Fuel injection valve

A technology for fuel injection valves and fuels, which is applied to fuel injection devices, charging systems, engine components, etc., and can solve problems such as insufficient improvement of valve opening or closing responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

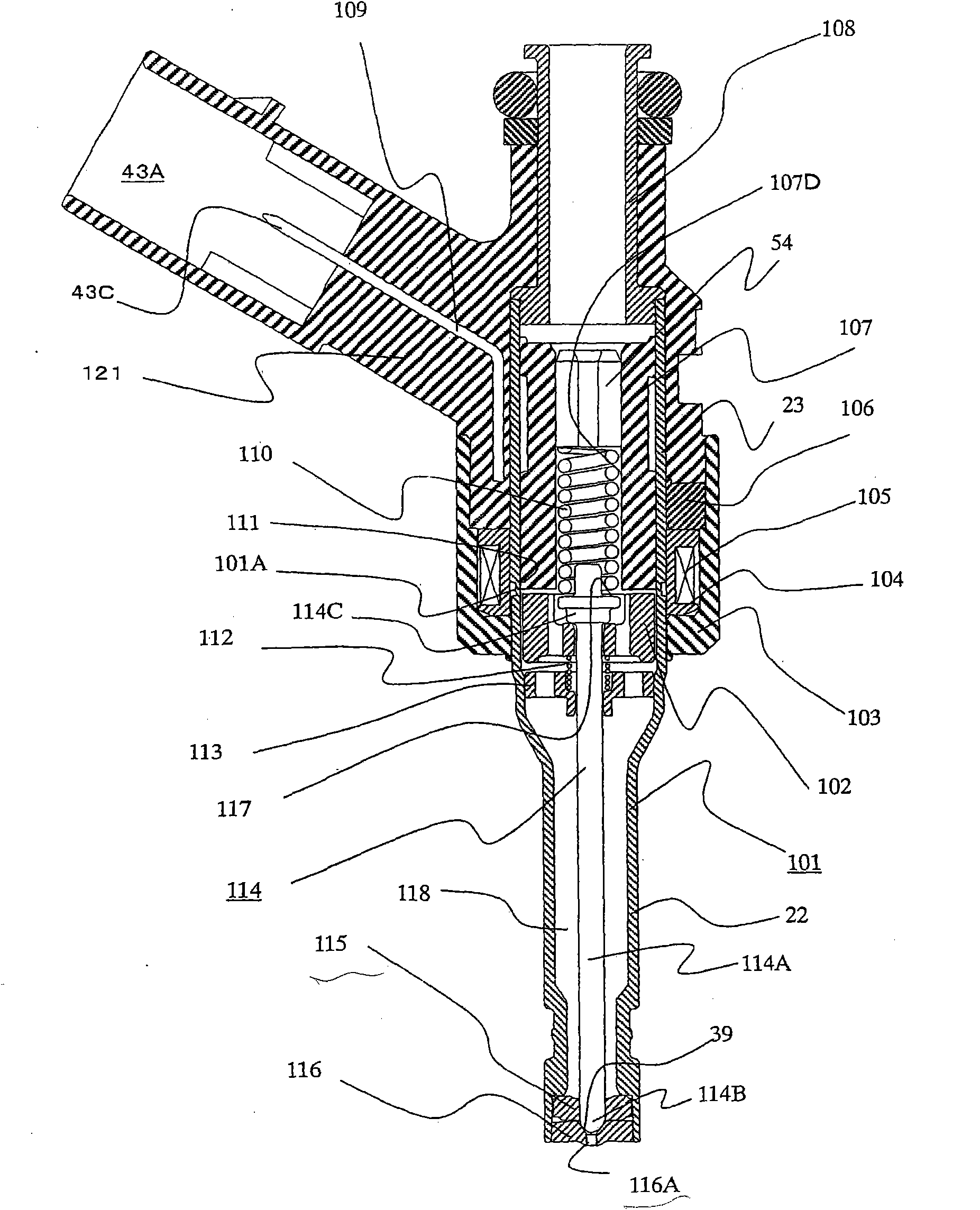

[0021] Below, use figure 1 , figure 2 The overall configuration of the embodiment will be described.

[0022] figure 1 It is a longitudinal sectional view of the fuel injection valve of the embodiment. figure 2 yes figure 1 is a partial enlarged view showing detailed features of the fuel injection valve of the embodiment.

[0023] The nozzle pipe 101 made of a metal material includes a small-diameter cylindrical portion 22 with a small diameter and a large-diameter cylindrical portion 23 with a large diameter, both of which are connected by a conical cross-sectional portion 24 .

[0024] A nozzle body is formed at the front end portion of the small-diameter cylindrical portion 22 . Specifically, a guide member 115 for guiding fuel to the center and an orifice 116 having a fuel injection port 116A are sequentially inserted into the cylindrical portion formed inside the front end portion of the small-diameter cylindrical portion. It is fixed to the cylindrical part by we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com