Double-cage harvester for cyperus esculentus

A kind of oily bean and harvester technology, applied in the direction of digging harvester, harvester, excavator, etc., can solve the problem of separation of oily bean and soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

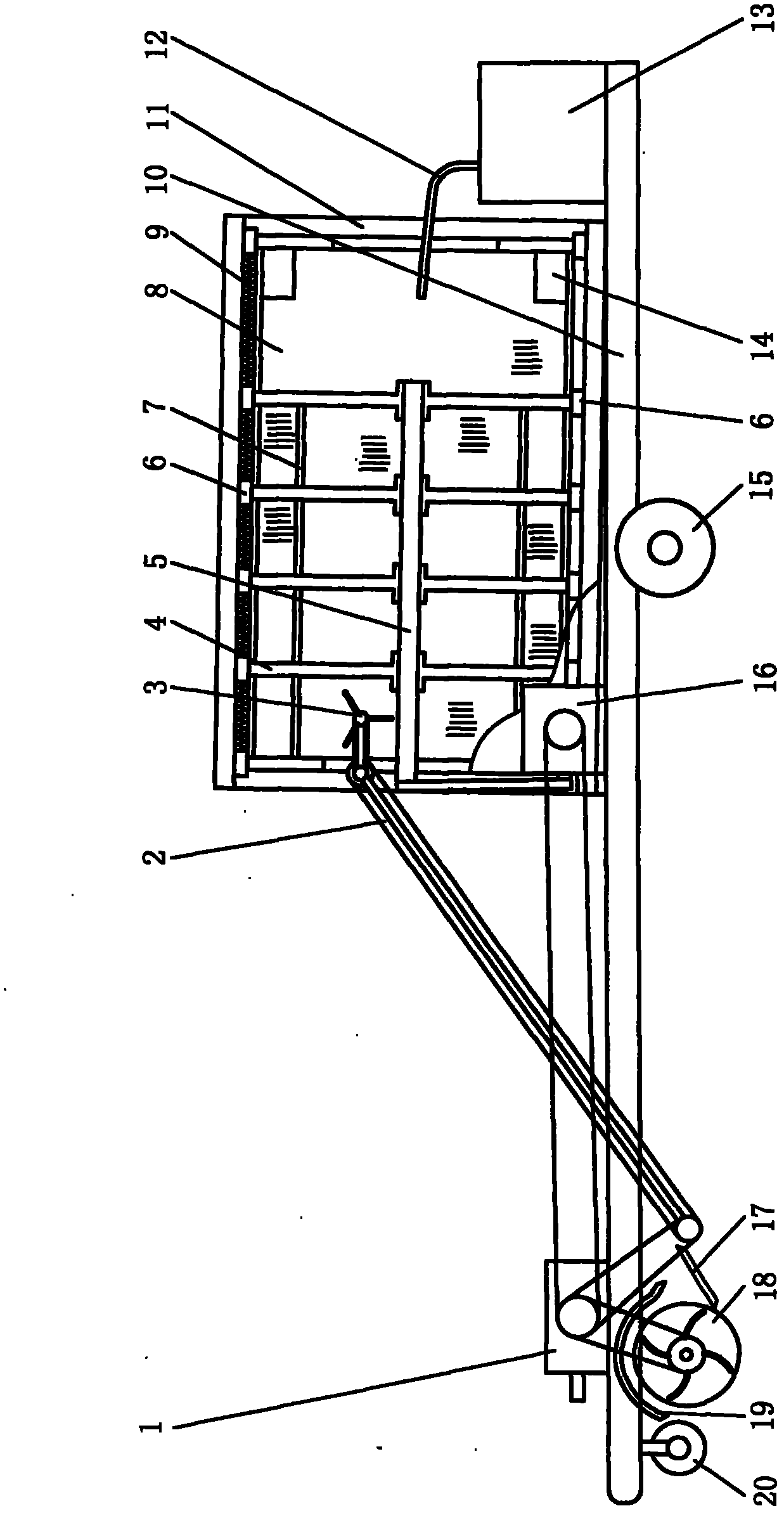

Embodiment 1

[0011] The double-cage oil sand bean harvester is composed of a fixed depth wheel 20, a rotary harrow 18, a shovel plate 17, a conveyor belt 2, a material distribution wheel 3, a sieve cage, a collection box 13, a sieve cage frame 11, and a frame 10. , wheels 15 and a gearbox; the fixed depth wheel 20 is installed under the front of the frame 10; the shovel plate 17 is installed at the front position below the frame 