Automatic continuous filter

A filter and automatic technology, applied in the direction of fixed filter element filters, filtration separation, instruments, etc., can solve the problems of low work efficiency and poor continuity of filtration operations, and achieve good automatic performance, high continuity, and large filtration capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

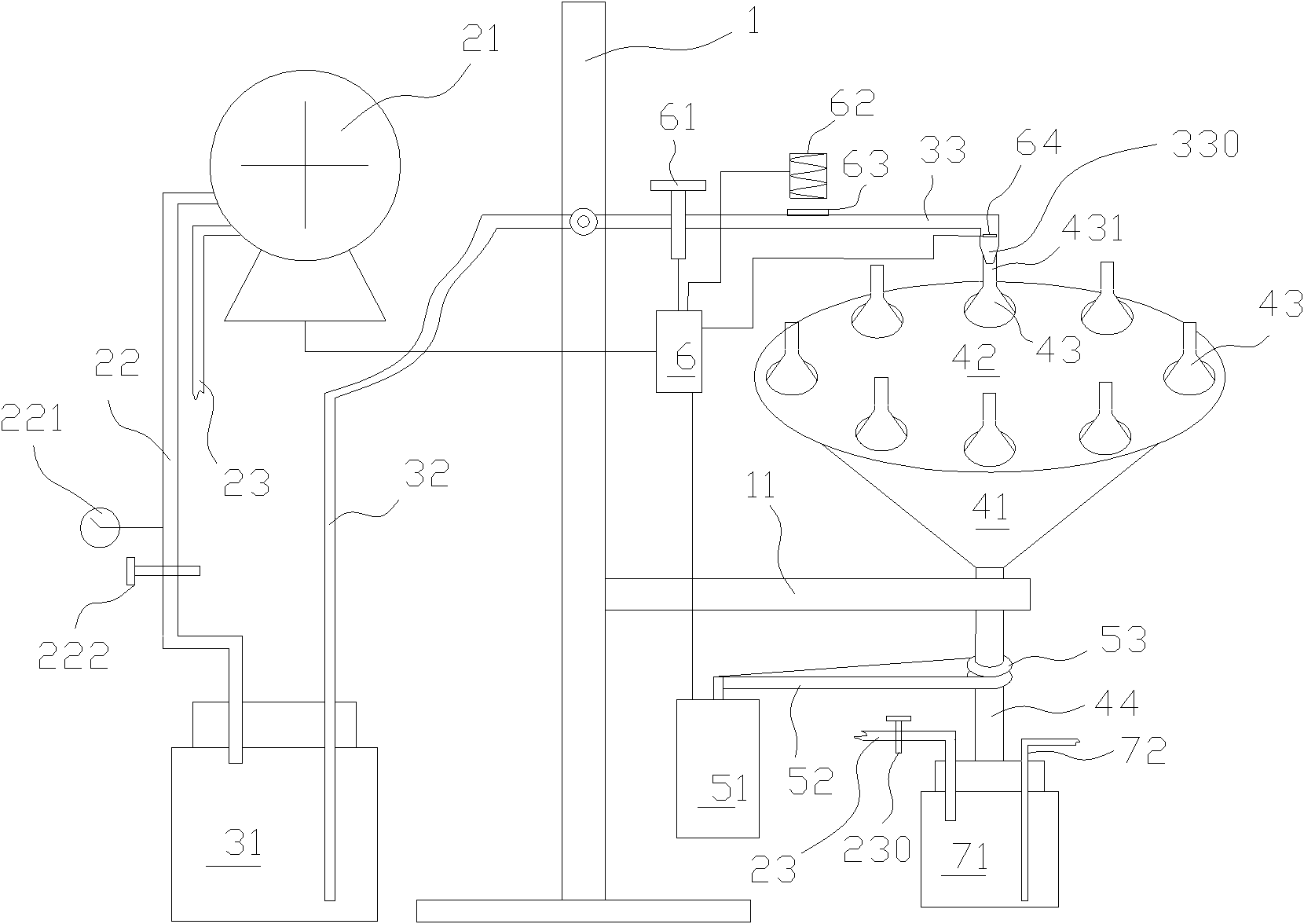

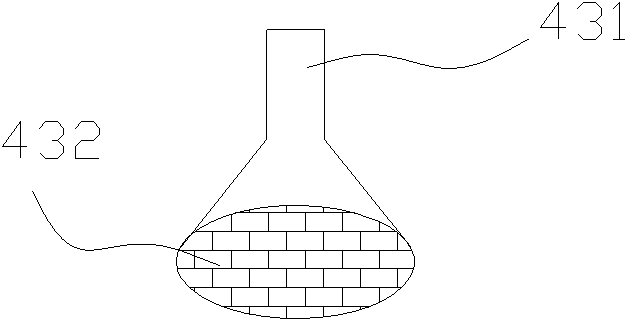

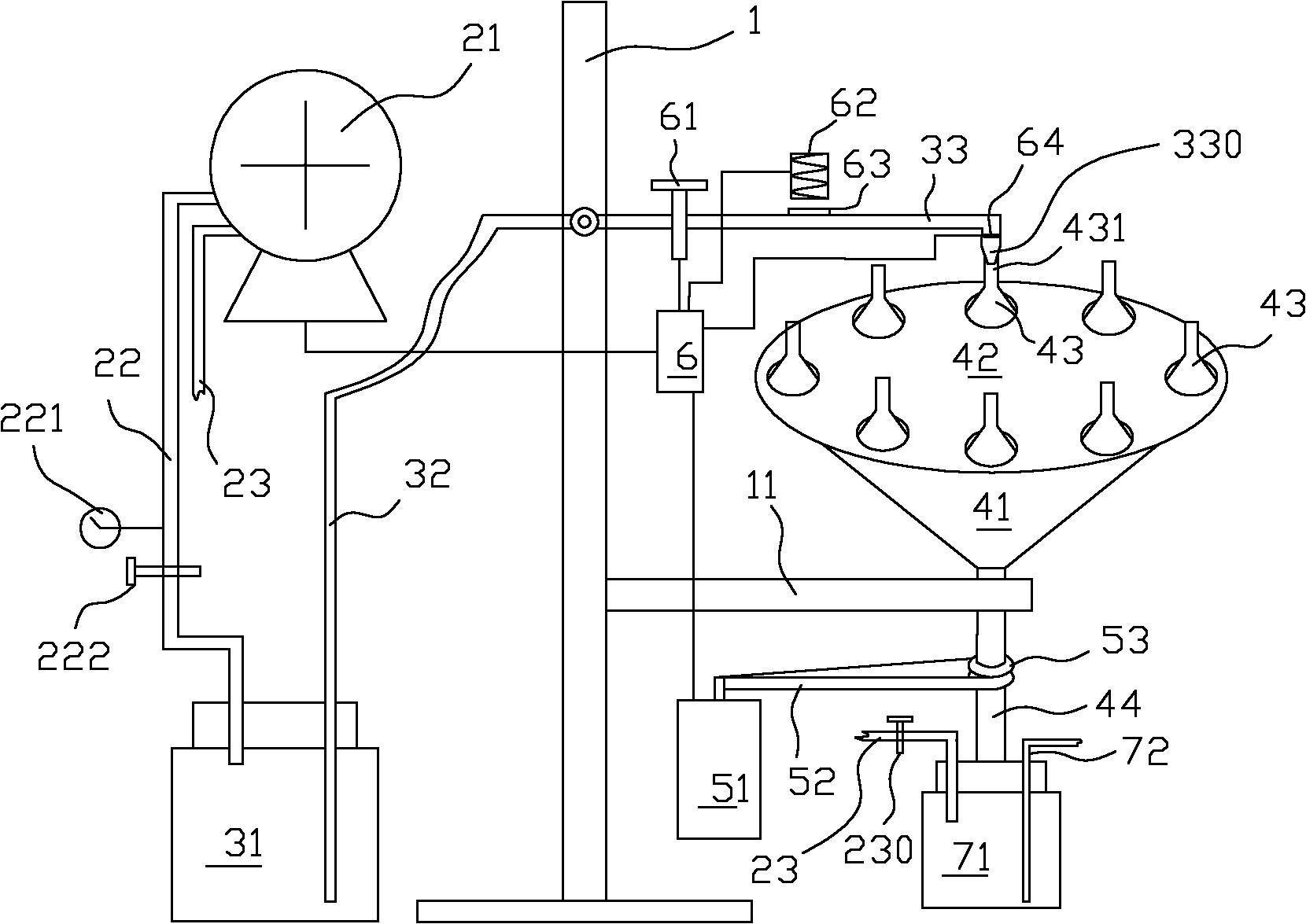

[0018] figure 1 The structure of the preferred embodiment of the present invention is schematically shown. As shown, the preferred embodiment includes a holder 1, a sample storage bottle 31, a filtrate collection bottle 71, and a plurality of filter membranes 432 (such as figure 2 ) Filter disc, filtrate collection device and control system. The bracket 1 mainly has a supporting function, and can carry multiple components including a filtrate filter device. The structure of the bracket 1 of the preferred embodiment is in the shape of "upper", and its structure shape can be selected according to the operating space and the configuration of other components, and is not particularly limited. The sample storage bottle 31 is mainly used to store the sample to be filtered, and the sample is transported to the filter tray through the sample transport pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com