Ammonia absorber

A technology of ammonia absorber and ammonia gas, which is applied in the field of ammonia absorber, can solve the problems of poor central absorption effect, many spray dead spots, low-load spray effect, etc., and achieve the effect of strong load fluctuation resistance and uniform spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

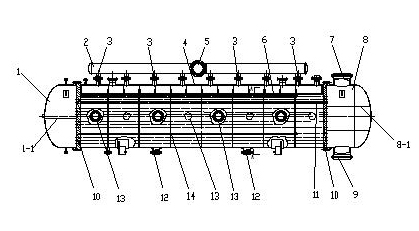

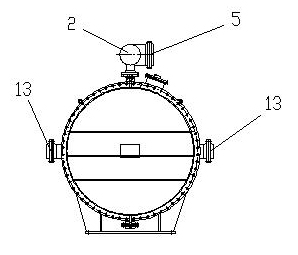

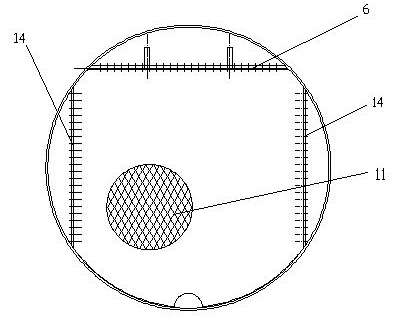

[0009] See figure 1 -3, the concrete structure of the present invention is as follows: connect the tube box 1 of band dividing plate 1-1 and the tube box 8 of band dividing plate 8-1 at the two ends of shell-and-tube type ammonia absorber housing 4, the tube box of one end 8 is provided with a circulating water inlet 9 and an outlet 7; a tube plate 10 is respectively set between the shell 4 and the tube boxes at both ends, and a corrugated tube bundle 11 is assembled between the tube plates at both ends. The technical points of improvement are: a plurality of ammonia gas inlets 13 are arranged longitudinally on both sides of the housing 4, ammonia uniform distribution plates 14 are arranged at the ammonia gas inlets on both sides of the housing 4, and uniform distribution plates 14 are set on the uniform distribution plates 14. The air intake micropores of the cloth; the concentrated ammonia water outlet 12 is set under the shell 4; the vertical water distributor 2 with the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com