10; The front portion of the soil plate 17, behind the depth-fixing wheel 20, the soil retaining plate 19 is installed on the rotary harrow 18; Cage; the screen cage is installed in the screen cage frame 11 through the rollers 6, and the soil brush 9 is installed on the upper part thereof, and the screen cage frame 11 is installed above the rear part of the frame 10; the collection box 13 is mounted on the frame 10 and is located on the screen The rear part of the cage, the upper part of the collection box 13 is equipped with a material guide plate 12, and the fron...

Embodiment 2

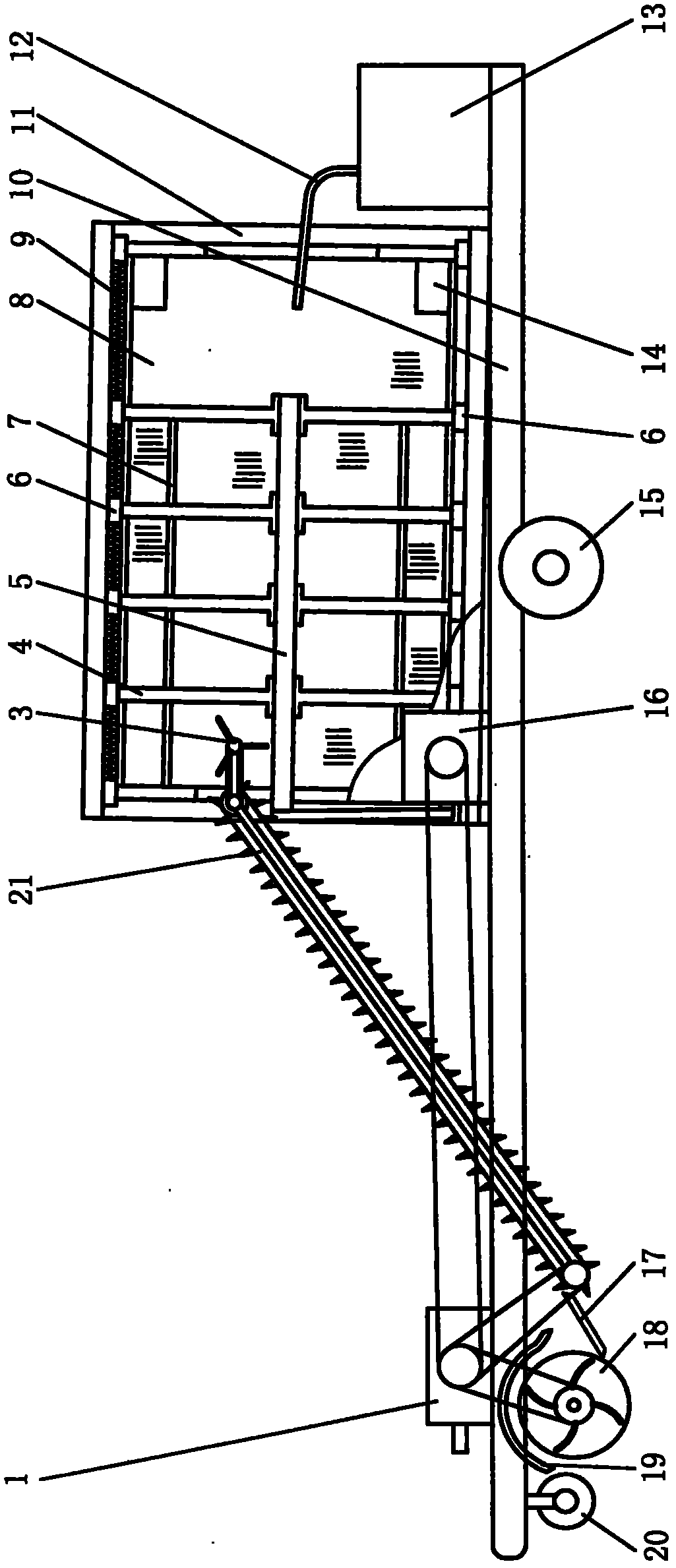

[0013] The conveyor belt 2 in the embodiment 1 adopts the bucket type conveyor belt 21 and is installed obliquely.

