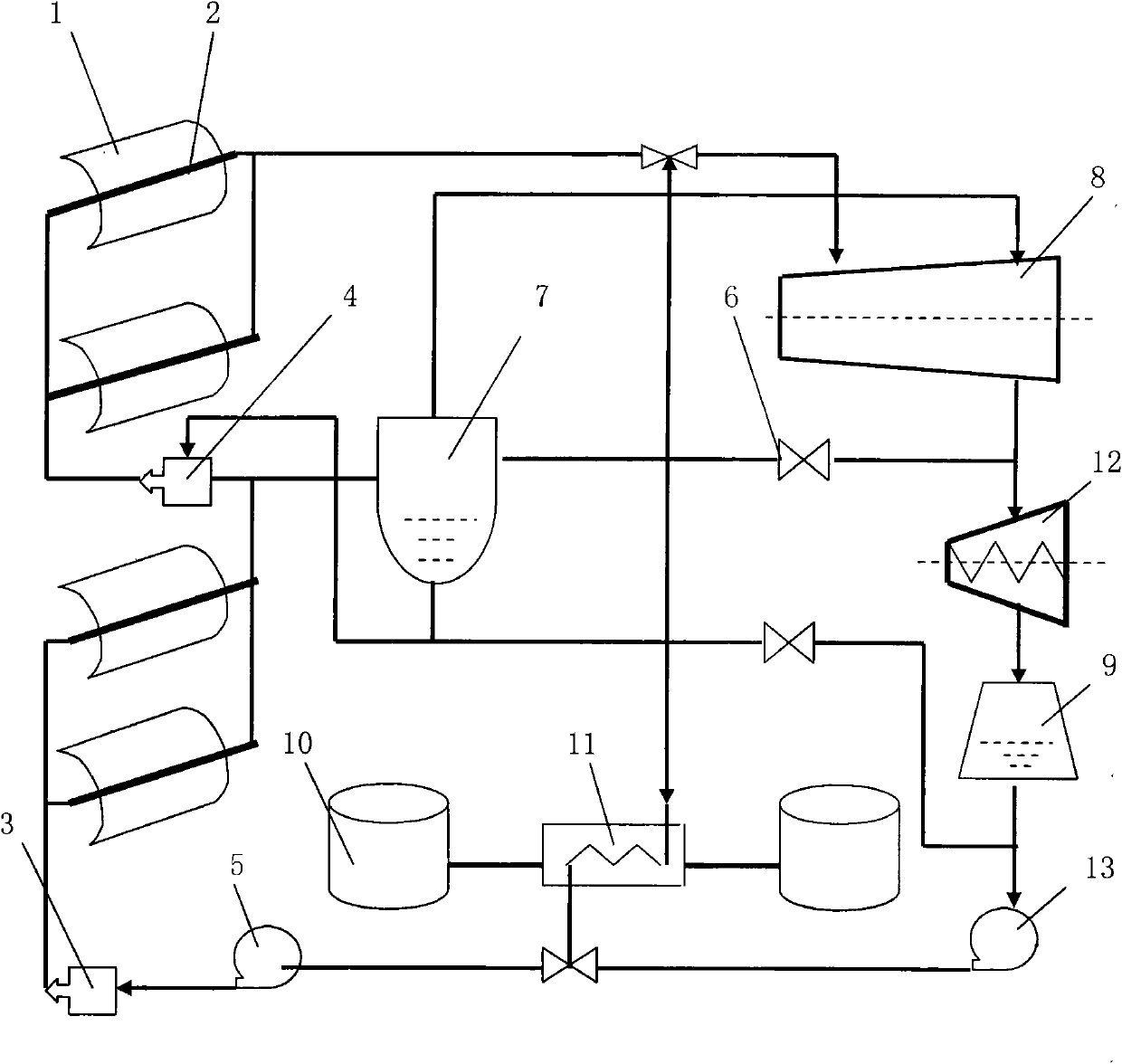

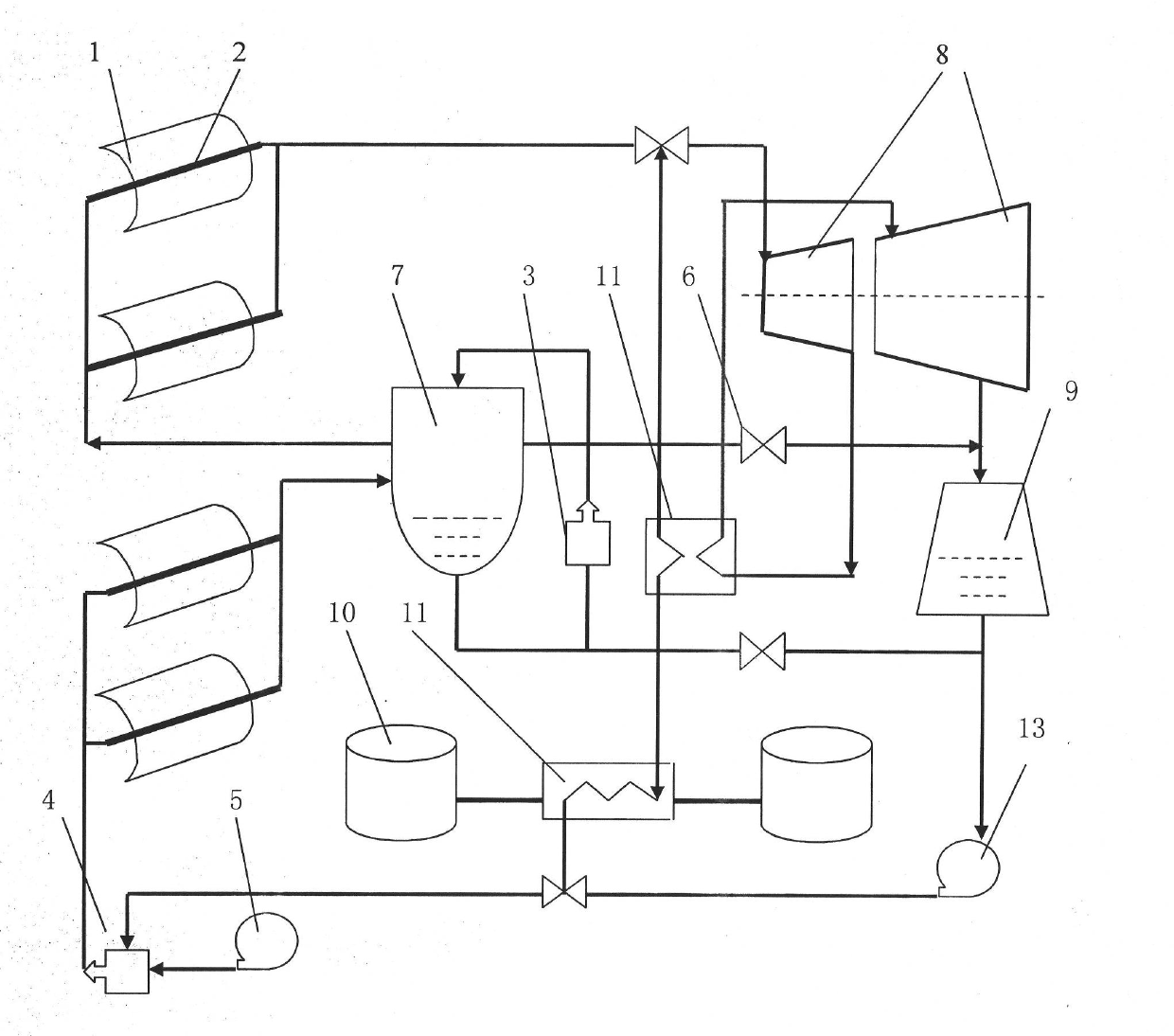

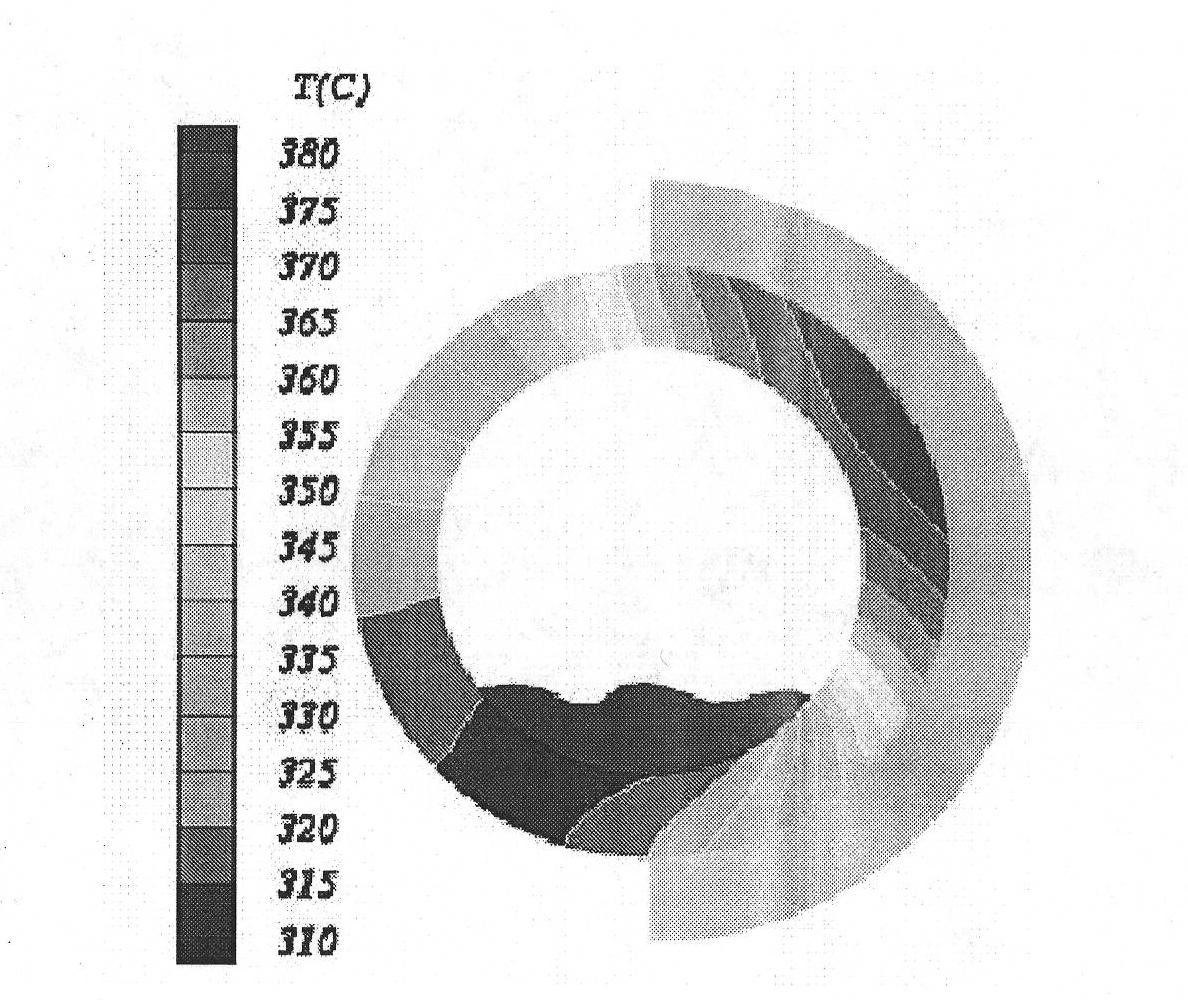

[0029] 1. Replace the heat collector tube used in the trough solar thermal power generation device with the line-focused enhanced heat-collector tube (2) of the annular wave node or the helical wave-node metal inner tube with enhanced heat transfer function, and give full play to the line-focused enhanced heat collector tube ( 2) For the disturbance effect of the heat transfer working medium, the laminar flow heating is changed to the eddy current heating.

[0030] 2. Use atomized gas instead of heat transfer oil or water as heat transfer medium. In order to inherit the advantages of DSG technology and overcome the shortcomings of directly heating the water working medium, atomization devices such as vaporization tank (3) or jet pump (4) are selectively added to the working fluid inlet of the parabolic trough heat collecting device and the light collecting array, These devices are used to generate atomized water vapor, and the "steam" gas is used to complete heat transfer.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com