Spinning winding apparatus

A kind of equipment and spinning technology, which is applied in the field of spinning and winding equipment, can solve problems such as the reduction of the mechanical resonance point of the roller, the decline of the quality of the silk thread, and the abnormal vibration of the roller, so as to reduce the number of contacts, improve the quality, and prevent the coarse details of the yarn. the effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

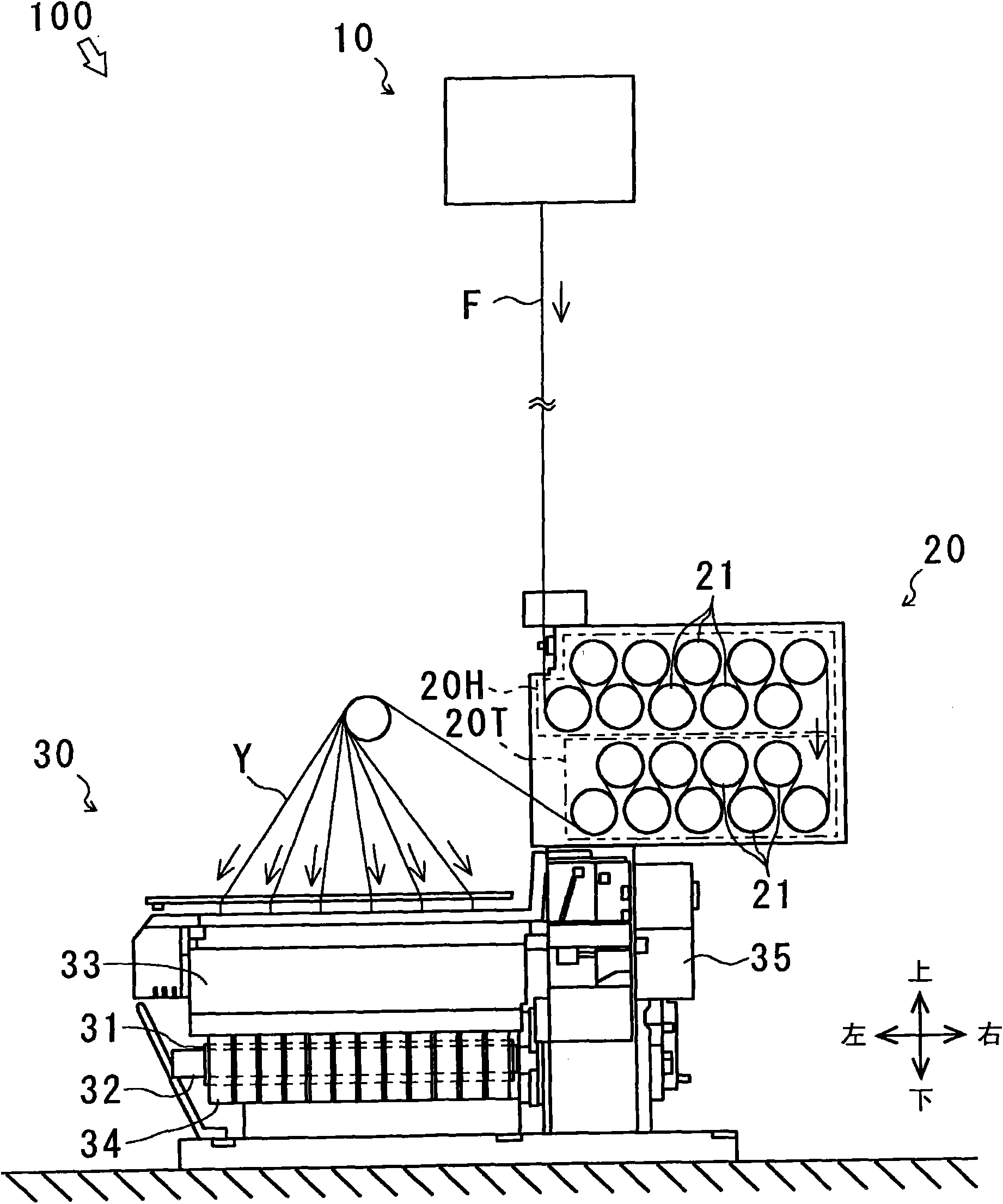

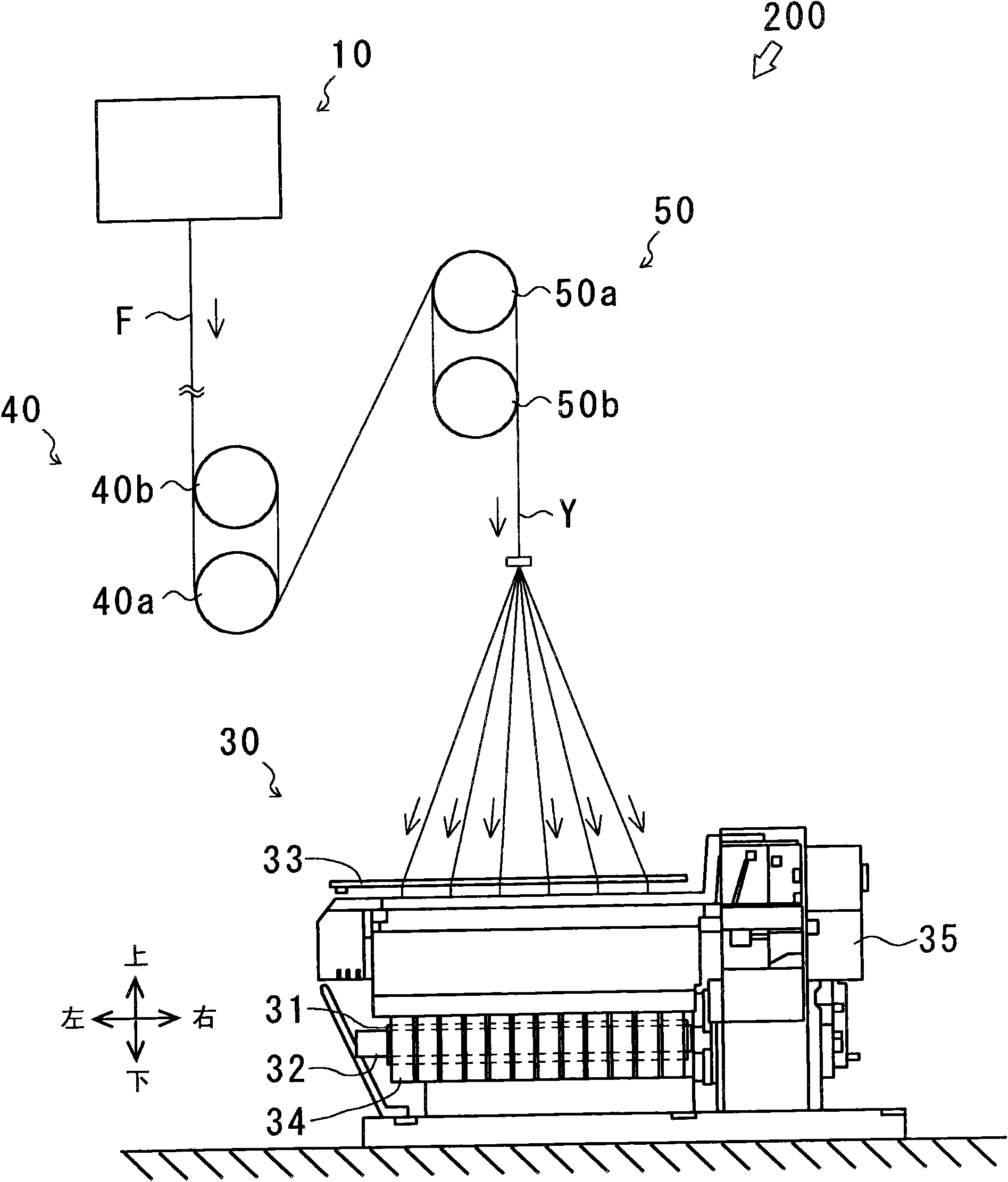