Embodiment 3

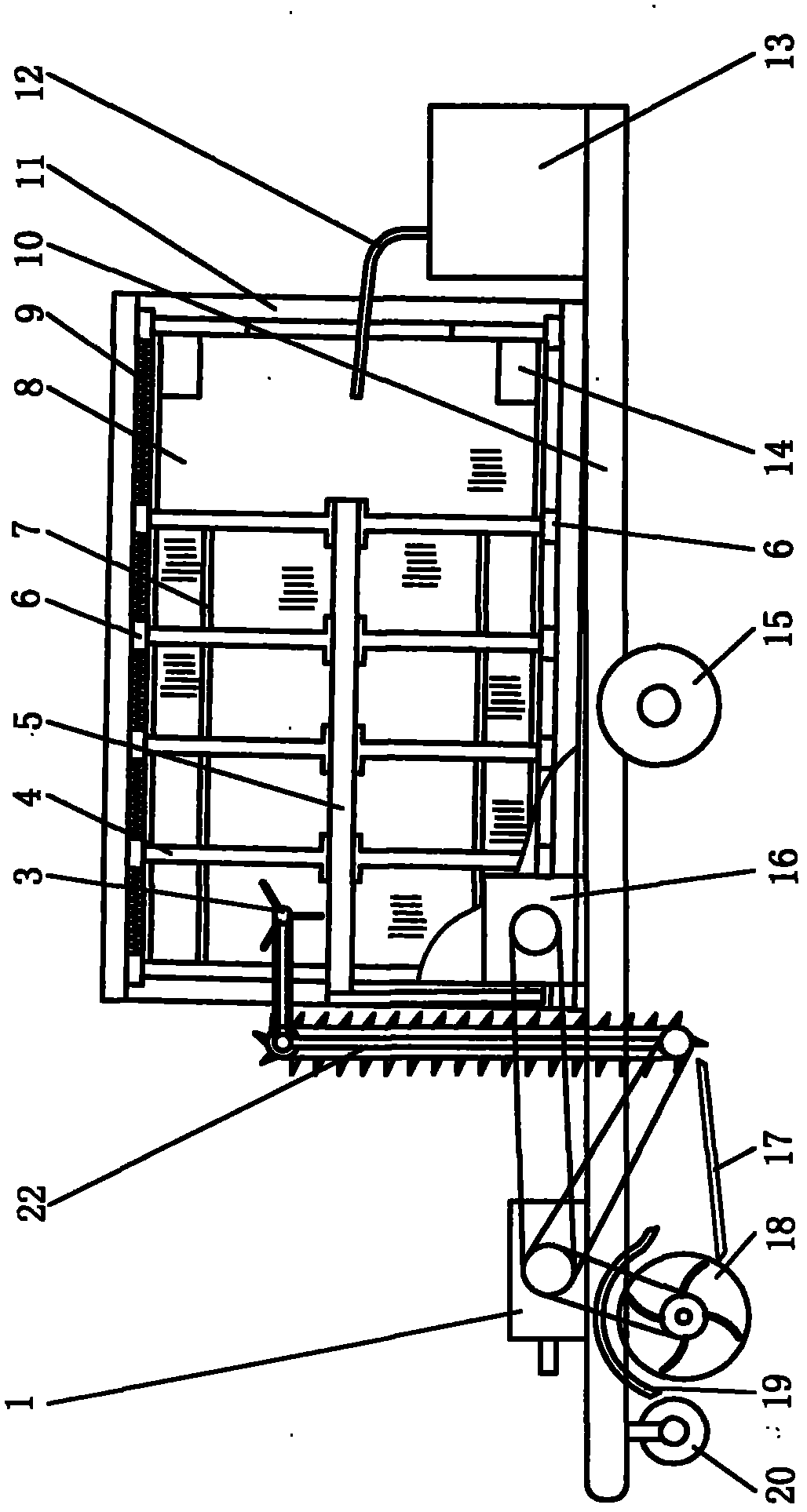

[0015] The conveyor belt 2 in the embodiment 1 adopts the bucket type conveyor belt 22 and is installed vertically.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com