Fluidized bed catalytic deoxidation method for oxygen-containing coal bed gas

A catalytic deoxidation and coalbed methane technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of high energy consumption, reduction of relative heat release, low production intensity, etc., and achieve simple equipment structure, good gas-solid contact effect, Strong ability to resist load fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

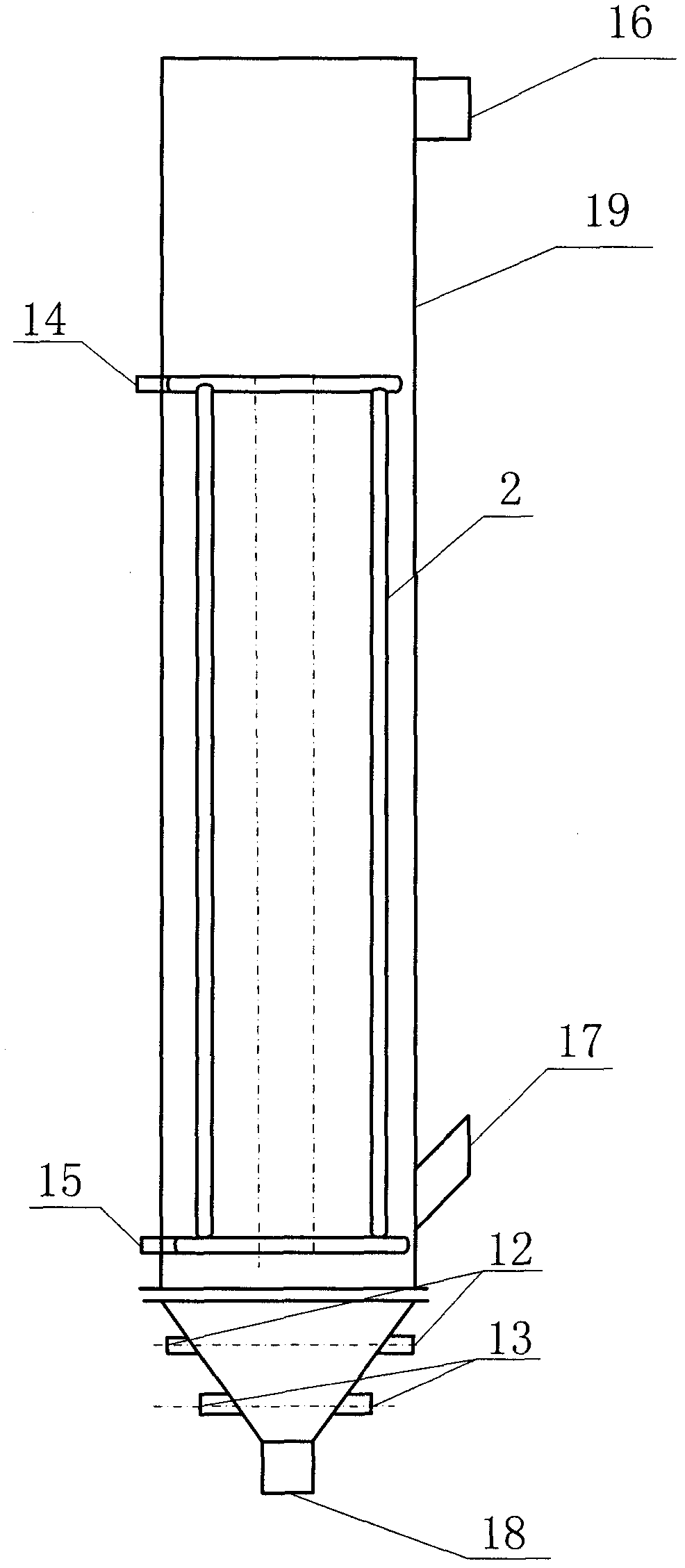

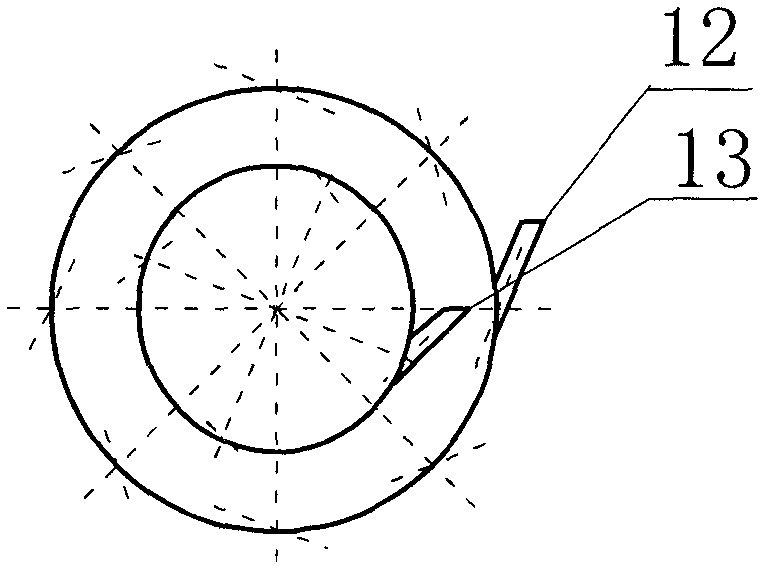

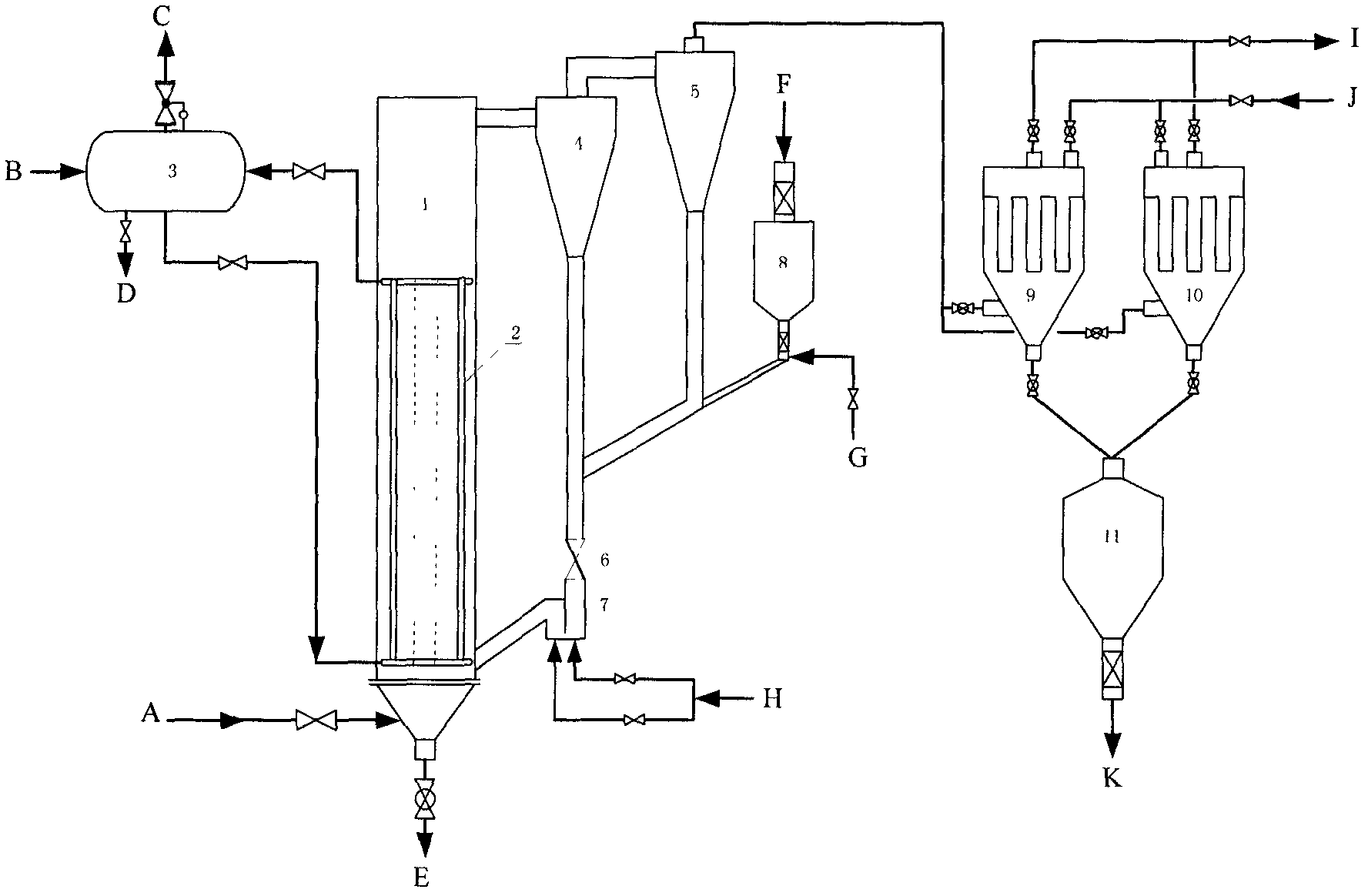

[0034]The fluidized bed deoxygenation reactor is composed of a shell 19, an oxygen-containing coalbed gas inlet nozzle, a tube heat exchanger 2, a deoxidized coalbed gas outlet 16, a deoxidation catalyst particle inlet 17, a catalyst particle discharge port 18, a cooling water inlet 15 and The steam outlet 14 is formed, and the vertical tube heat exchanger 2 is arranged in the shell 19, and the tube diameter is 25 mm. The lower end of the tubes is connected in parallel with the cooling water inlet 15, the upper end of the tubes is connected in parallel with the steam outlet 14, the cooling water inlet 15 and the steam outlet 14 are connected