Positioning construction method for top reinforcing mesh in railway bridge support platform

A steel mesh and construction method technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inability to ensure the accuracy of the mesh, the structure cannot be reused, and the underarching of the mesh cannot be ensured. Structural stability, shortened construction period, simple and convenient conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

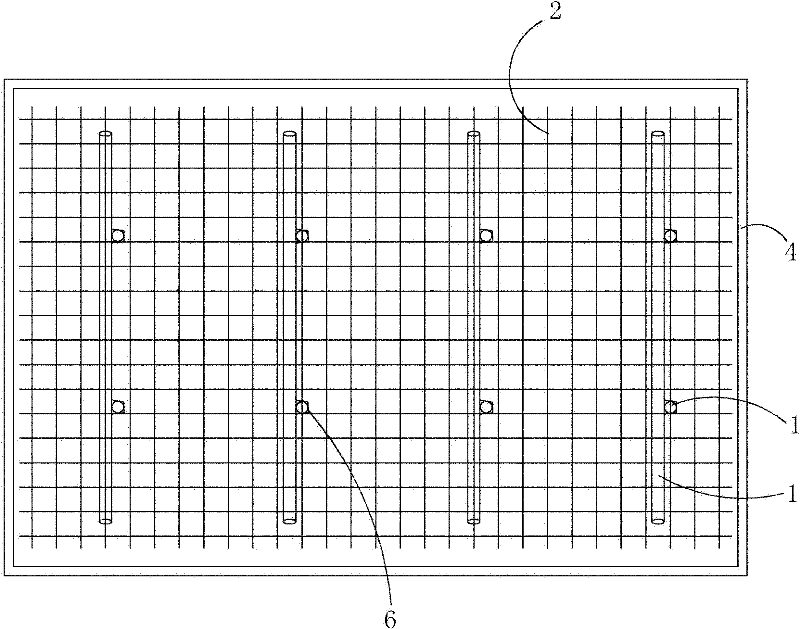

[0019] Present embodiment constructs according to following process:

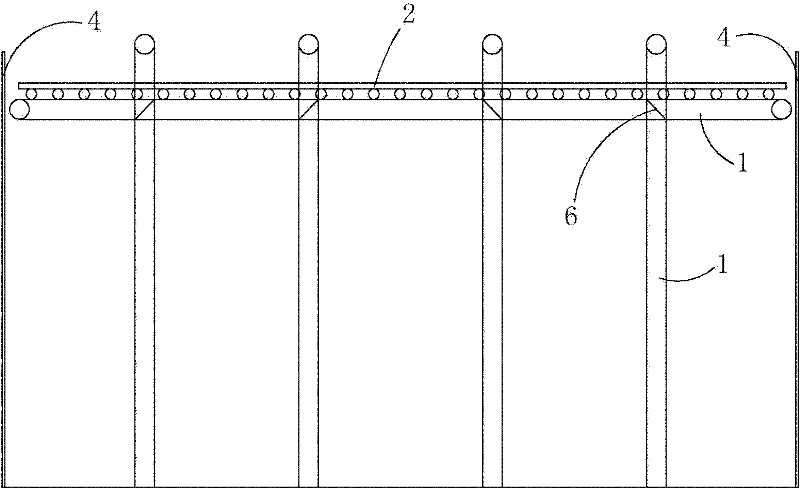

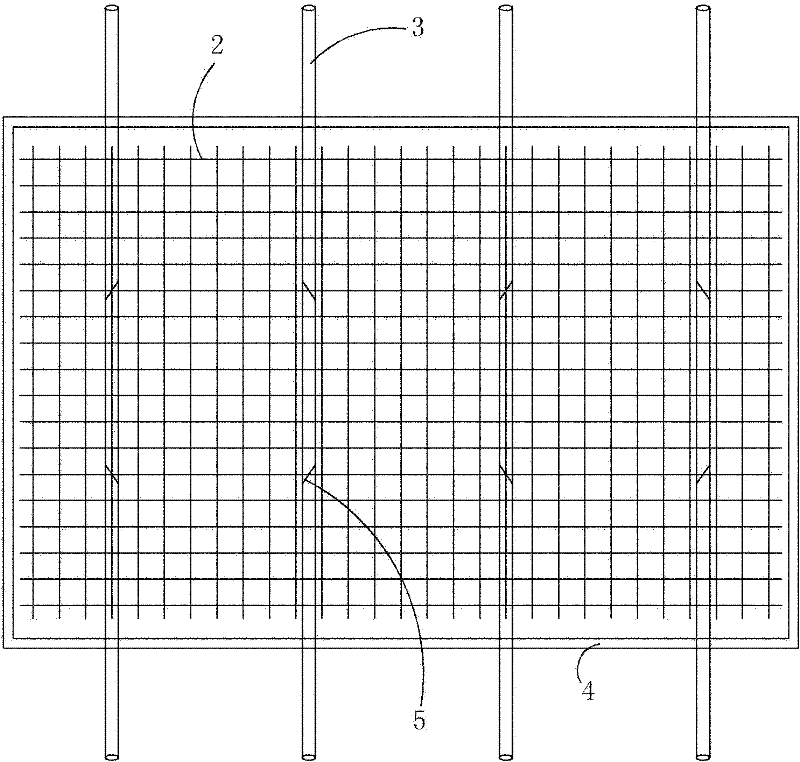

[0020] 1. Based on the pile head of the bored pile in the cap or the concrete cushion in the foundation pit, set up a steel pipe support 1 on the foundation, and the top of the steel pipe support 1 passes through the horizontal steel pipe and the vertical steel pipe in the plane where the top layer of steel mesh 2 is located. The cross fasteners 6 are fixedly connected to form a "well"-shaped plane, which constitutes a support system with a design elevation in the installation stage, which is used to support the top layer of steel mesh 2, and bear the load of the top layer of steel mesh 2 and other construction loads;

[0021] 2. Supported by the steel pipe bracket 1, the top layer of steel mesh 2 is formed by binding steel bars, and each steel pipe cross arm 3 is set above the top layer of steel mesh 2, and the two ends of the steel pipe cross arms 3 are set on the platform side formwork 4, A suspension ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com