Spherical rapid hydraulic fire hydrant and working method thereof

A fire hydrant and fast technology, applied in fire rescue and other directions, can solve the problems of delayed fire extinguishing time, high labor intensity, difficulty in closing valves, etc., and achieve the effects of stable quality, simple structure and light overall weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

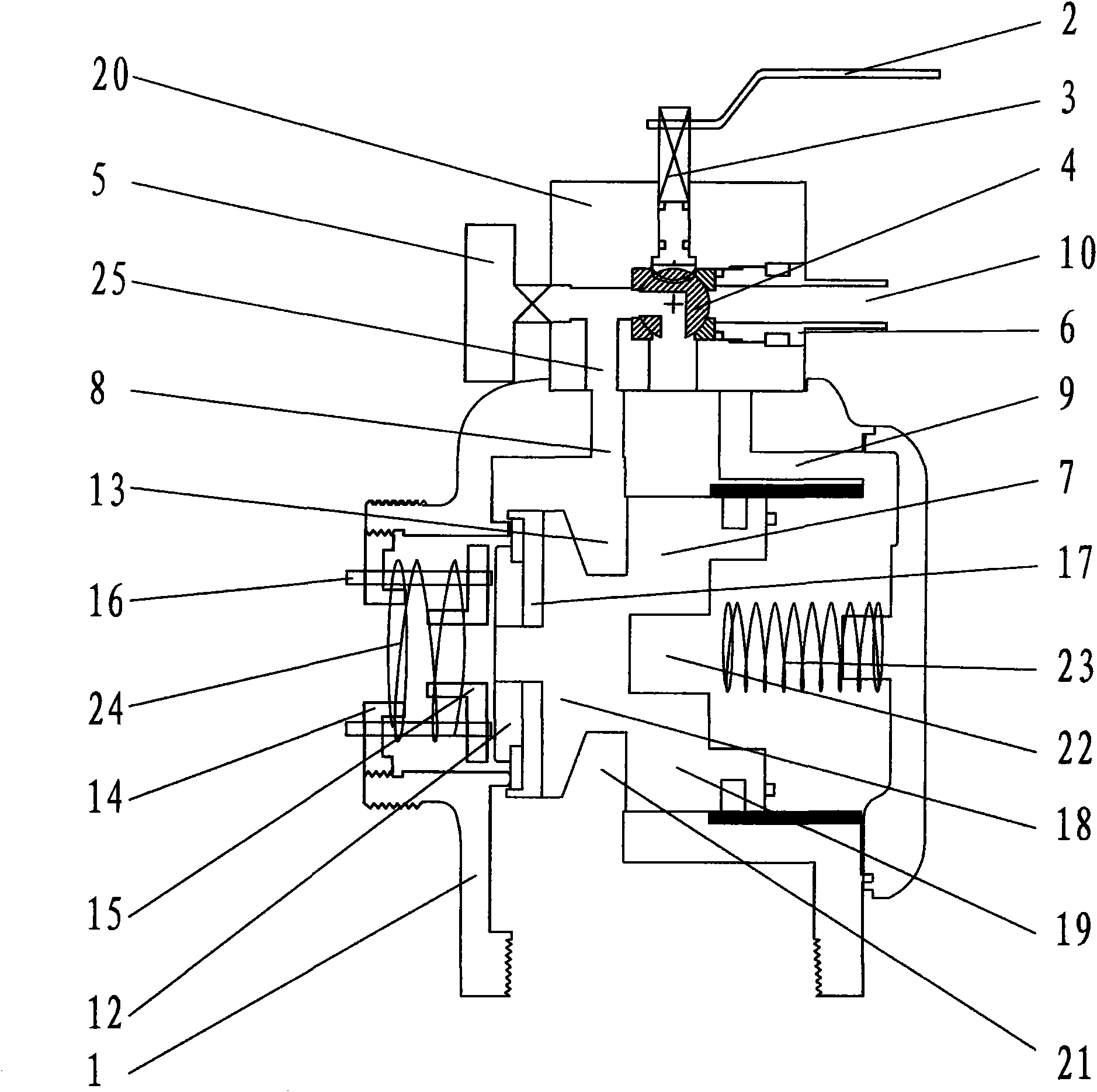

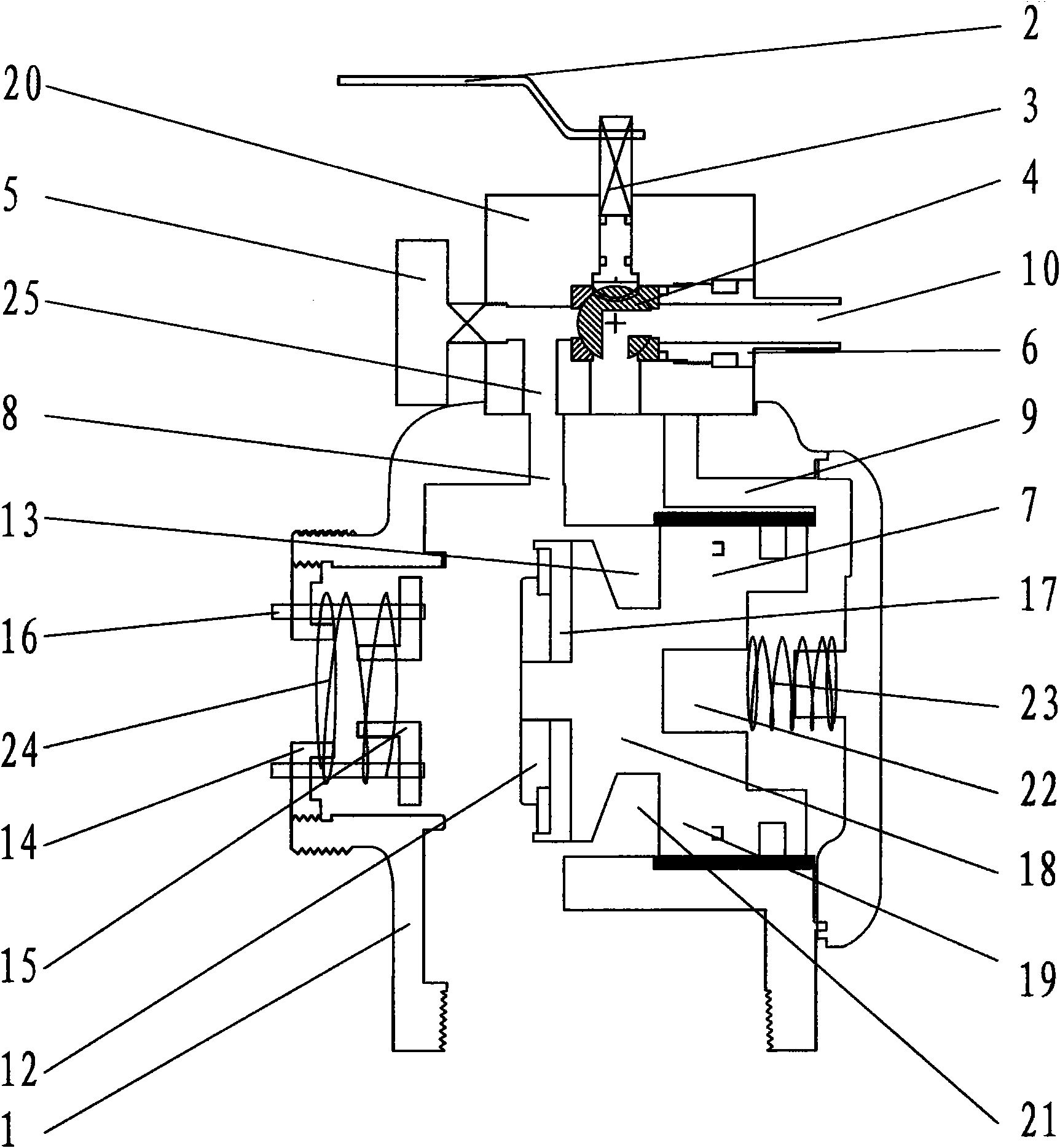

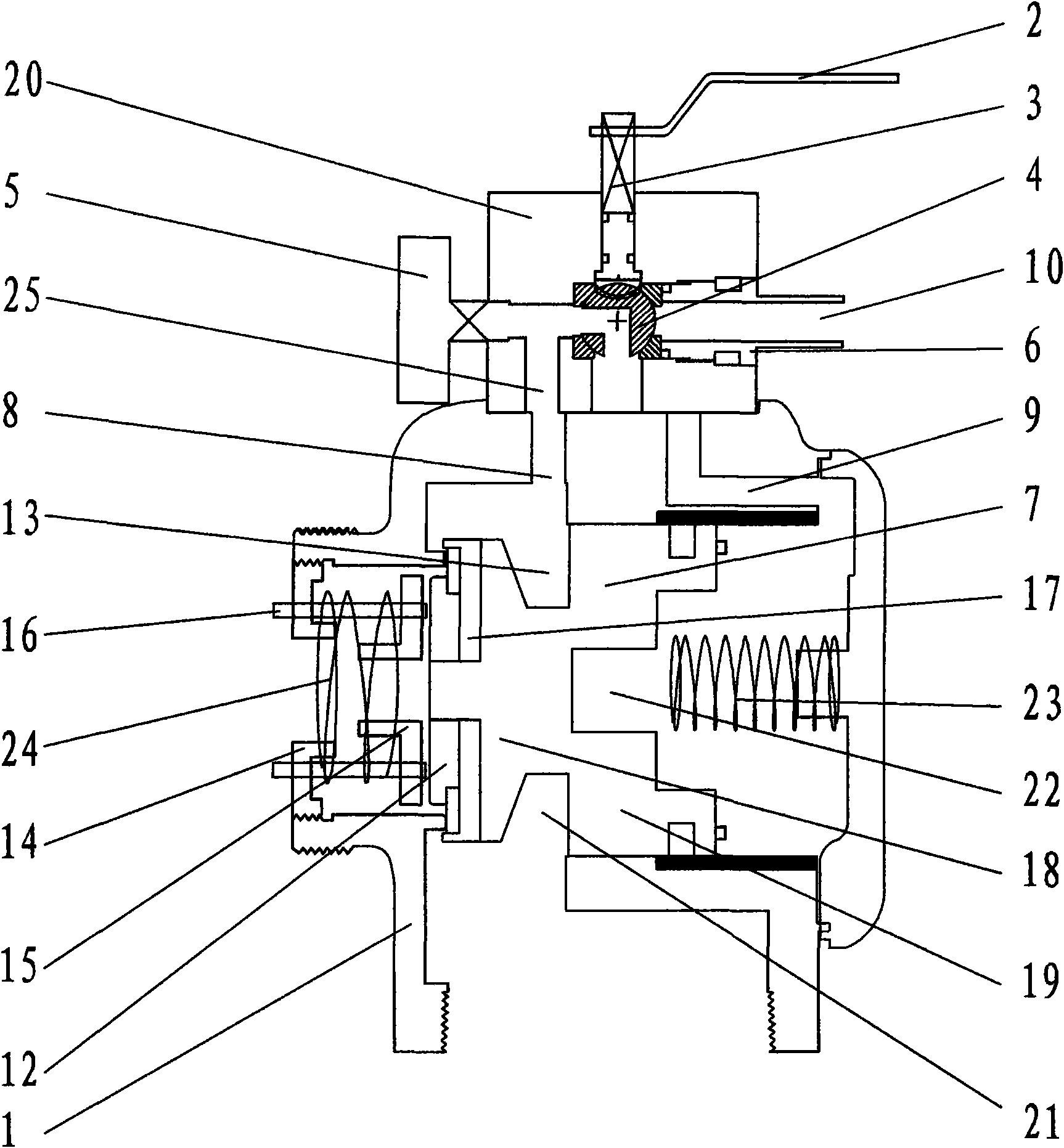

[0027] Embodiments of the present invention will be specifically described below with reference to the drawings.

[0028] A spherical rapid hydraulic indoor fire hydrant, comprising a housing 1 with a cavity, and a movable valve core 7 inside the housing 1, the valve core 7 divides the cavity in the housing 1 into a first channel 8 and a second channel 8. Channel 9, the housing is respectively provided with connected water inlets and water outlets, the water outlet port is provided with an interface for matching connection with the fire hose, the upper end of the housing 1 is also equipped with a valve body, the valve body includes There are bonnet 20, valve stem 3, steel ball 4, handle 2, bonnet 20 and shell 1 are fixedly installed, and bonnet 20 is provided with liquid flow chamber 25, and liquid flow chamber 25 is connected with the first channel 8 and the second channel 9, the valve cover 20 is also provided with a third channel 10 communicating with the liquid flow chambe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap