Piston pump and hydraulic device of vehicle brake system, and vehicle brake system

A technology of vehicle brakes and hydraulic devices, which is applied to components, brakes, pumps, etc. of pumping devices for elastic fluids, and can solve problems such as piston pump function damage, heat load applied to seals, seal damage, etc., to achieve Anti-wear phenomenon, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

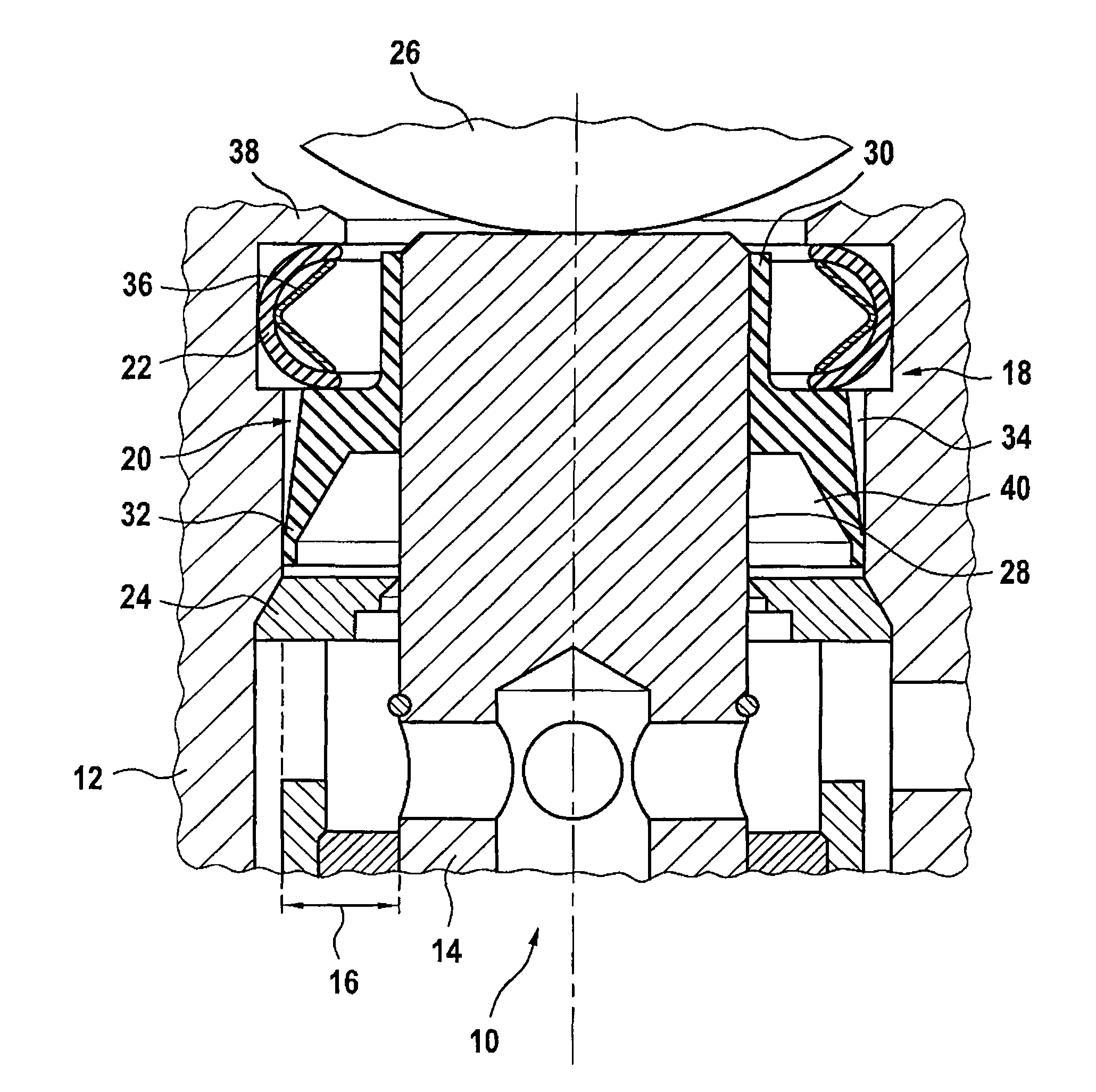

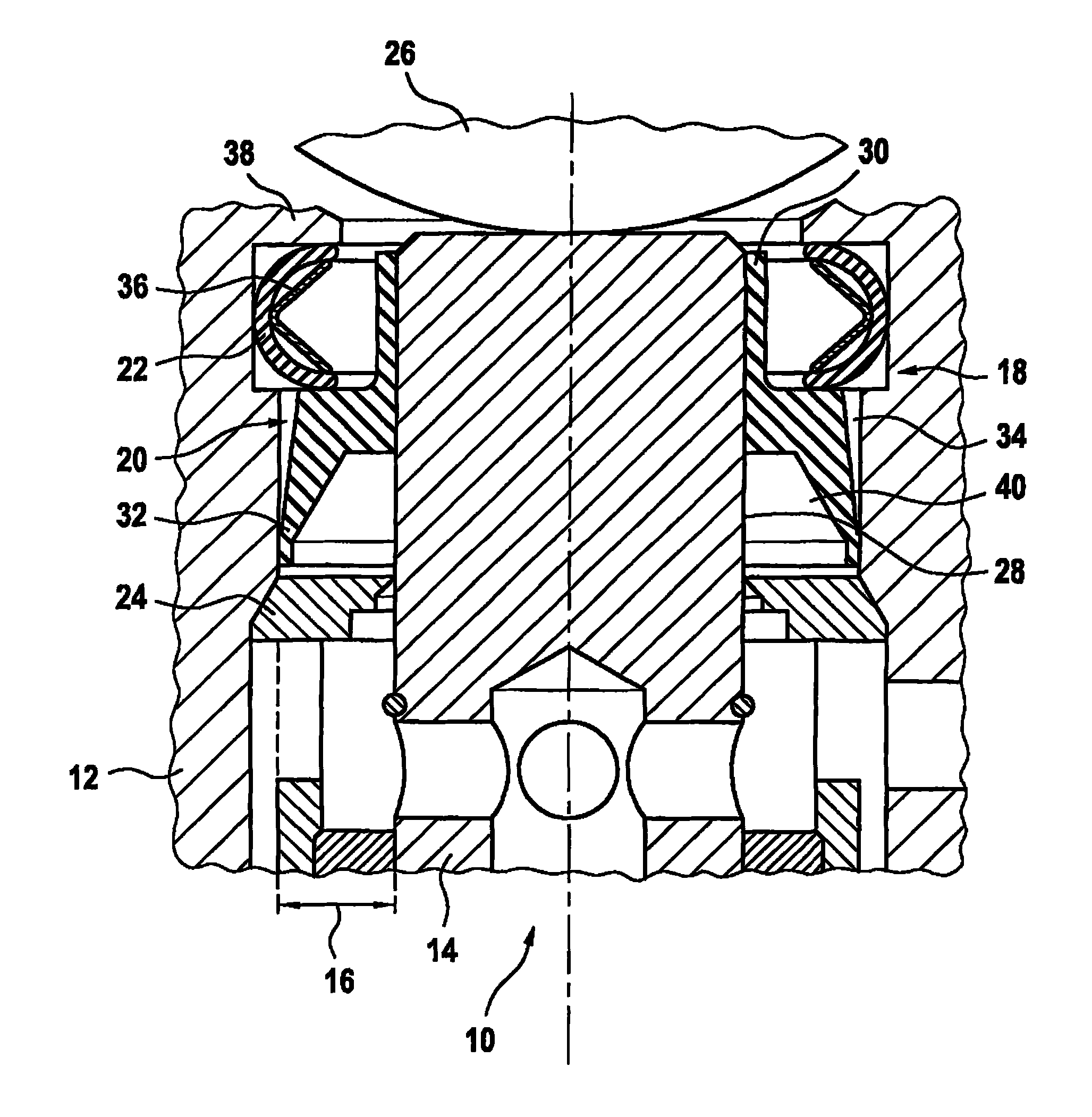

[0026] The drawing shows a piston pump 10 which comprises a housing or cylinder 12 and a piston 14 mounted displaceably in the housing or cylinder. There is a gap 16 between the pump cylinder 12 and the piston 14 . This gap 16 is closed in a fluid-tight manner by means of a sealing device 18 . The sealing device 18 comprises a high-pressure seal 20 and a low-pressure seal 22 as sealing elements. The sliding movement of the piston 14 is substantially guided by a guide ring 24 .

[0027] During operation, the piston 14 is driven by an eccentric 26 . For this purpose, the eccentric 26 therefore presses against an end face of the piston 14 , thereby pushing the piston axially into the housing bore or the pump cylinder 12 and thus carrying out the delivery stroke. For the suction stroke following the delivery stroke, the piston 14 is pushed axially out of the pump cylinder 12 by the spring force of a spring (not shown). As a result, the fluid to be delivered, in the exemplary e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com