Optical lens

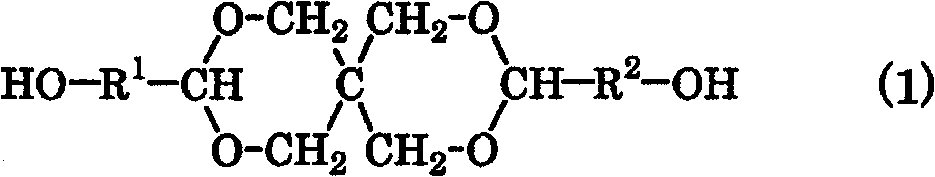

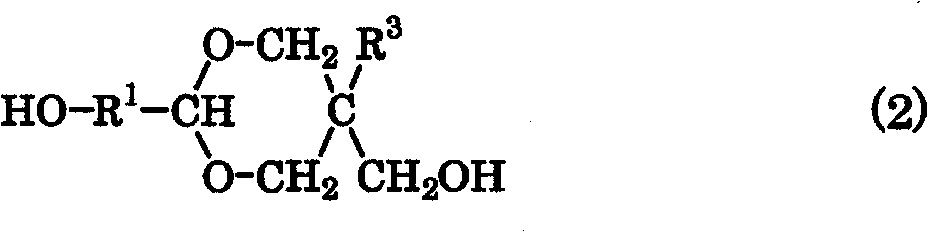

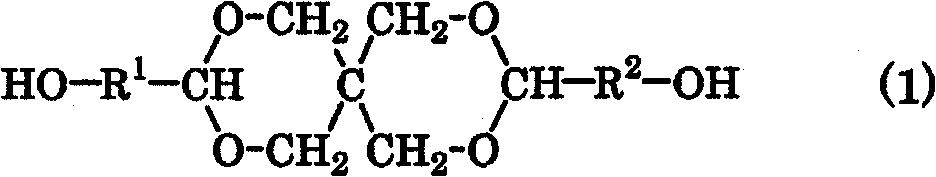

一种光学透镜、二醇的技术,应用在光学、光学元件、仪器等方向,能够解决低阿贝数、污染模具、着色增加等问题,达到低阿贝数、生产率高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5、 comparative example 1、2

[0074] 〔Manufacture and evaluation of polyester resins〕

[0075] In the 0.15 cubic meter polyester manufacturing device equipped with a packed column rectification tower, a splitter, a full shrinker, a cooling tank, a stirrer, a heating device, and a nitrogen introduction pipe, add the raw material monomers listed in Table 1 and 2, In the presence of 0.03 mol % of manganese acetate tetrahydrate with respect to the dicarboxylic acid component, the temperature was raised to 215° C. under a nitrogen atmosphere, and transesterification was performed. After the reaction conversion rate of the dicarboxylic acid component is above 90%, add 0.02 mol% of antimony (III) oxide and 0.06 mol% of triethyl phosphate to the dicarboxylic acid component. Polycondensation is carried out below kPa. The reaction is terminated when an appropriate melt viscosity is reached to produce a polyester resin.

[0076] The evaluation results are shown in Tables 1 and 2.

[0077] In addition, the meanings...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap