Choke feeding screw conveyor

A screw conveyor and material feeding technology, which is applied in packaging and other directions, can solve the problems of easy blockage and large gas consumption, and achieve the effects of preventing overflow, high conveying speed and good gas blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

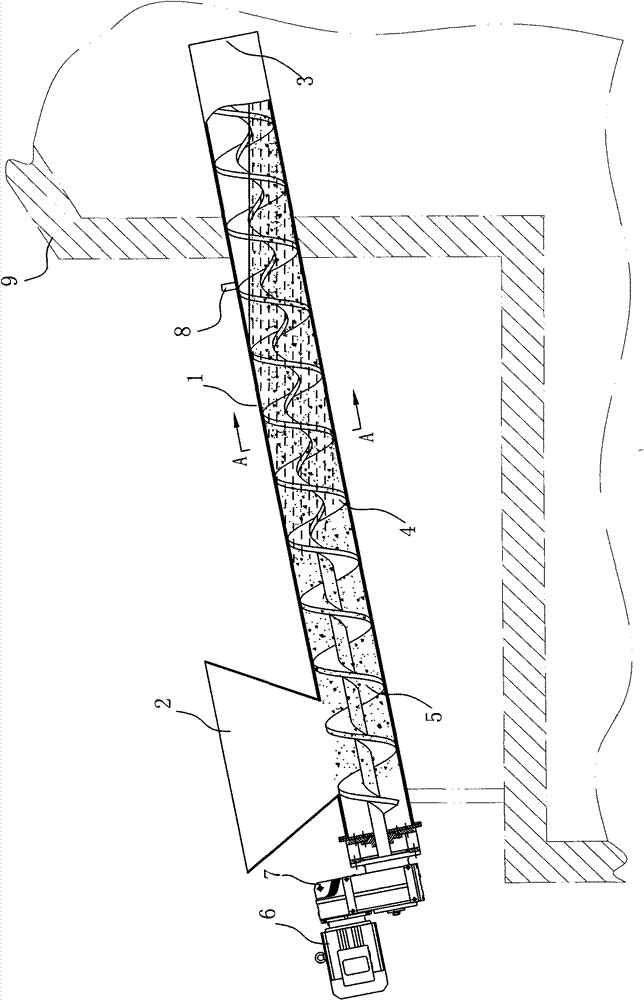

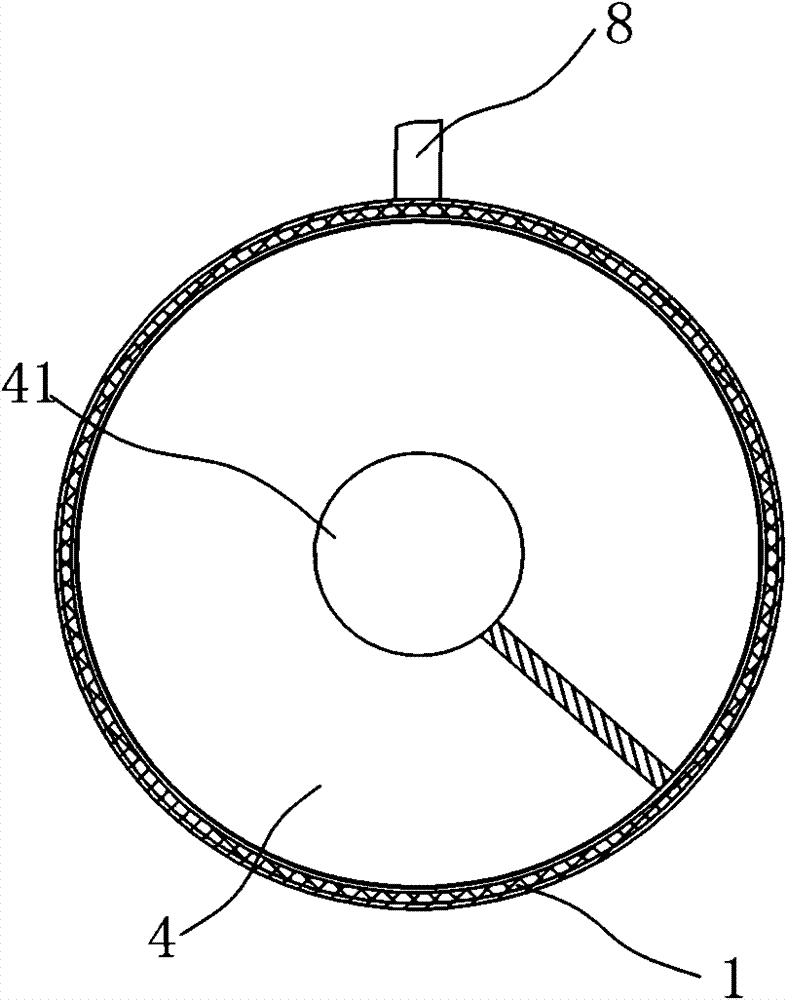

[0011] Such as figure 1 and figure 2 As shown, the air-blocking feeding screw conveyor includes a cylindrical shell 1, and the front part of the cylindrical shell 1 is provided with a discharge port 3, and the discharge port 3 extends into the airtight tank body 9, The rear portion of the cylindrical housing 1 is provided with a feed port 2, and the outer end of the cylindrical housing 1 is equipped with a driving device, the driving device includes a motor 6, and the motor 6 is connected to a reducer 7 The input end of the input end, the rear part of the discharge port of the cylindrical shell 1 is provided with a sealing water inlet 8, and the cylindrical shell 1 is provided with a shafted spiral blade 5, and the rear portion of the shafted spiral blade 5 The end is connected to the output end of the reducer 7, the front part of the shafted helical blade 5 is connected to the shaftless conveying blade 4, and the shafted helical blade 5 extends forward to the feed inlet 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com