Machine tool spindle temperature measurement device and measurement method thereof

A technology for temperature measurement and machine tool spindles, applied in measuring devices, measuring heat, thermometers, etc., can solve problems such as difficult to directly measure the temperature of the machine tool spindle spindle core, reduce the machining accuracy of machine tools, and high defective rate, and reach the scope of application Wide, improved ease of use, fast response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

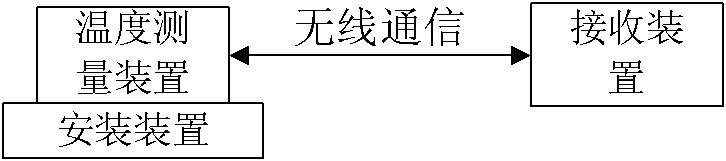

[0036] Such as figure 1 As shown, the method and device for measuring the temperature of the machine tool spindle are composed of three parts: a temperature measuring device, a mounting device and a receiving device, and the temperature measuring device is fixed on the mounting device.

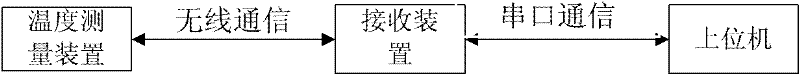

[0037] Such as figure 2 As shown, the temperature measurement device is fixed inside the measured spindle through the installation device, the spindle temperature signal is collected through the digital sensor and the monitoring data is sent to the receiving device through wireless communication. After receiving the monitoring data, the receiving device transmits the data through the serial port to PC.

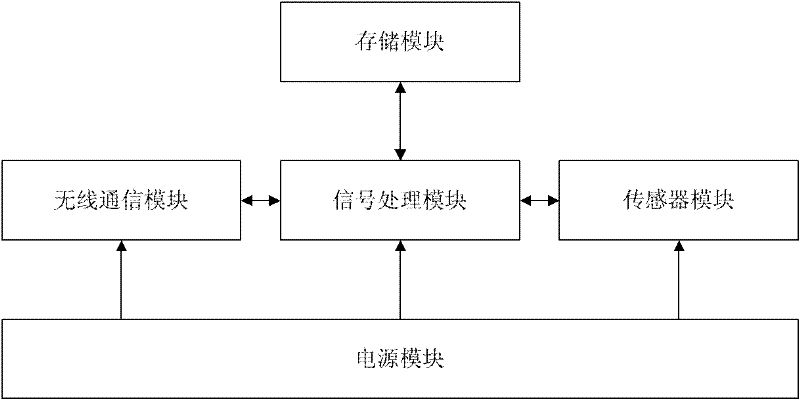

[0038] Such as image 3As shown, the temperature measuring device is composed of a sensor module, a signal processing module, a wireless communicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com