Measuring tool for eccentric pin hole of medium-high pressure internal-external cylinder of steam turbine

A measuring tool, high and medium pressure technology, applied in the direction of mechanical measuring devices, measuring devices, mechanical devices, etc., can solve the problems of eccentric pins with large measurement errors, high labor intensity, and long assembly time, so as to achieve small measurement errors and reduce labor costs. strength, saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

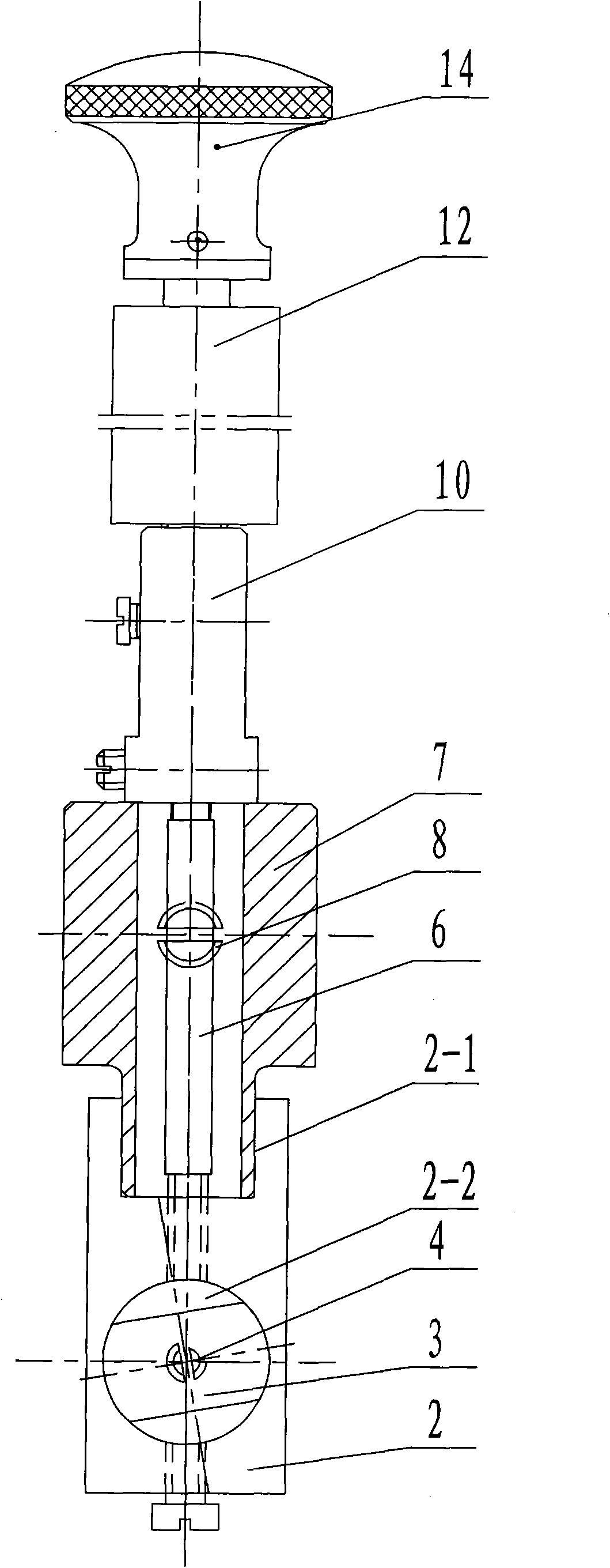

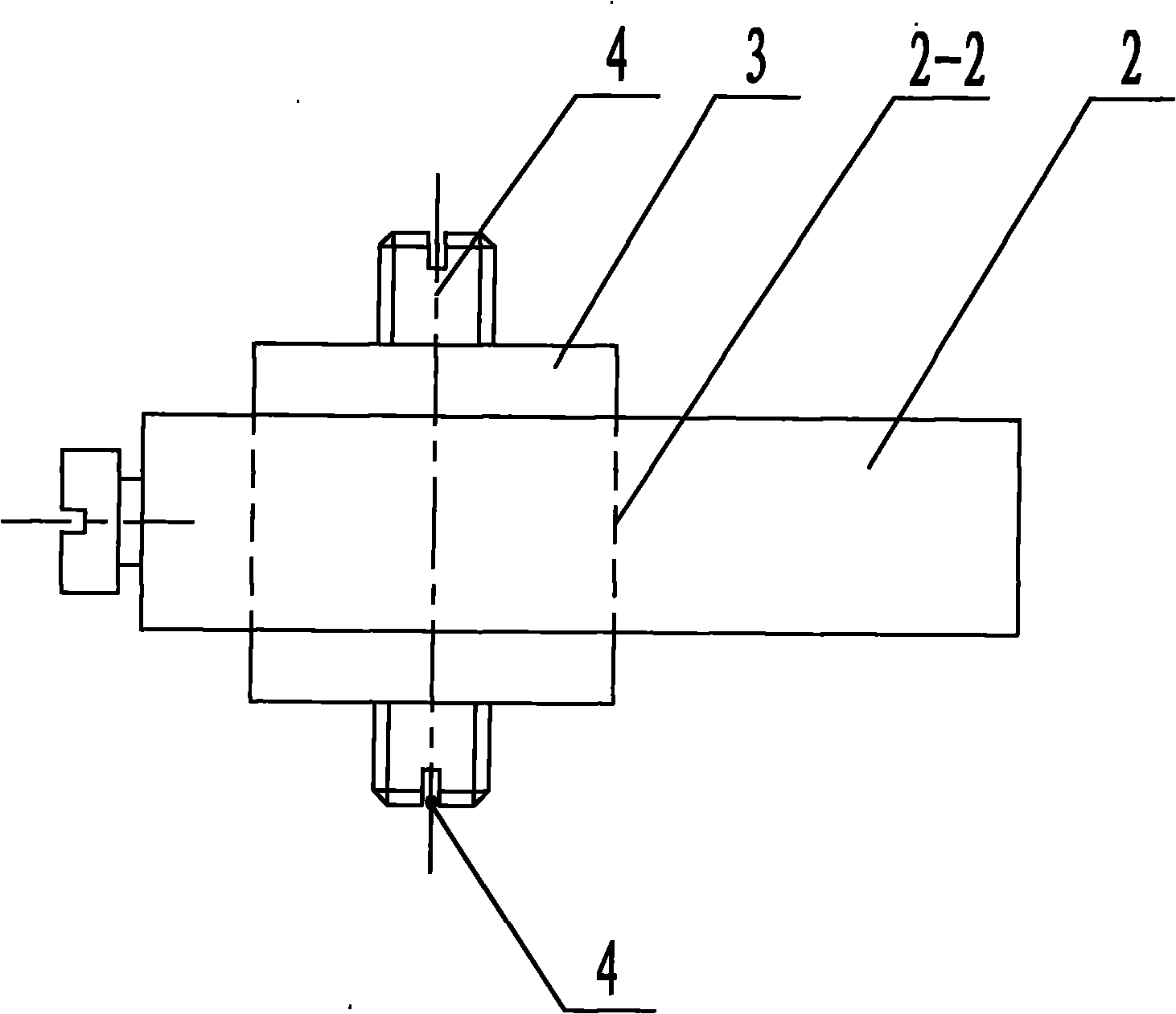

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the tool for measuring the eccentric pin holes of the inner and outer cylinders of steam turbines in this embodiment includes a slider 2, a key 3, two first set screws 4, a stud bolt 6, a positioning sleeve 7, and a second set screw 8 and connecting shaft 10; one end of the slider 2 has a groove 2-1 along the axial direction of the slider 2, and a through hole 2-2 is opened on the slider 2 along the radial direction of the slider 2, so The key 3 is installed in the through hole 2-2, and the upper end and the lower end of the key 3 all extend out of the slider 2, and a first set screw 4 is respectively installed on the upper end surface and the lower end surface of the key 3, and the positioning sleeve One end of 7 is installed in the groove 2-1, the positioning sleeve 7 is transitionally fitted with the groove 2-1, the stud bolt 6 is installed in the positioning sleeve 7, and the...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the measuring tool of this embodiment is further provided with a long rod 12 and a knob 14 , one end of the long rod 12 is fixedly connected to the connecting shaft 10 , and the other end of the long rod 12 is fixedly connected to the knob 14 . Such setting is convenient for the operator to measure when the cylinder size is large. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. The knob 14 of the present embodiment is knurled. With such arrangement, the friction is increased, which is convenient for the operator to use. Other compositions and connections are the same as those in the second embodiment.

