Dual-support rotary type compressor

A rotary compressor, double support technology, applied to rotary piston/oscillating piston pump components, mechanical equipment, machines/engines, etc., can solve the problem of poor reliability of rotary compressors and wear of crankshaft and compression components Increased, did not realize the core gap fit and other problems, to achieve the effect of improved reliability, low torque power consumption, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

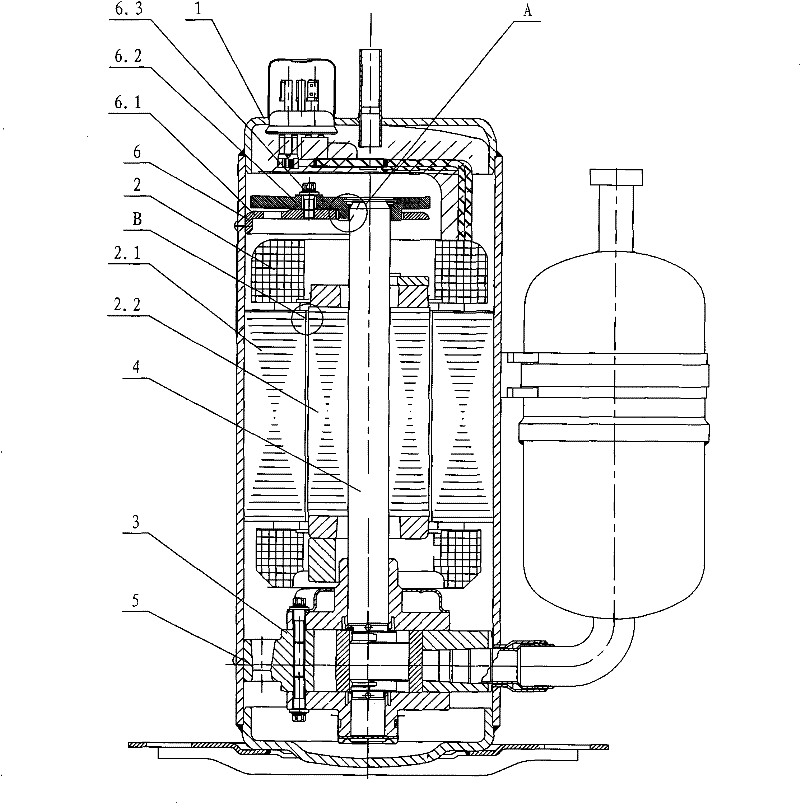

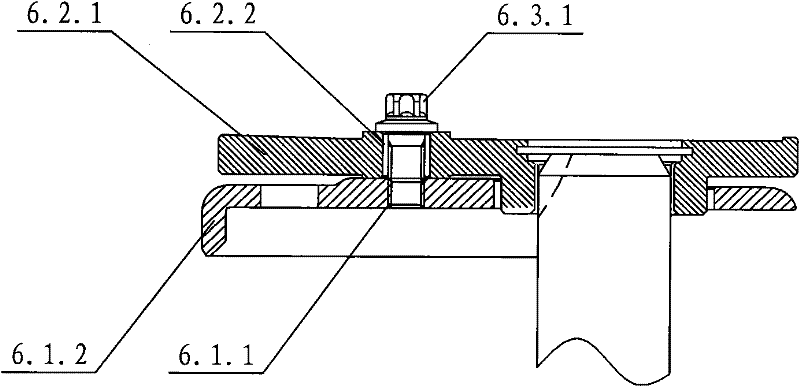

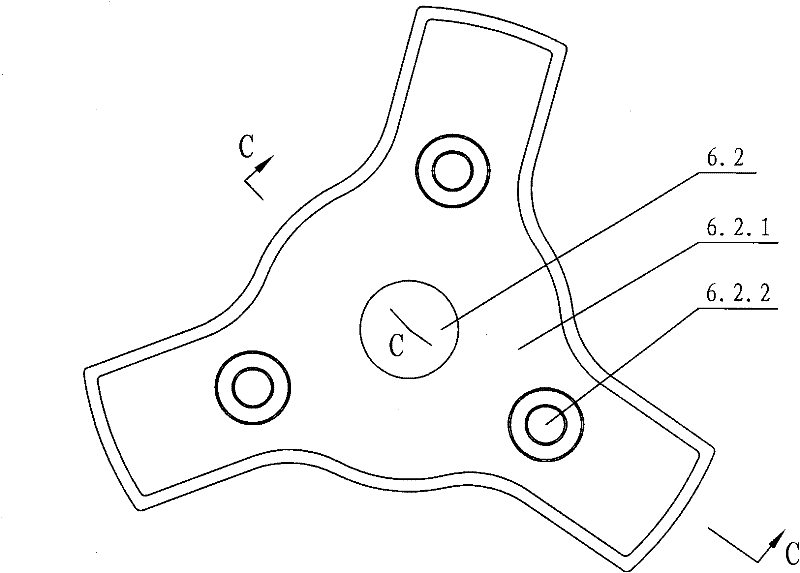

[0021] see Figure 1-Figure 6 , this double-supported rotary compressor includes a motor assembly 2 and a compression assembly 3 arranged in the casing 1, the motor assembly 2 includes a stator 2.1 fixed on the casing 1 and a rotor 2.2 tightly combined with the crankshaft 4 inside The compression assembly 3 includes a cylinder, a crankshaft 4, and main bearings and auxiliary bearings arranged on the upper and lower end surfaces of the cylinder. The eccentric part of the crankshaft 4 is in contact with the piston in the cylinder. The compression assembly 3 also includes a The first support 5 and the second support 6 on the top, the first support 5 is located on the compression assembly 3 at one end of the motor assembly 2, the second support 6 is located at the other end of the motor assembly 2, and the second support 6 passes through the bearing set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com