with the steam drum 3, and the lower part of the shell 1 is a cone with an apex angle of 60 ° There are two rows of oxygen-containing coalbed methane upper layer air inlet nozzles 12 and oxygen-containing coalbed methane lower layer air inlet nozzles 13 on the cone, and the oxygen-containing coalbed methane upper layer air inlet nozzles 12 ...

Embodiment 2

[0039] The structure of the fluidized bed deoxygenation reactor is as described in Example 1. The tube diameter of the tube heat exchanger is 38 mm, and the cone angle at the bottom of the fluidized bed reactor is 90°.

[0040] The composition of oxygen-containing coalbed methane is (volume percentage): CH 4 Content 52.40%, O 2 Content 9.93%, N 2 The content is 37.36%, and the content of other gases is 0.23%. The deoxidation catalyst is a spherical cobalt-based catalyst (30% cobalt oxide content, 67% aluminum oxide content, and 3% other metal additive content), with a particle size of 40-200 μm and a bulk density of 0.65 g / cm 3 . The operating temperature of the fluidized bed deoxygenation reactor is 480-500°C, the pressure is 0.1MPa, the operating gas velocity is 0.4-0.6m / s, and the drum pressure is 1.2-1.5MPa. All the other are the same as example 1. After the oxygen-containing coalbed methane is deoxidized by fluidized bed catalyst, the oxygen content in the deoxidized...

Embodiment 3

[0044] The structure of the fluidized bed deoxygenation reactor is as described in Example 1. The composition of oxygen-containing coalbed methane is (volume percentage): CH 4 Content 68.27%, O 2 Content 6.58%, N 2 Content 24.80%, other gas content 0.35%. The deoxidation catalyst is a spherical copper-based catalyst (the content of copper oxide is 8%, the content of aluminum oxide is 87%, and the content of other metal additives is 5%), the particle size is 60-240μm, and the bulk density is 0.68g / cm 3 . The operating temperature of the fluidized bed deoxygenation reactor is 500-520°C, the pressure is normal pressure, the operating gas velocity is 0.7-0.8m / s, and the drum pressure is 1.0-1.2MPa. All the other are the same as example 1. After the oxygen-containing coalbed methane is deoxidized by fluidized bed catalyst, the oxygen content in the deoxidized coalbed methane is 0.32%. The gas compositions of the feed gas (oxygen-containing coalbed methane) and deoxygenated ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com