Tube in shape like Chinese character 'pin' with polyethylene winding structure wall and production process thereof

A polyethylene pipe and polyethylene technology, which is applied in the direction of pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of high product cost, heavy weight, and many pipe materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

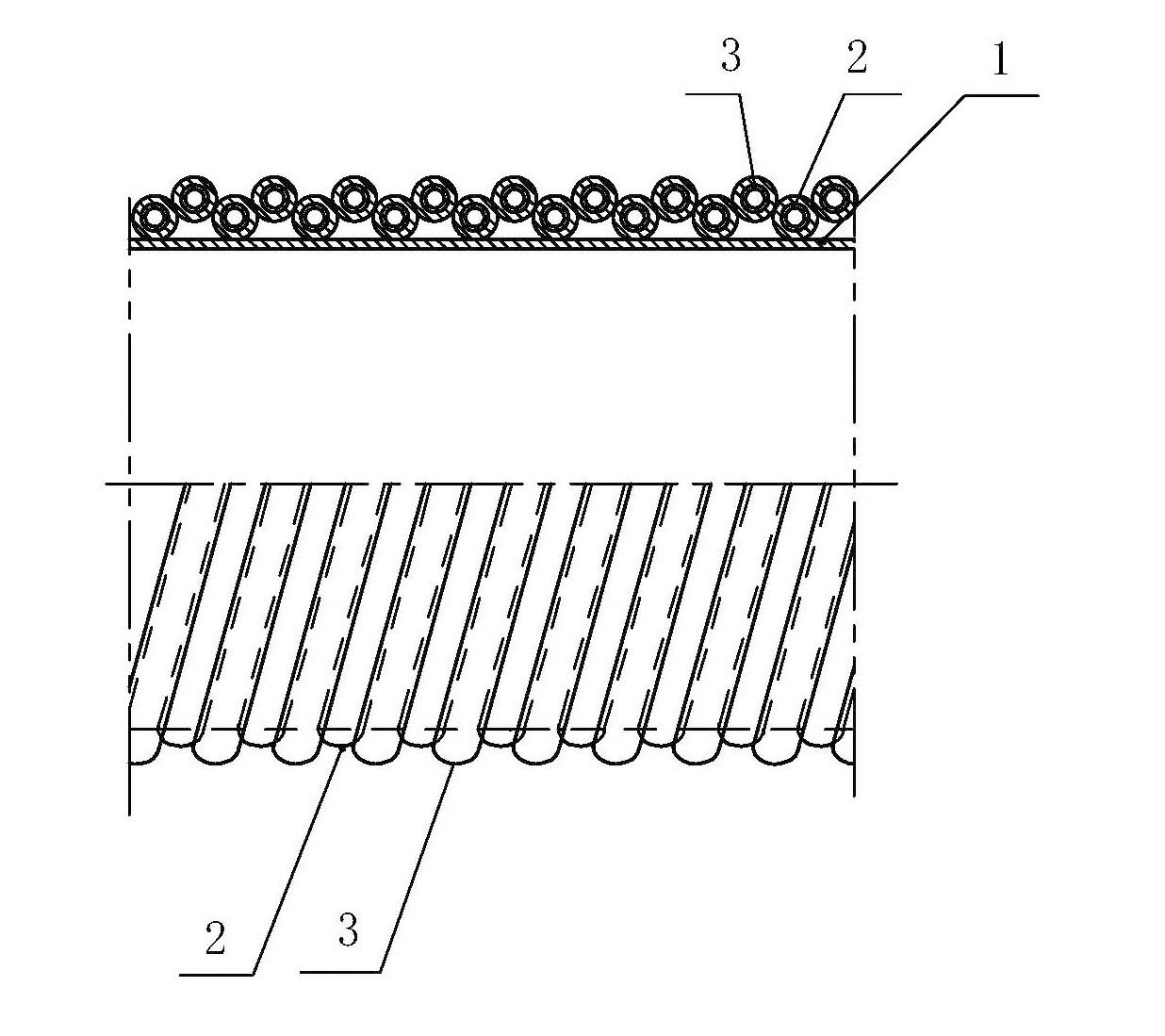

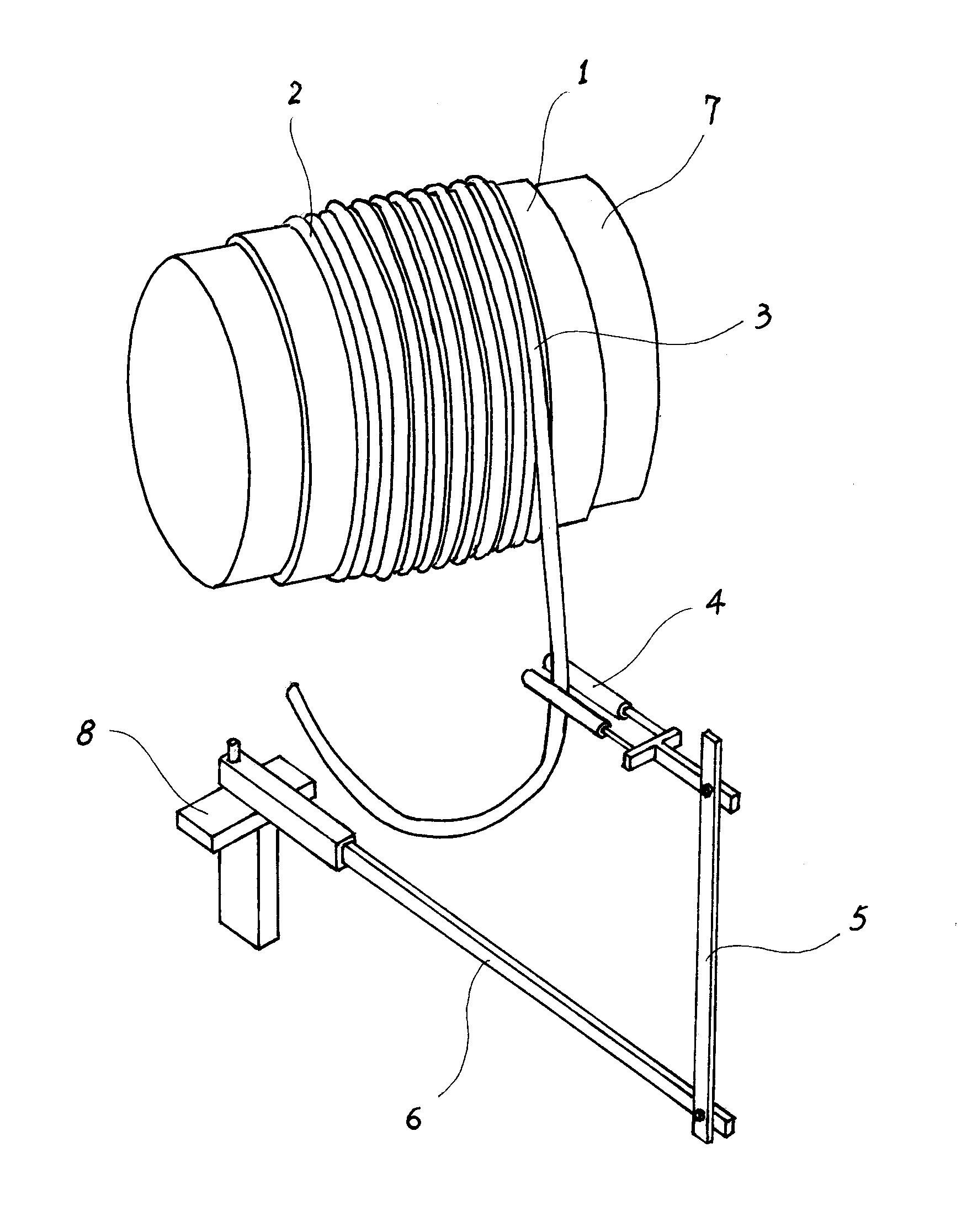

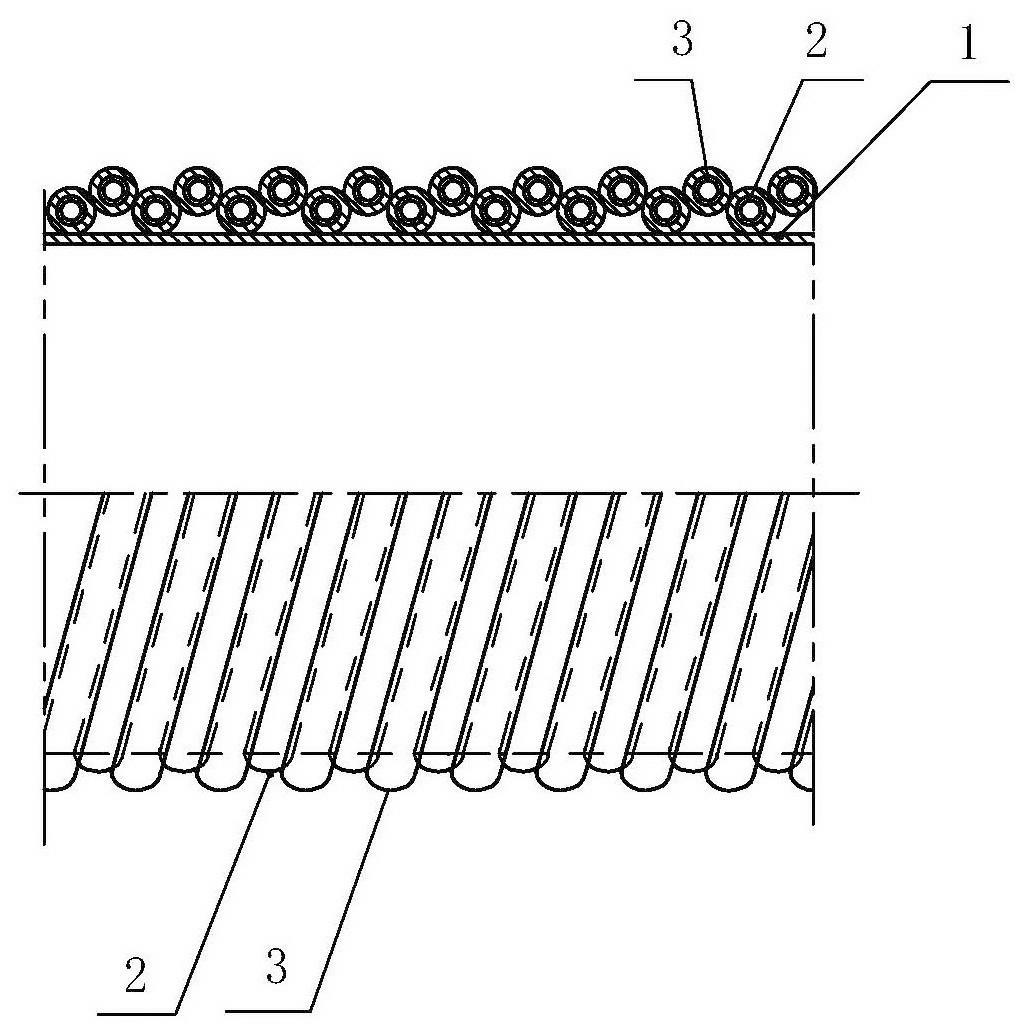

[0017] As shown in Fig. 1, the polyethylene winding wall-shaped pipe of the present invention is a hollow rib pipe spirally wound outside the inner polyethylene pipe wall 1, and the hollow rib pipe is composed of a PP skeleton pipe coated with a polyethylene layer. The rib tube has two layers. The rib tubes of each layer are arranged at intervals, the second layer of rib tubes 3 is superimposed and wound on the first layer of rib tubes 2, and the rib tubes 3 and rib tubes 2 are arranged tangentially in the shape of a character. fixed by welding.

[0018] The pipe material of the present invention can be provided with a socket at one end and a socket at the other end, a circle of electric heating elements are embedded in the inner wall of the socket, and both ends of the electric heating element protrude from the inner wall of the socket. Setting the socket and the socket can make the operation of the pipe connection more convenient.

[0019] figure 1 , figure 2 Shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com