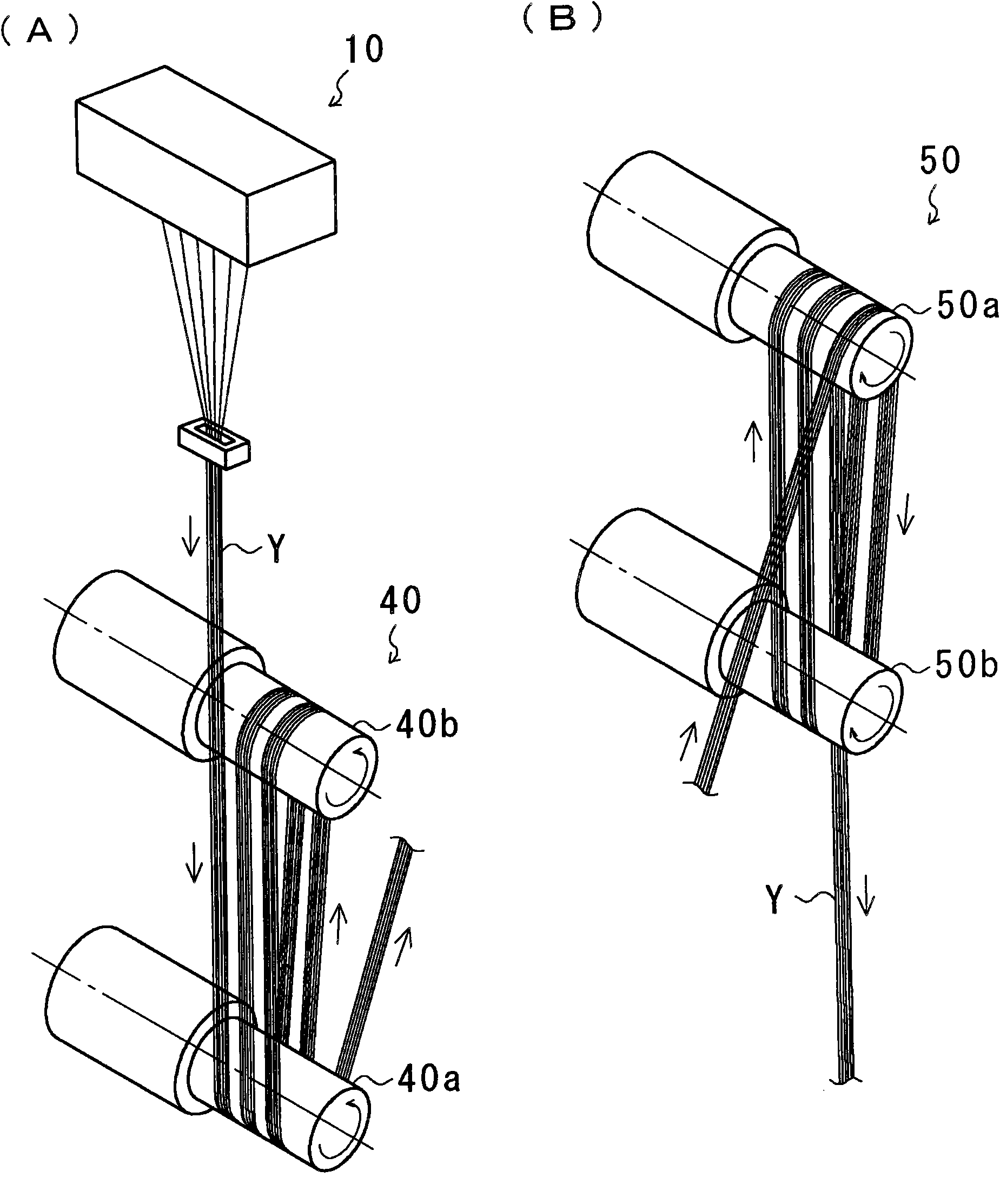

[0042] first use figure 1 The overall structure of the spinning winding equipment 100 according to the first embodiment of the present invention will be described. figure 1 It is a front view showing the overall structure of the spinning winding device 100 . In addition, the acting direction of gravity is defined as an up-down direction, and the axial direction of the bobbin holder shaft 32 included in the winder 30 is defined as a left-right direction. In addition, the arrows shown in the figure indicate the feeding direction of the monofilament F and the yarn Y.

[0043] The spinning and winding equipment 100 is mainly composed of a spinning machine 10 that spins out the single fiber F, a group of wire feed rollers 20 that stretches and heat-sets the yarn Y formed by bundling the single fiber F, and the group of wire feed rolls 20 that will A winding machine 30 for winding the fed yarn Y onto a bobbin 31 is constituted.

[0044]The spinning machine 10 is a device that spi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com