Pneumatic tire

A technology for pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, rolling resistance optimization, etc., to reduce rolling resistance, ensure wear resistance, and improve drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

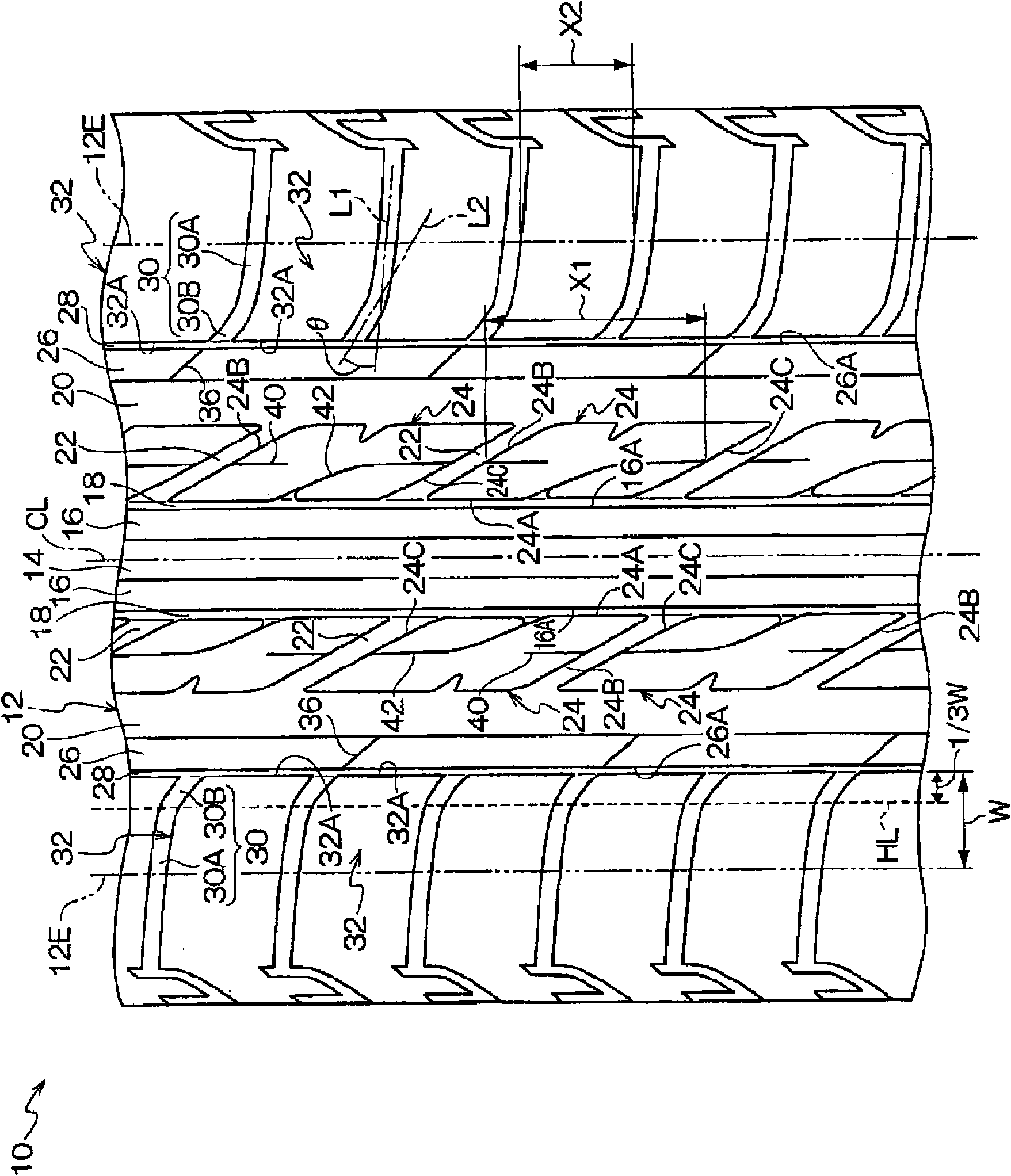

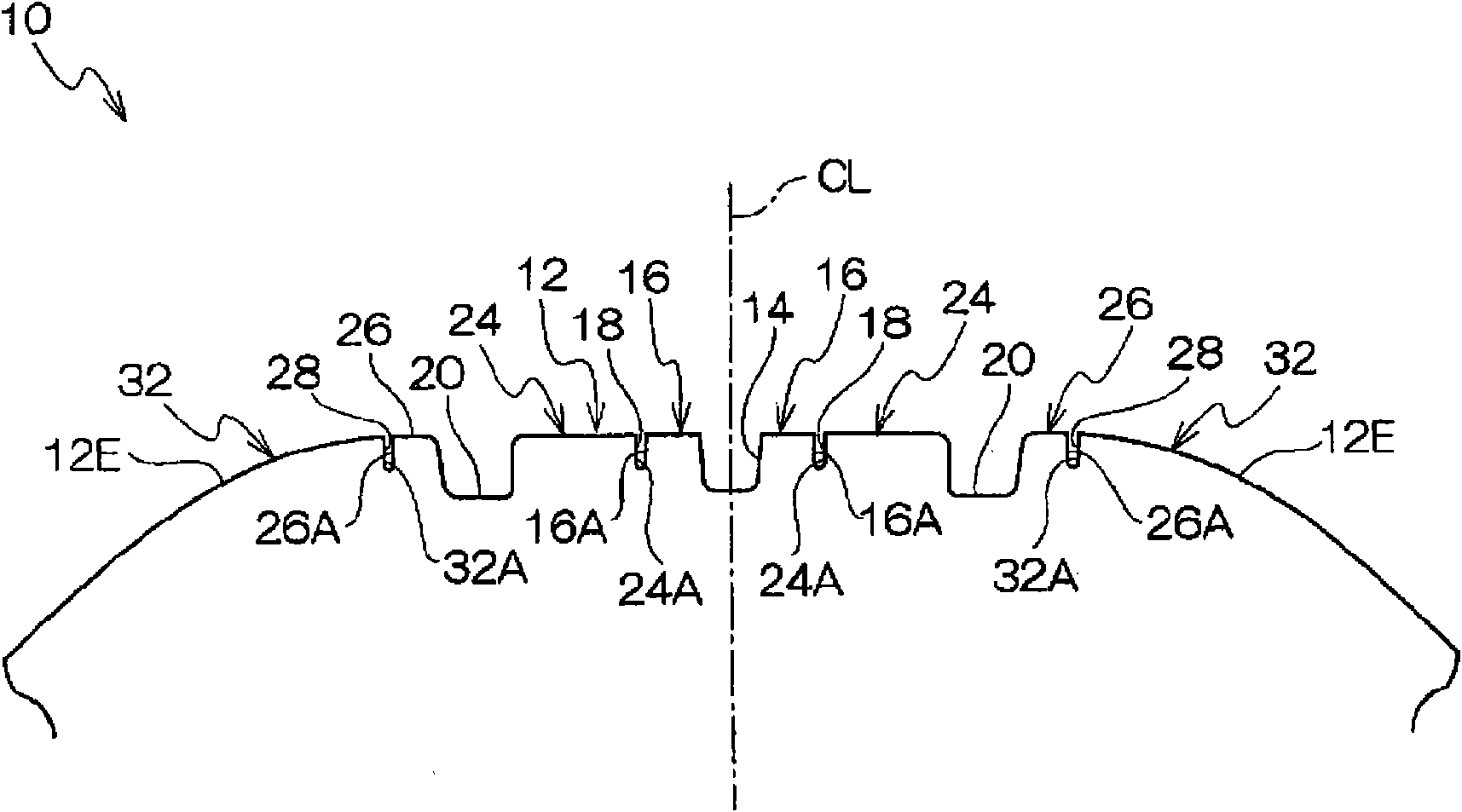

[0049] In the first embodiment, the tire circumferentially extending portion of the second sipe 42 formed on the center block 24 is on the same straight line as the first sipe 40 , but the present invention is not necessarily limited to In this structure, the first sipe 40 and the second sipe 42 may be shifted in the tire width direction, or a structure in which a plurality of first sipes 40 are formed on the center block 24 may be used.

[0050] In the above-mentioned embodiment, the first sipe 40 and the second sipe 42 have the same depth structure, but the present invention is not necessarily limited to this structure, and the first sipe 40 and the second sipe 42 may have the same depth. 42 is not the same depth.

[0051] In the above-mentioned embodiment, the first sipe 40 and the second sipe 42 are formed on the center block 24. However, the present invention is not necessarily limited to this structure. The first sipe 40 and the second sipe 42 are formed on the block 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com