Inverted-umbrella-shaped plate filter

A plate filter and inverted umbrella technology, applied in the direction of filtration and separation, moving filter element filter, separation method, etc., can solve the problems of inability to continuously filter, high moisture content of discharged filter slurry, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

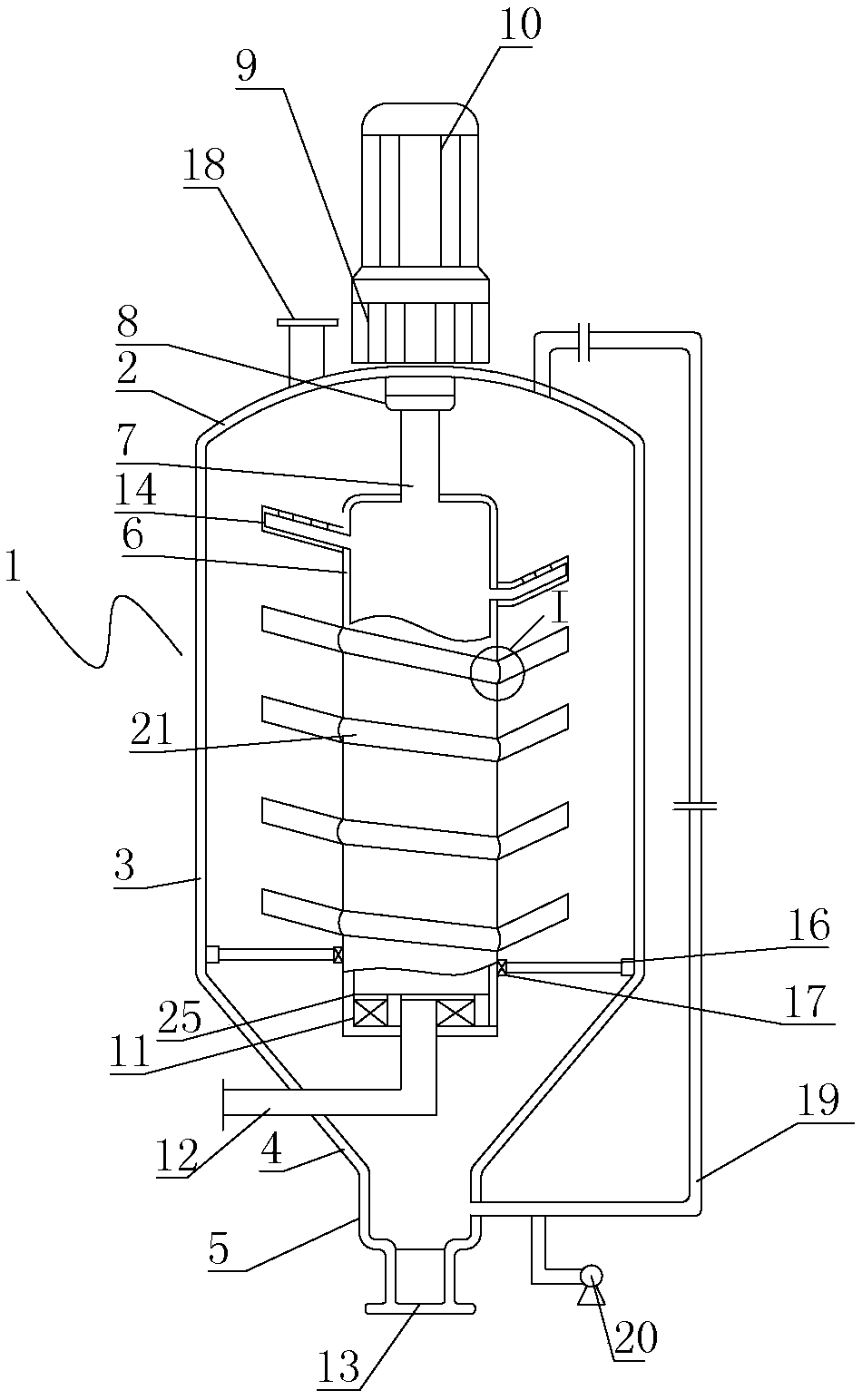

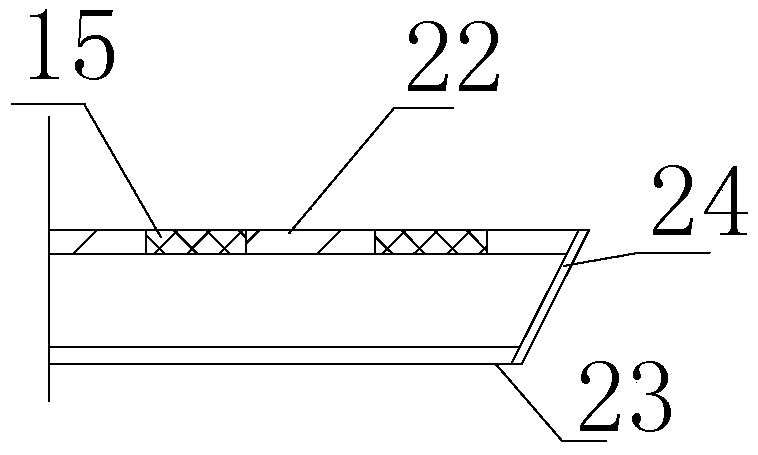

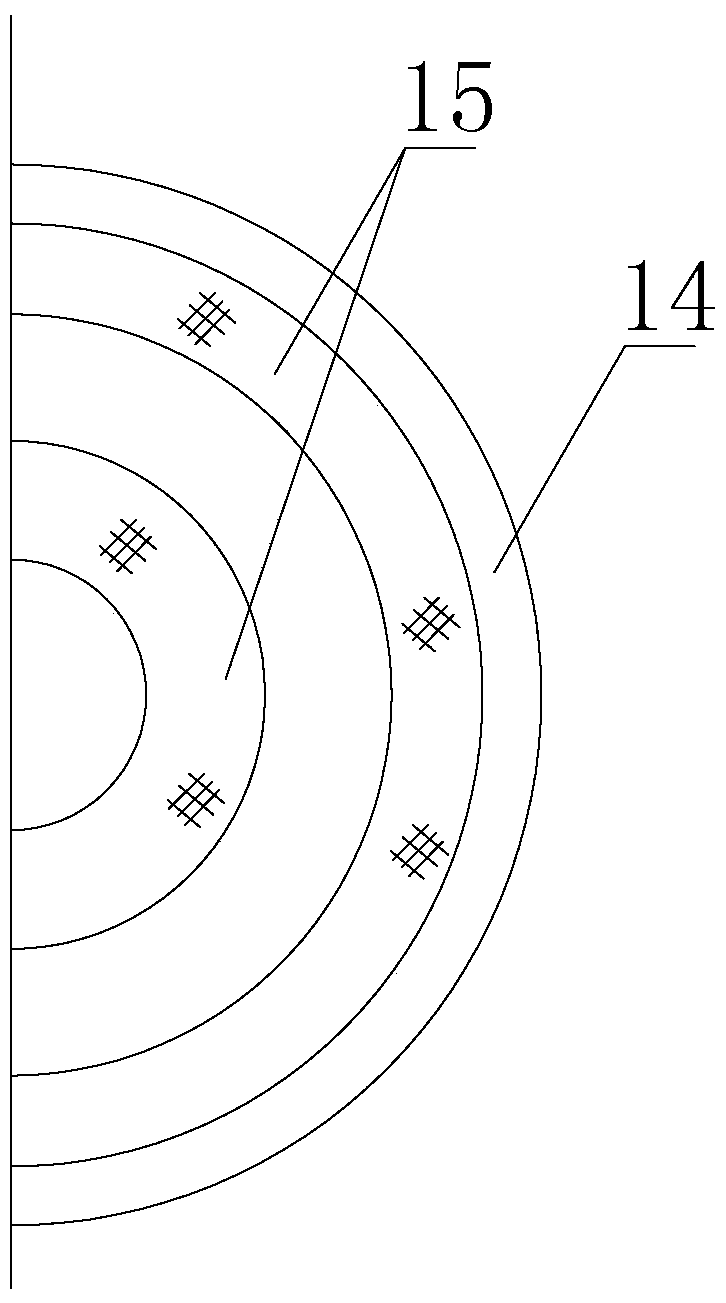

[0015] See figure 1 , figure 2 , image 3 , Figure 4 As shown, an inverted umbrella type plate filter includes a cylinder body 1. The cylinder body 1 includes an upper head 2, a middle cylindrical cylinder body 3, a lower inverted conical cylinder body 4, and a bottom straight pipe 5. Inside the cylinder body 1 A rotatable hollow tubular shaft 6 is installed, the upper end of the hollow tubular shaft 6 is connected to the reducer 9 and the motor 10 located outside the upper head 2 through the main shaft 7 and the coupling 8, and an inner bearing 11 is arranged inside the bottom end of the hollow tubular shaft 6 , the side of the inverted tapered cylinder 4 is provided with a liquid outlet through hole, and a liquid outlet pipe 12 connected to the inner bearing 1 at one end and outside the inverted tapered cylinder 4 at the other end is installed in the liquid outlet through hole, and the bottom straight pipe 5 The bottom is the slag outlet 13, and the outer surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com