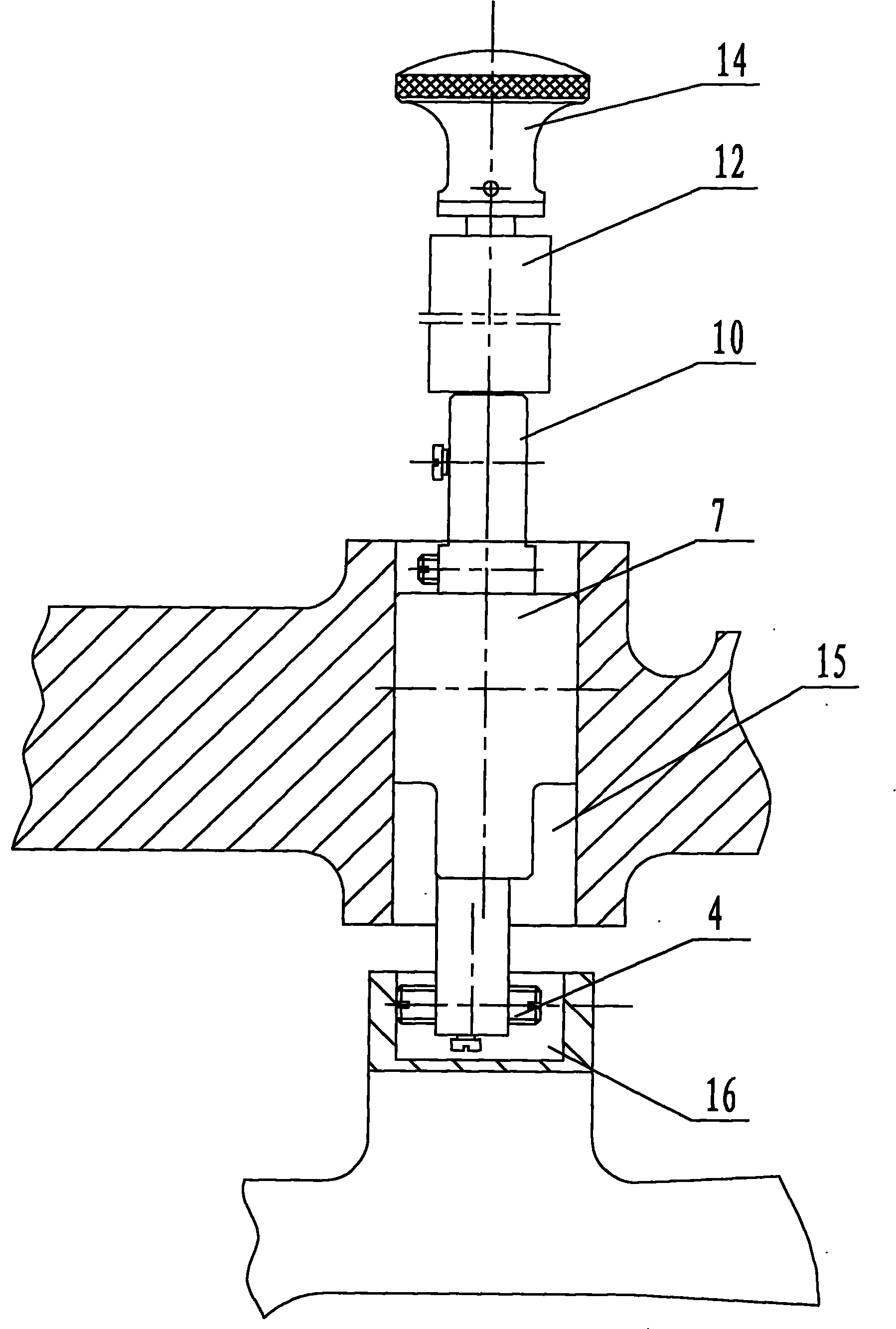

[0010] The using method of measuring tool of the present invention is as follows (see image 3 ): When using the measuring tool, first install the key 3 on the slider 2, use the stud bolt 6 to assemble the positioning sleeve 7, the slider 2 and the connecting shaft 10, and connect the long rod 12 to the connecting shaft 10 , and finally the knob 14 is connected with the long rod 12 . After all parts are combined and installed, insert the positioning sleeve 7 into the pin hole 15 of the outer cylinder first, then press the side of the slider 2 on the keyway 16 of the inner cylinder, and then turn the long rod 12 to lock it, and finally put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com